Patents

Literature

60results about How to "Maintain production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

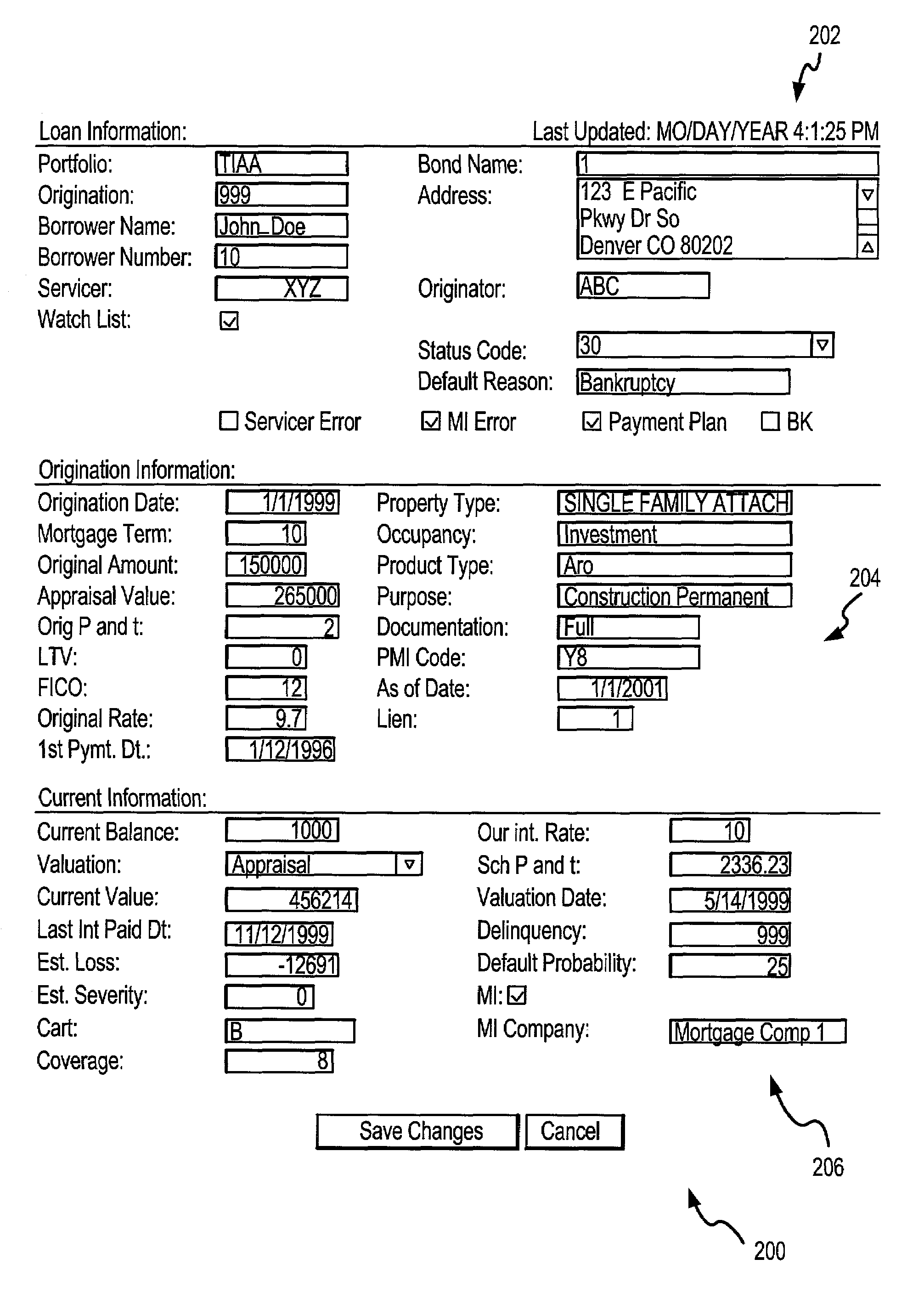

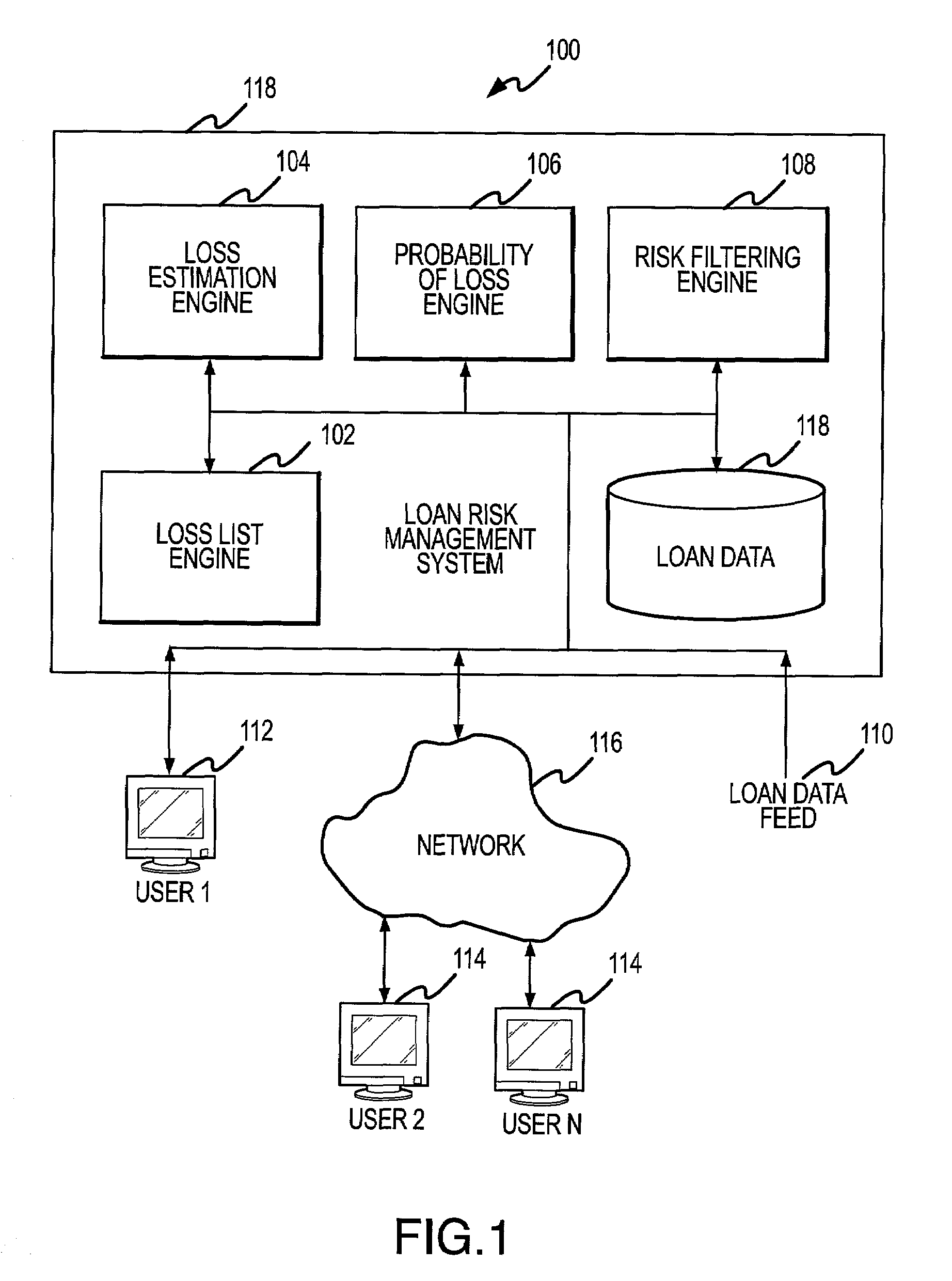

