Encapsulating method and encapsulating module for LED chip

A technology of LED chip and packaging method, which is applied in the direction of electrical components, electric solid devices, circuits, etc., to achieve excellent heat dissipation characteristics, high optical characteristics, and reduce the effect of thermal interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

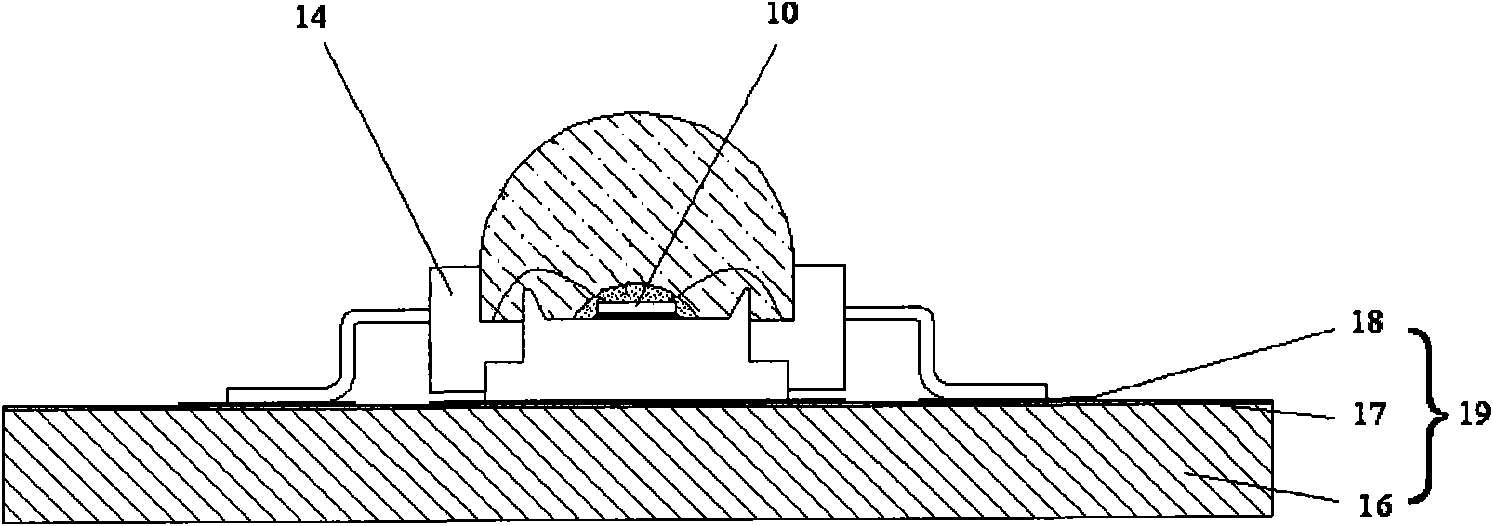

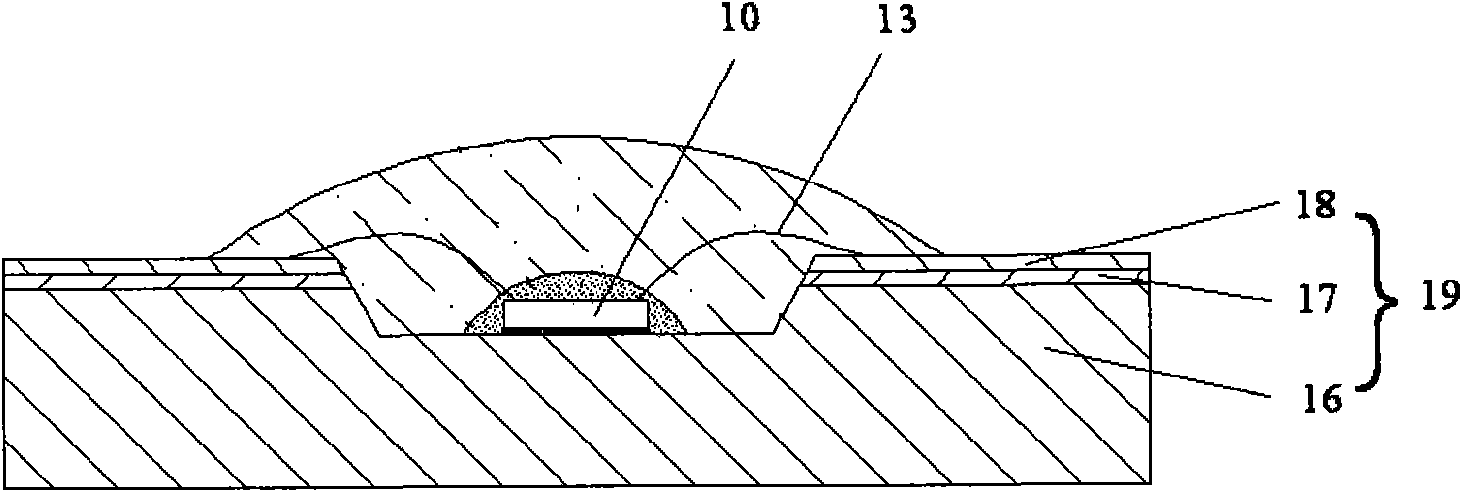

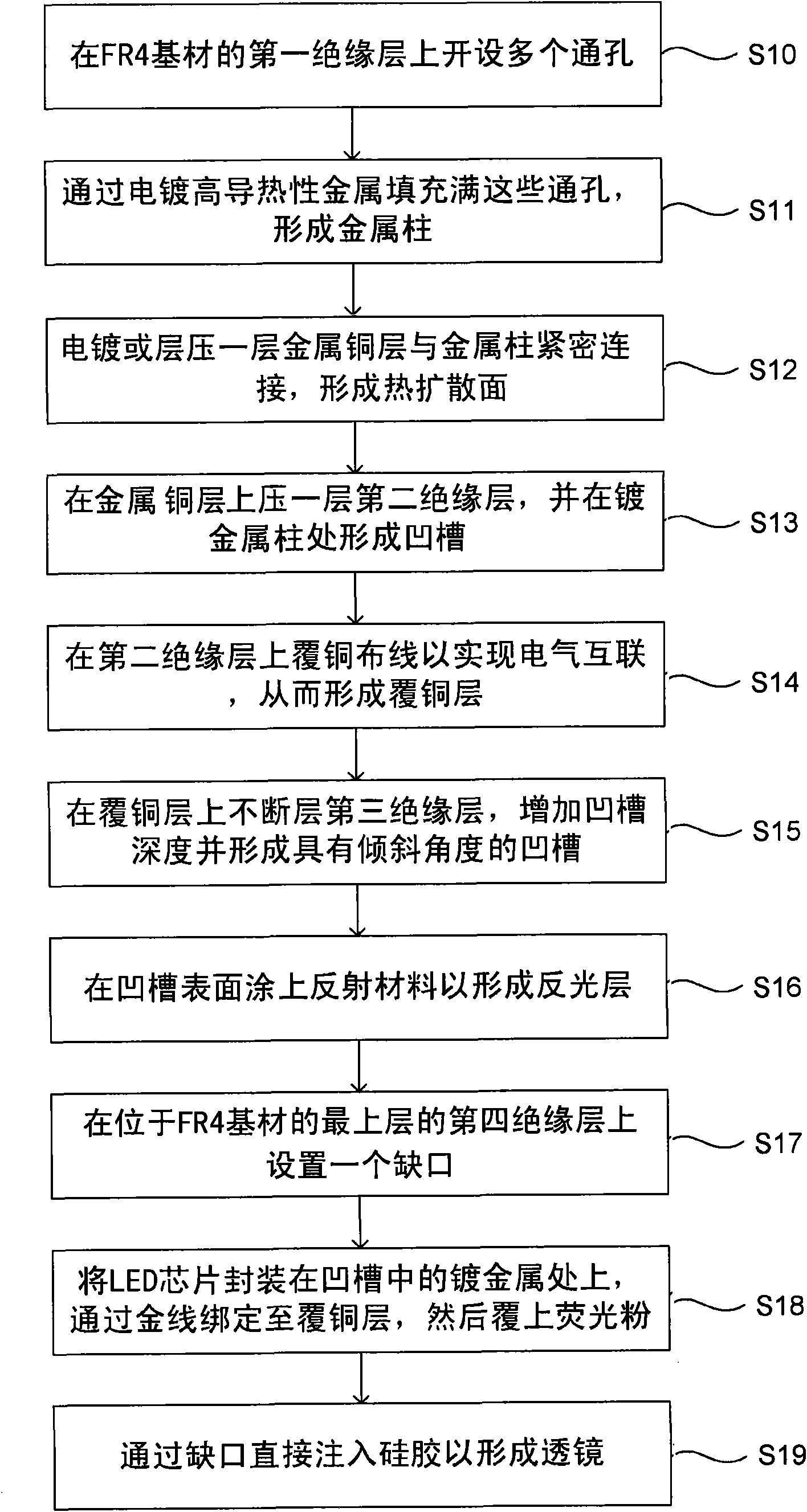

[0046] image 3 The flow of the first embodiment of the LED chip packaging method of the present invention is shown. See image 3 , the following is a detailed description of each step of the LED chip packaging method of this embodiment.

[0047] Step S10: opening a plurality of through holes on the first insulating layer of the FR4 substrate. The respective through holes may be spaced an equal distance apart.

[0048] Step S11 : filling these through holes with electroplating metal with high thermal conductivity to form metal pillars. Generally speaking, electroplated copper is used to fill these via holes to form copper pillars.

[0049] Step S12: electroplating or laminating a metal copper layer, and closely connecting with the metal pillars to form a heat diffusion surface.

[0050] Step S13: laminating a second insulating layer on the metal copper layer, and forming grooves at the metal-plated posts.

[0051] Step S14 : cladding copper wiring on the second insulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com