Wafer-level packaging structure for improving response rate of thermopile infrared detector

An infrared detector, wafer-level packaging technology, applied in electrical radiation detectors, measuring devices, microstructure technology, etc. The effect of multiple losses, improved utilization, and improved response rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

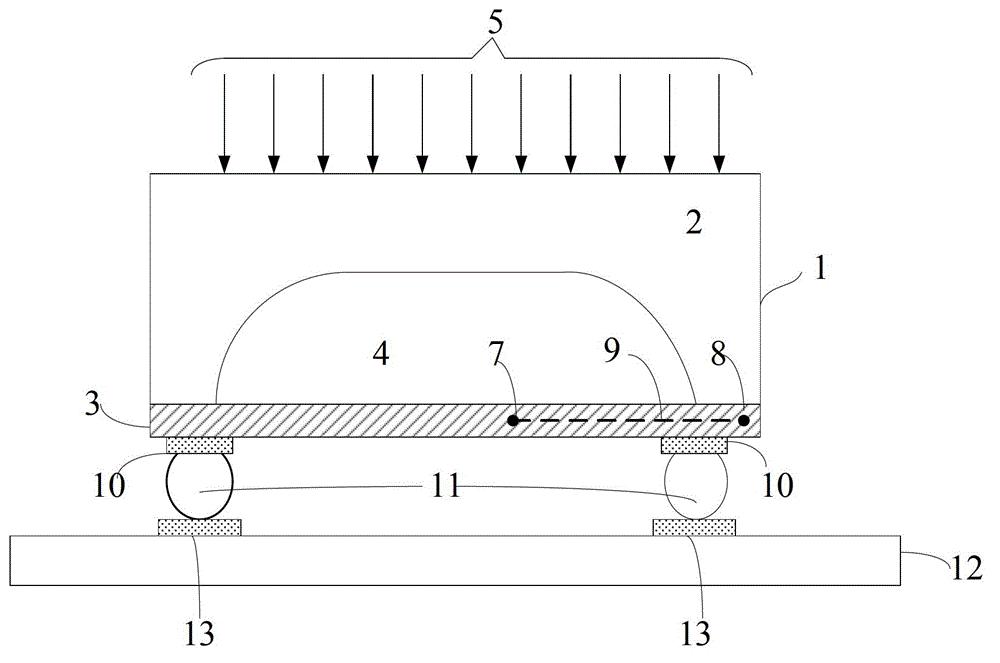

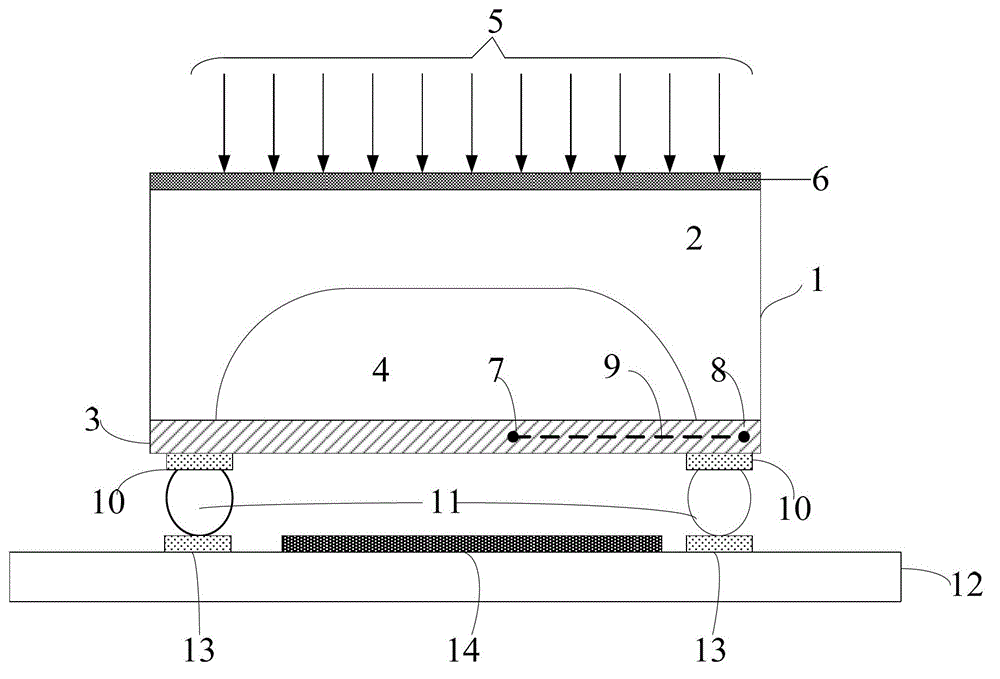

[0025] Embodiment one, such as figure 2 As shown, a thermopile infrared detector 1 includes a silicon substrate 2 , a suspension film 3 , and a cavity structure 4 , wherein the suspension film 3 contains a thermopile structure 9 .