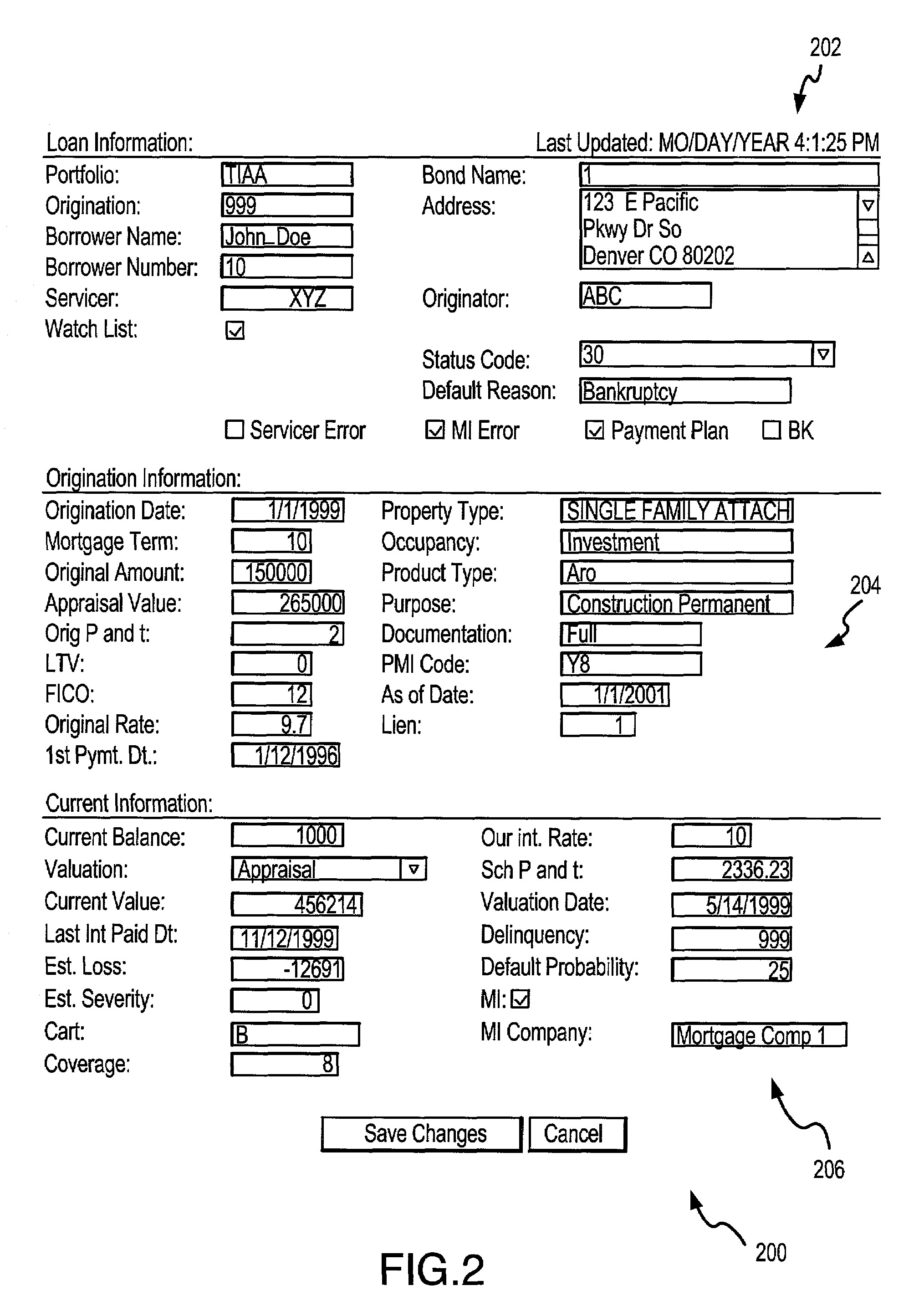

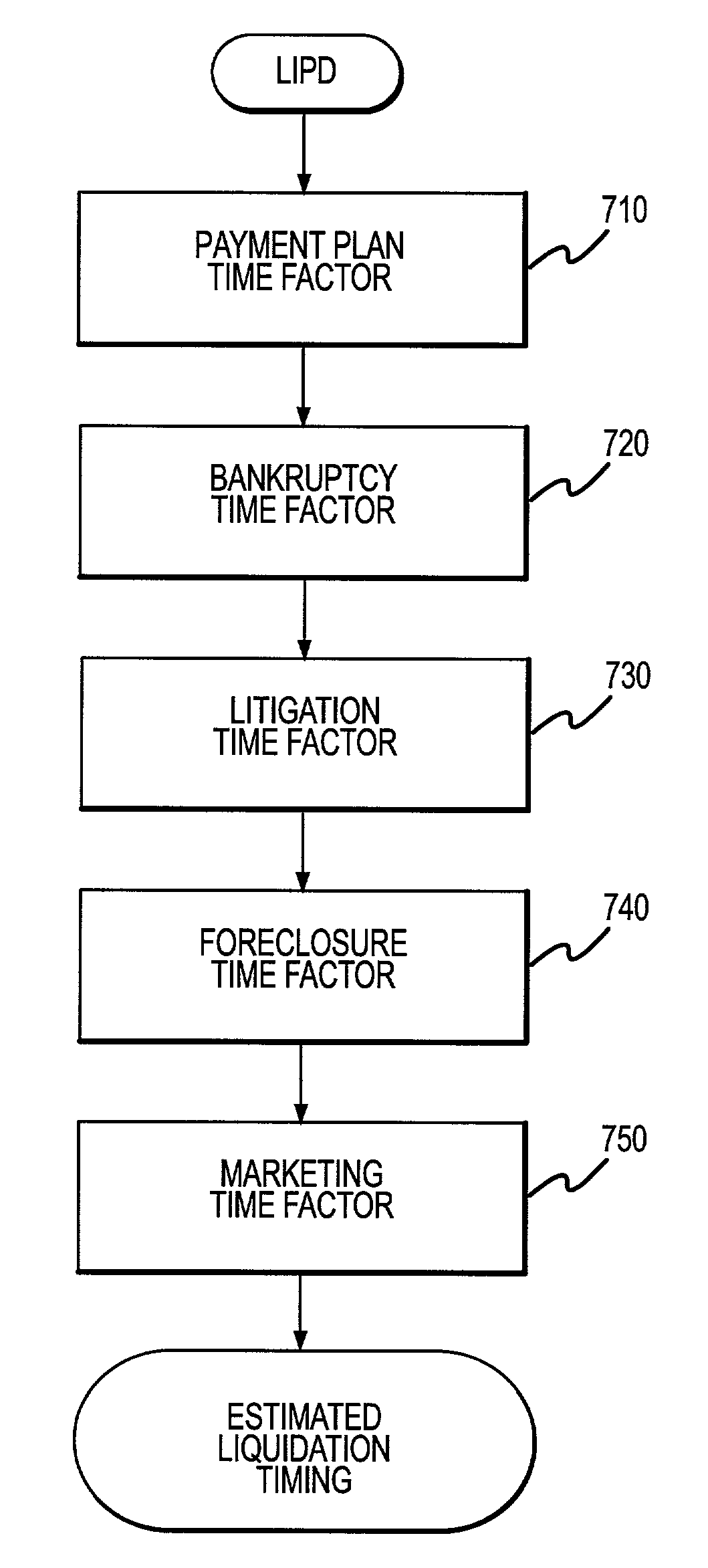

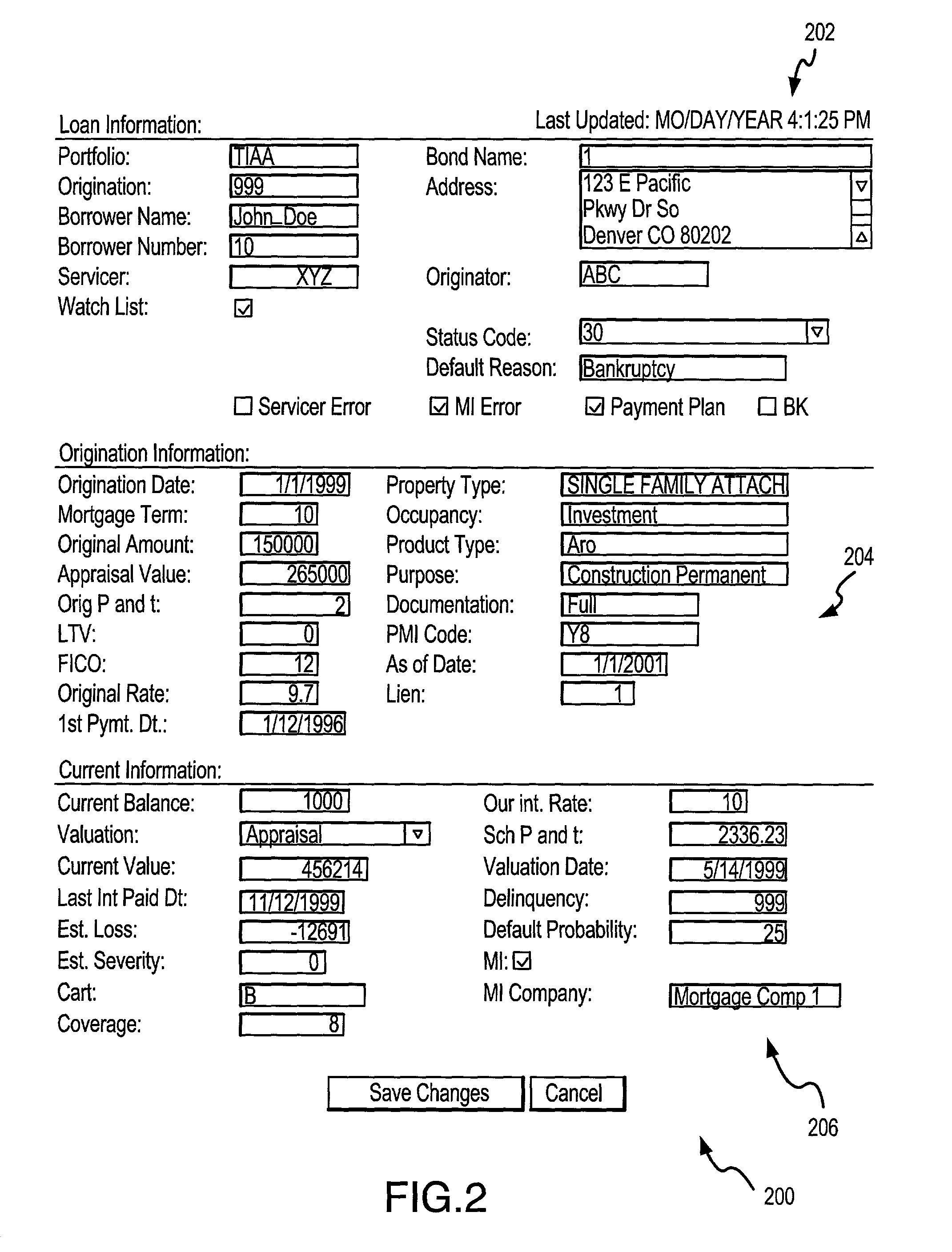

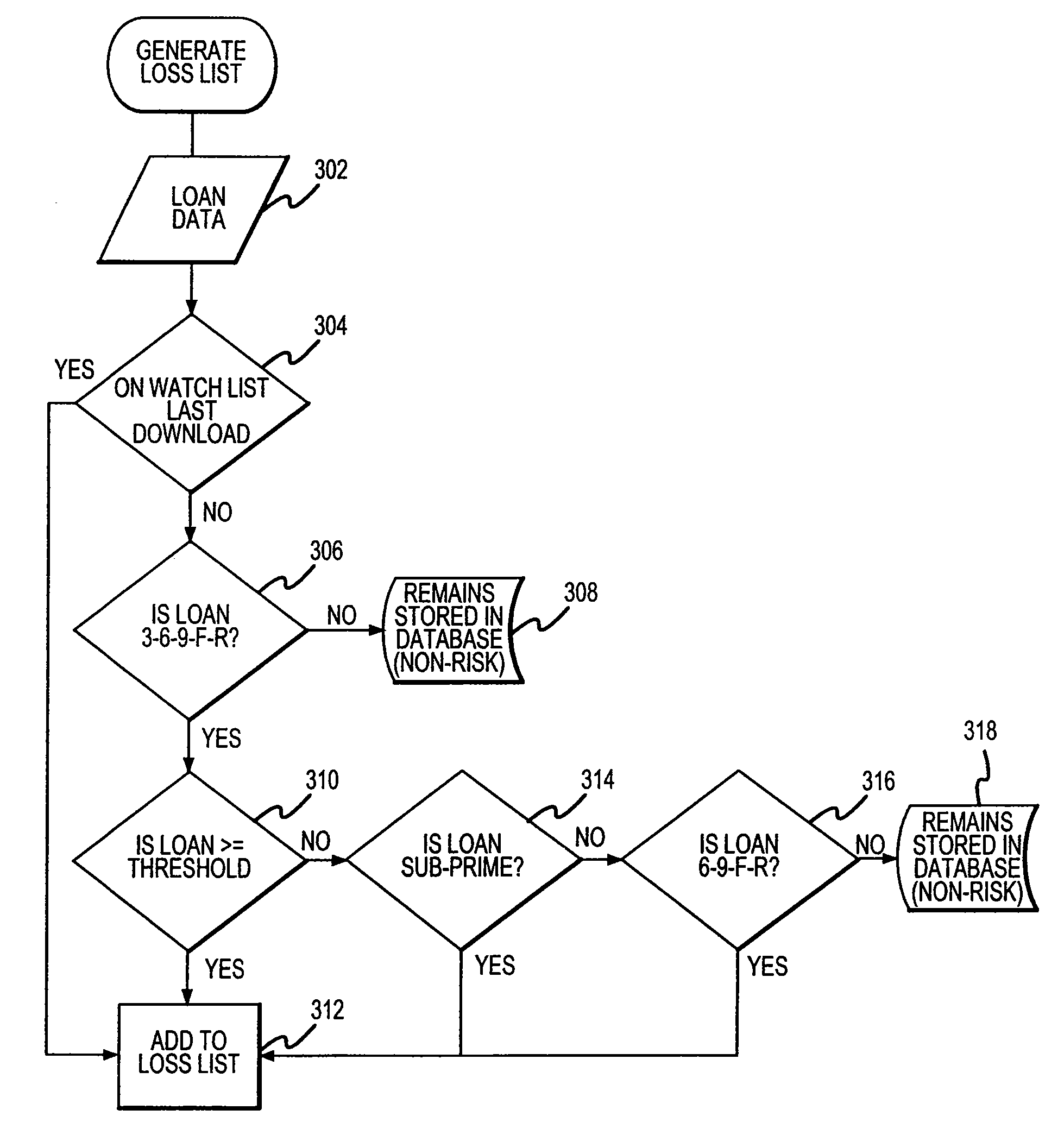

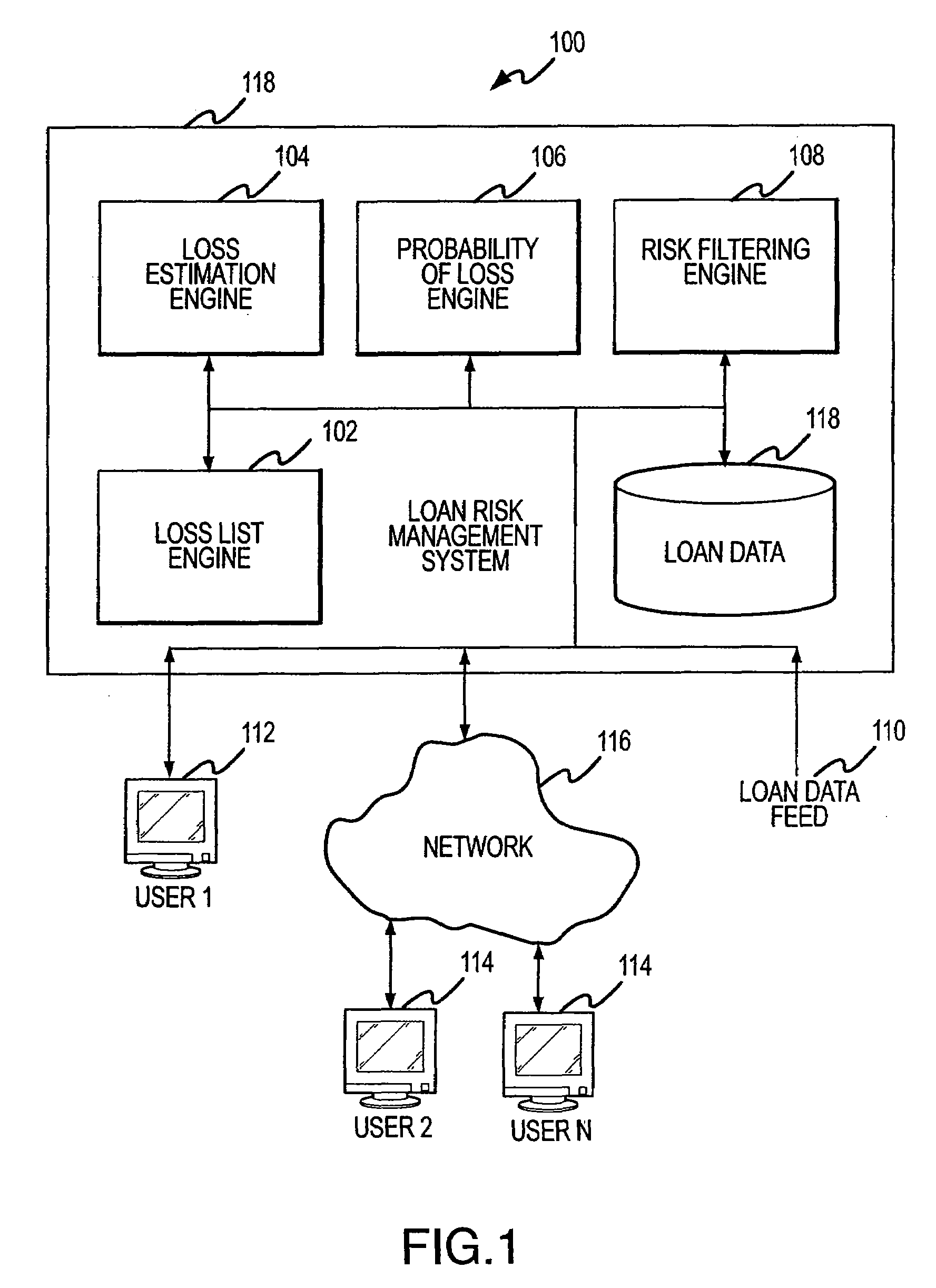

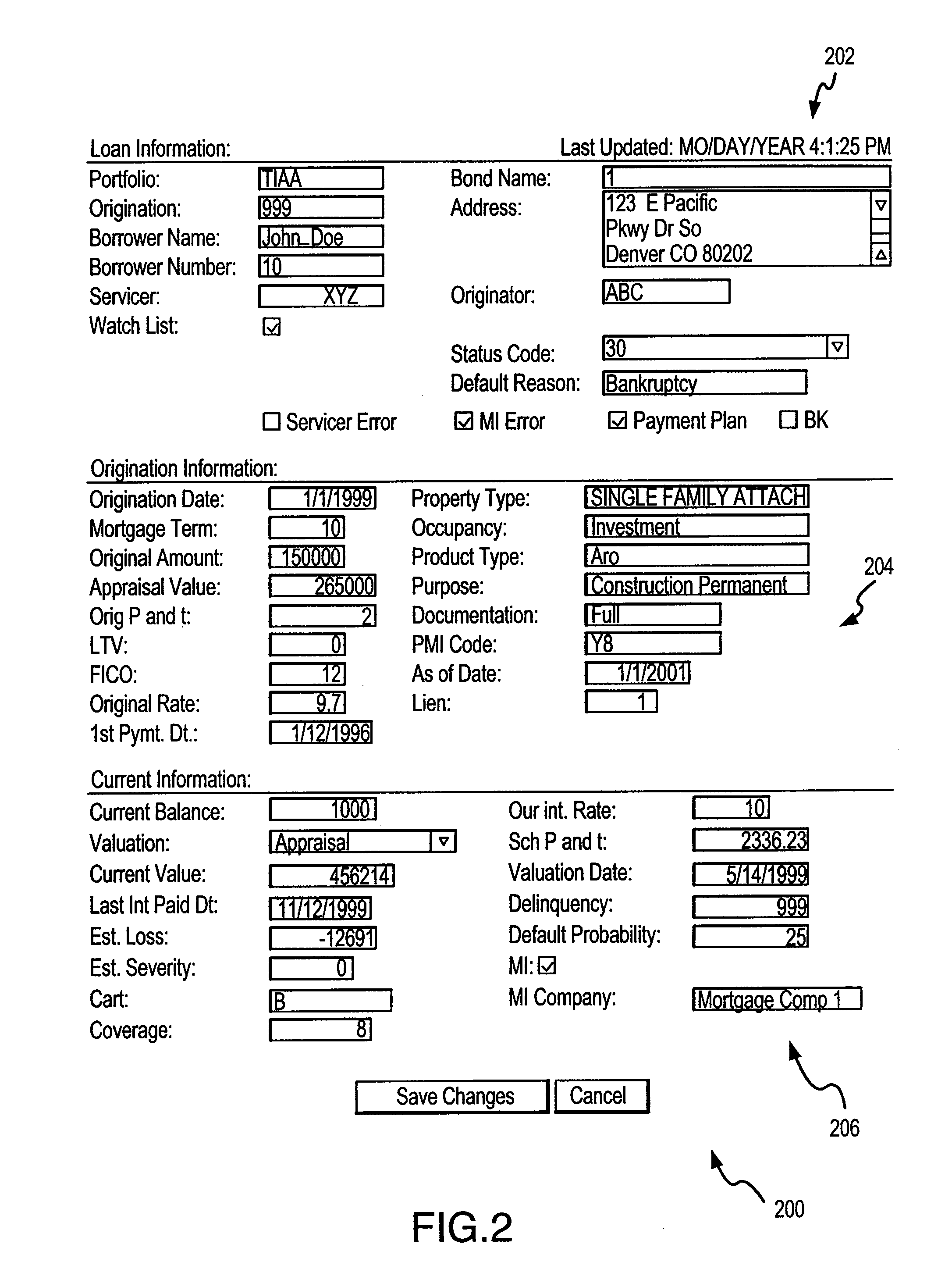

Credit risk managing loan pools

A system providing a comprehensive tool useful in credit risk managing a set of loans. The system includes a method for obtaining an estimated financial outcome, i.e., a gain or a loss, for a particular loan, and applying the estimated loss for to the set. The system also includes a method for obtaining a probability of a loss for a particular loan, and applying the probability of loss to the set. The system further includes the generation of a list of loans from the set of loans with a heightened risk of loss.