[0026] The thermopile structure 9 is made inside the suspension membrane 3 through the existing technology, and the thermopile structure 9 is usually formed by a series of thermocouple bars connected in series. One end of the thermopile structure 9 is a hot end 7 and the other end is a cold end 8 .

[0027] An infrared anti-reflection film 6 is grown on the back of the silicon substrate 2 facing the infrared radiation source 5. In this embodiment, the infrared anti-reflection film 6 is uniformly grown on the back of the silicon substrate 2 directly by coating technology. Commonly used coating methods include vacuum evaporation, chemical phase deposition, sol-gel coating and other methods.

[0028] Then, lead electrodes 10 are drawn out on the sus...

Embodiment 2

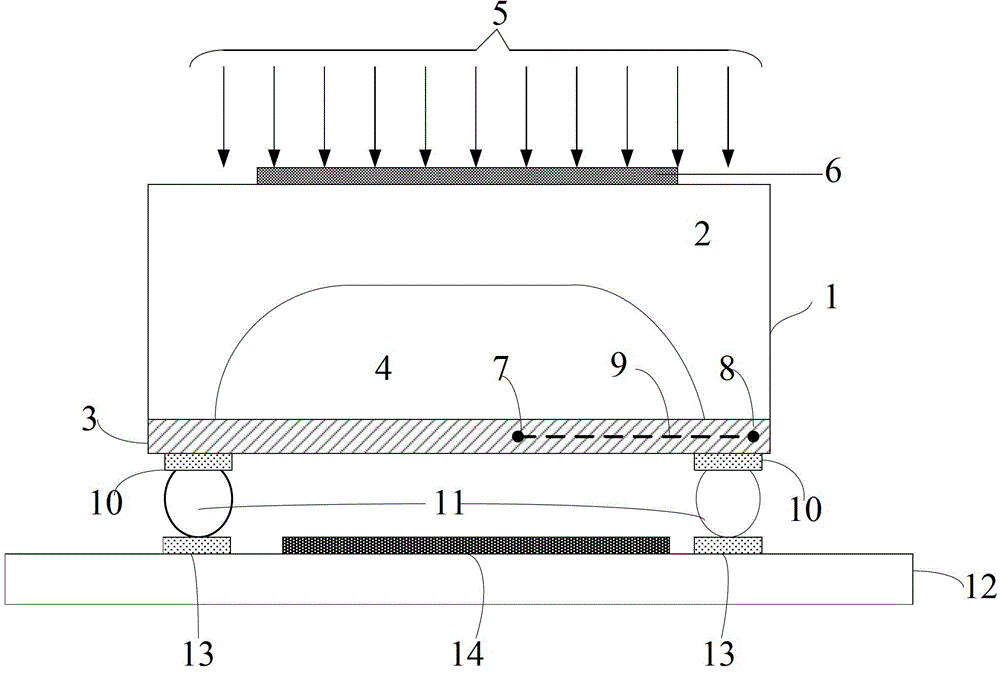

[0031] Embodiment two, such as image 3 As shown, it is a further improvement on the basis of Embodiment 1. The infrared anti-reflection coating 6 in the corresponding area on the back of the silicon substrate 2 above the cold end 8 is removed, so that the patterned infrared light is formed on the back of the silicon substrate 2. AR coating. The patterned infrared anti-reflection film covers the back area of the silicon substrate 2 above the cavity structure 4 . The structure in other aspects is the same as in Embodiment 1. The detailed process of forming a patterned infrared anti-reflection coating is as follows:

[0032] The infrared anti-reflection film 6 is evenly grown on the back side of the silicon substrate 2 facing the infrared radiation source 5 by coating technology, and the photoresist is spin-coated on the surface of the infrared anti-reflection film of this layer, and then the anti-reflection film position needs to be removed (the cold of the thermopile The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com