Owner:CLAYTON FIXED INCOME SERVICES

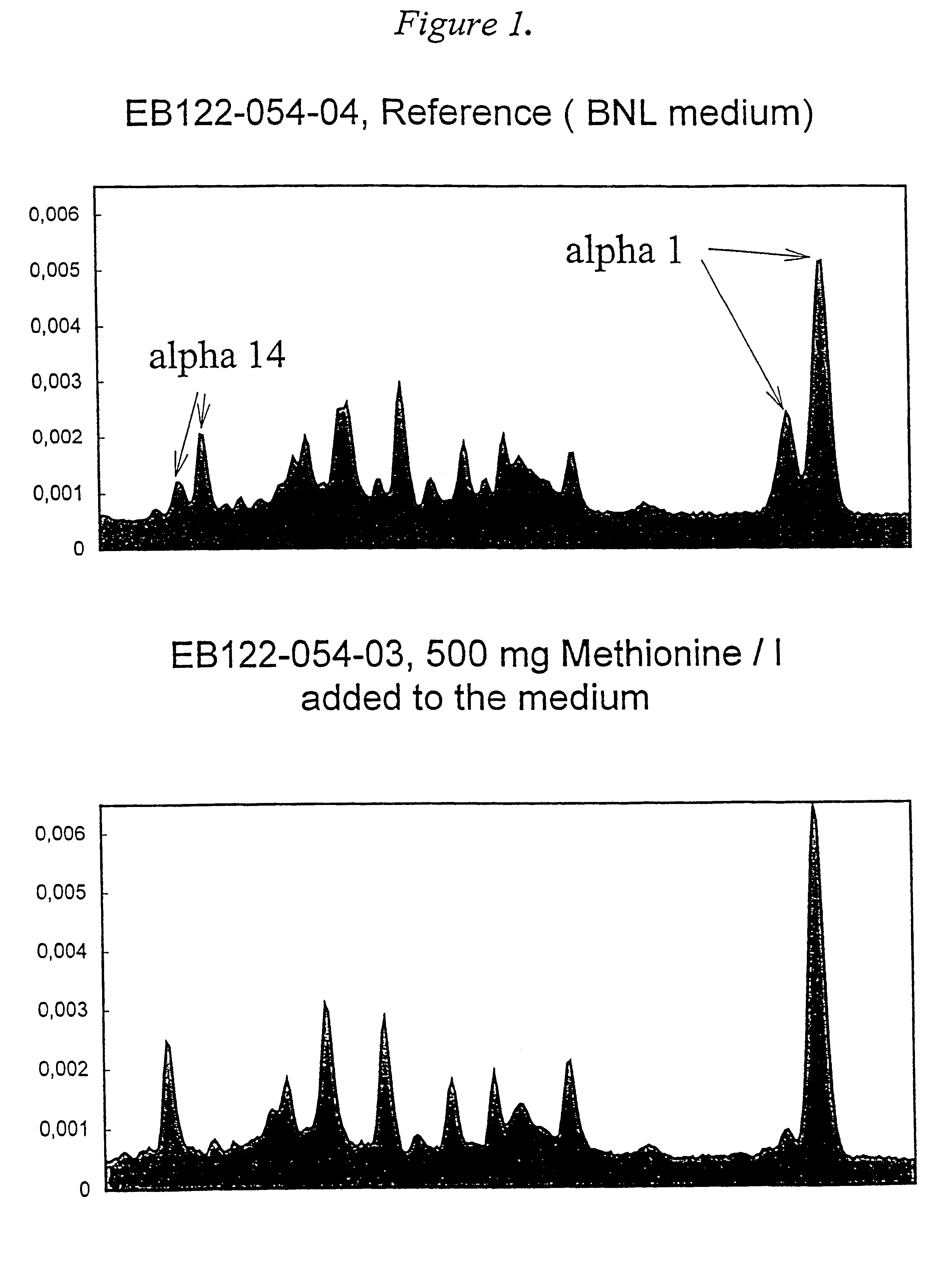

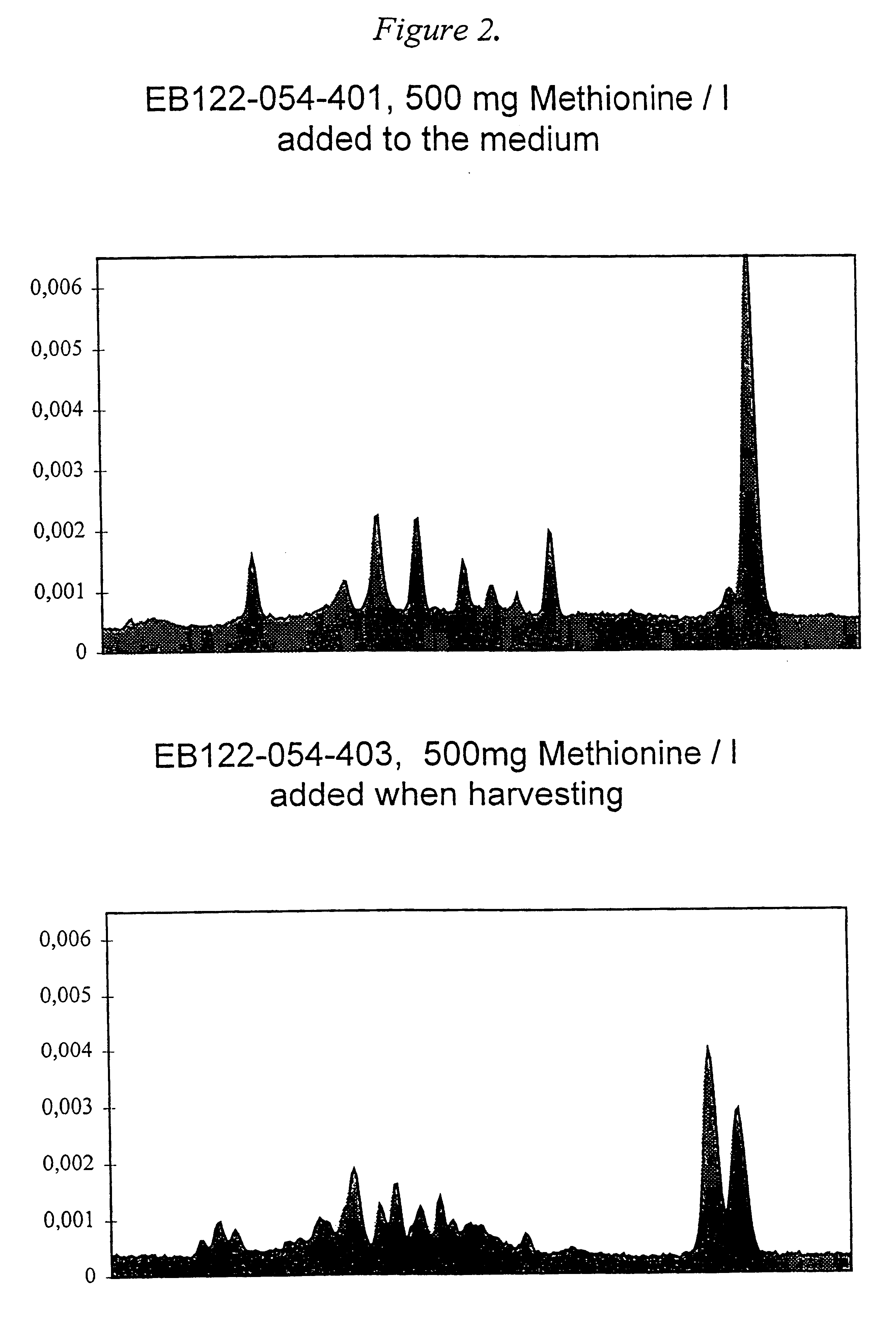

Methionine containing animal cell culture medium and its use

InactiveUS6309862B1Facilitates purification of desired productEasy to prepareCulture processCell culture mediaBiotechnologyWhite blood cell

A nutrient medium for protein producing cells, characterized in that said medium consists essentially of the following components: a physiological saline containing Ca2+, K+, Mg2+ and Na+, an energy source, a pH buffer and methionine in an amount of 0.015-2.0 g / liter, and optionally antibiotics. The invention further relates to use of the nutrient medium for cells and human leukocytes.

Owner:SWEDISH ORPHAN INT

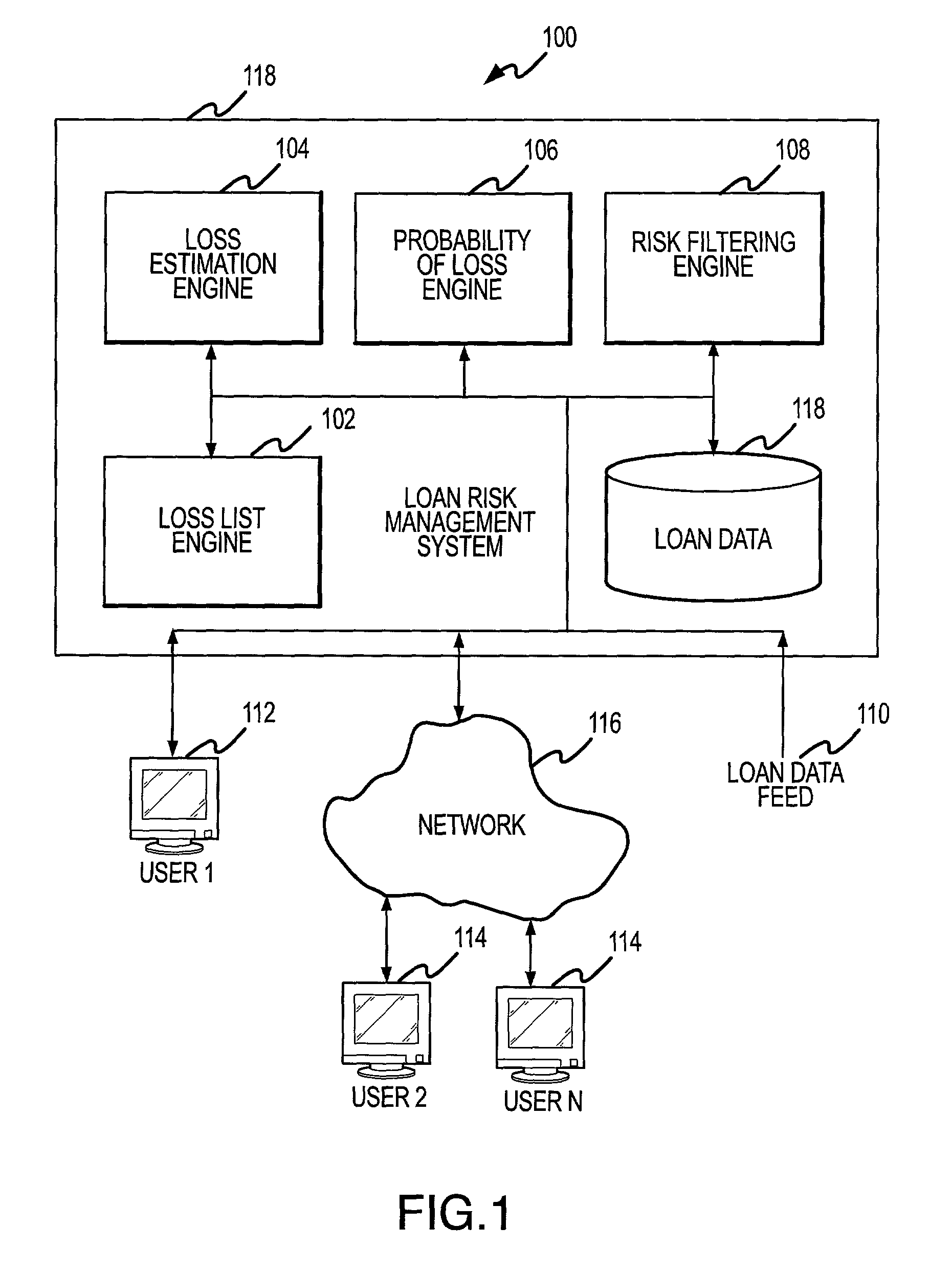

Analyzing investment data

A system and method for analyzing loan data to identify risk. In a database, loan data is stored with one or more associated characteristics. The system includes a risk filtering engine is in communication with the database so that a user may apply one or more risk filters to the loan data to identify particular loans with particular risk characteristics. The system further includes a loss estimation engine for providing an estimated loss for each loan, a probability of loss engine for determining a probability of loss for each loan, and a loss list engine for generating a list of loans with heightened risk of loss.

Owner:CLAYTON FIXED INCOME SERVICES

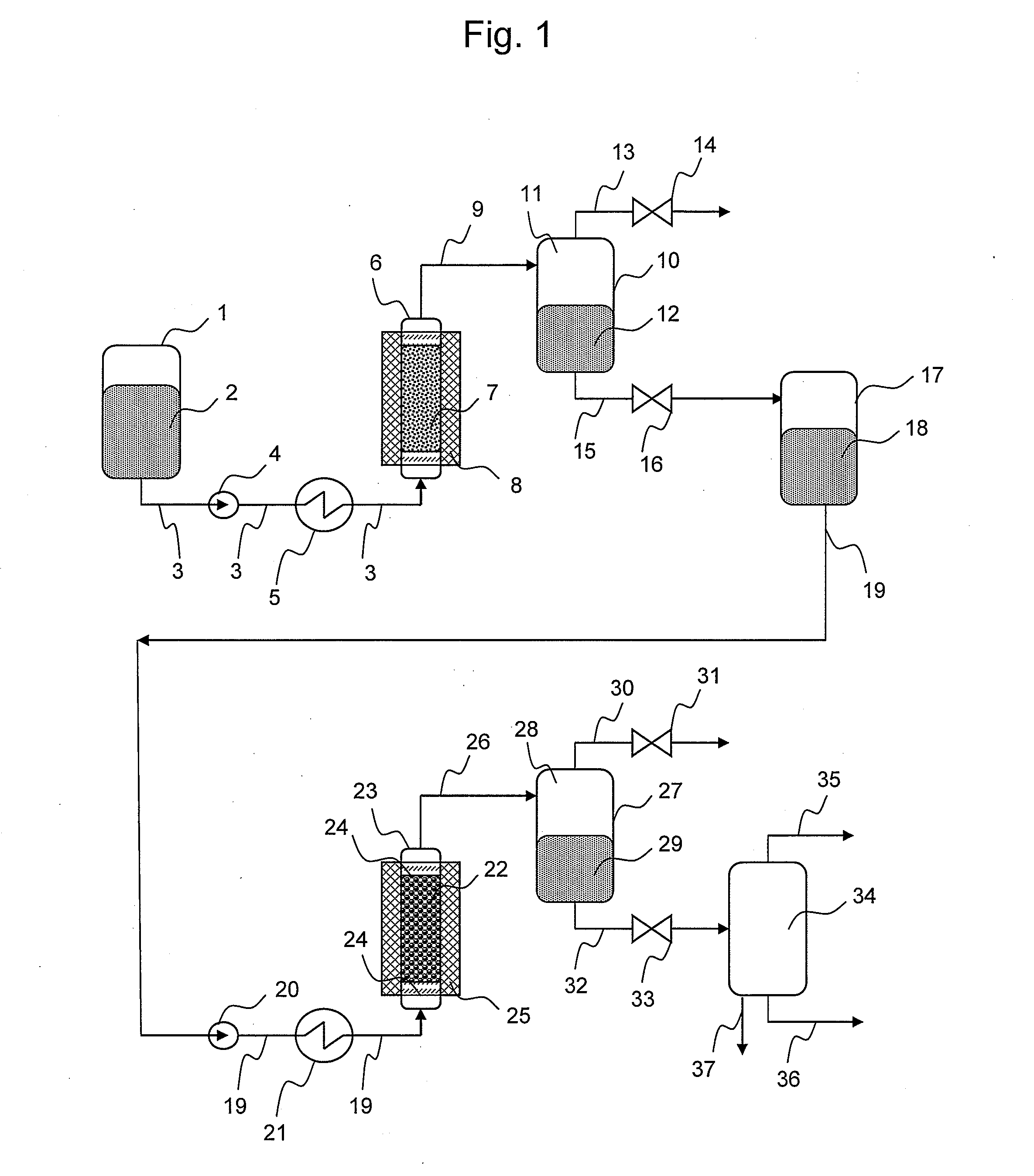

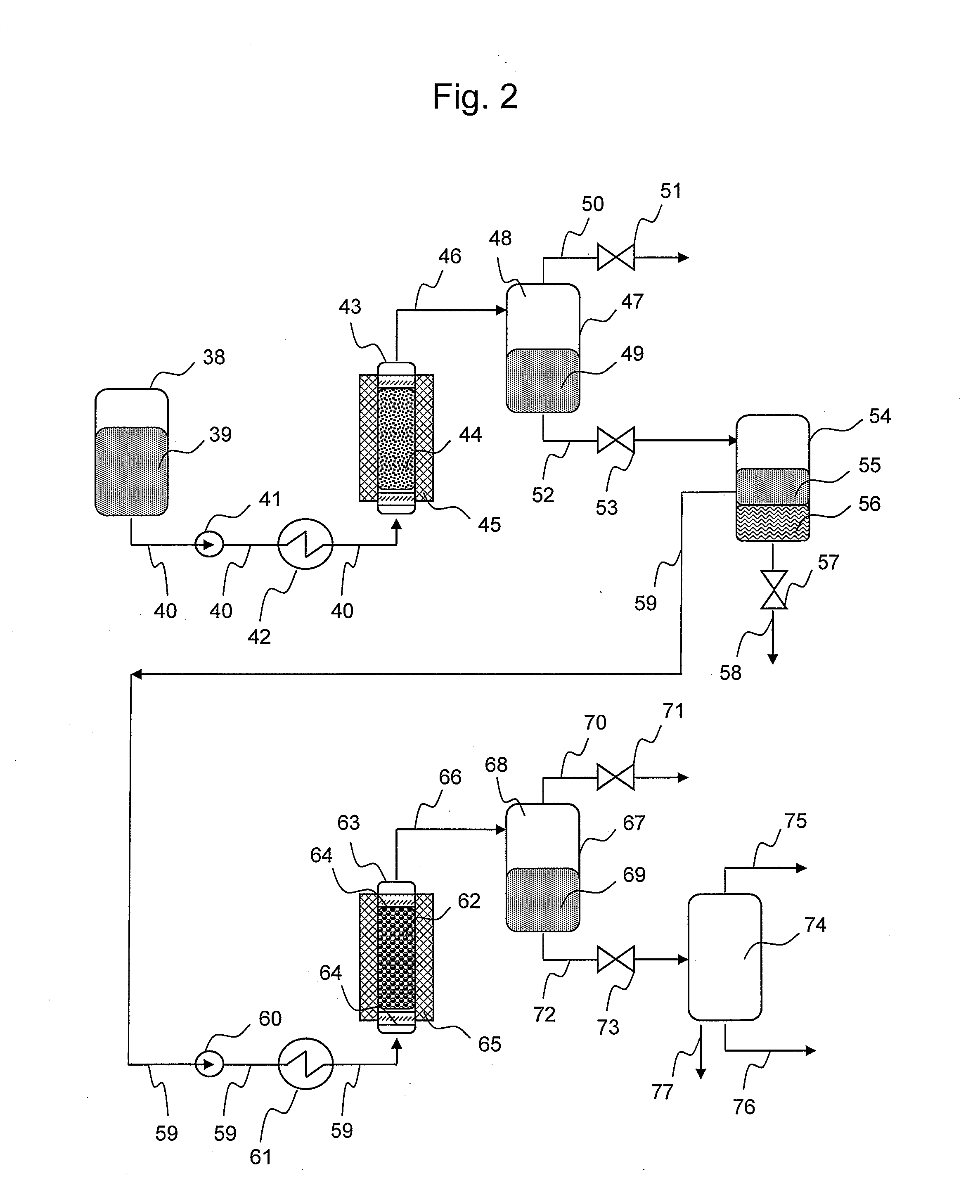

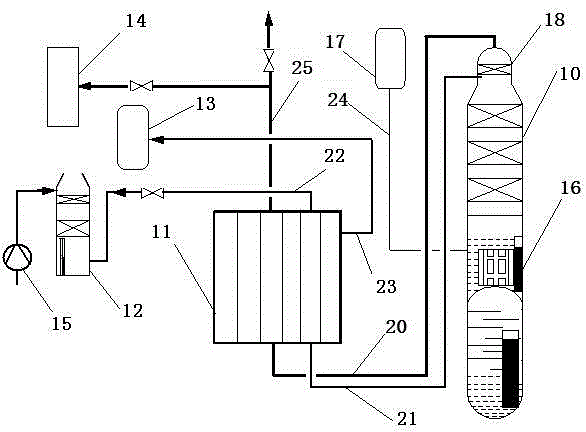

Method for producing water-insoluble liquefied fuel oil from biomass

InactiveUS20100312027A1Increase production capacityIncrease productionLiquid hydrocarbon mixture productionBio-feedstockCelluloseWater insoluble

A method for producing a water-insoluble liquefied fuel oil containing a hydrocarbon from biomass is provided, comprising converting an oxygen-containing compound in a liquefied fuel oil obtained after liquefaction to a hydrocarbon and converting a water-soluble organic substance contained in an aqueous phase to a hydrocarbon, thereby improving the yield of the water-insoluble liquefied fuel oil. The method for producing a water-insoluble liquefied fuel oil containing a hydrocarbon comprises the steps of: subjecting a mixture that contains biomass containing lignocellulose, an organic solvent, and water to liquefaction; simultaneously with or after liquefaction, causing a mixture of the liquefied fuel oil that contains the organic solvent and an aqueous phase that contains a water-soluble organic substance to come into contact with a dehydration catalyst under pressure and then subjecting the resultant to dehydration, or causing a mixture of the liquefied fuel oil that contains the organic solvent and an aqueous phase that contains a water-soluble organic substance to come into contact with hydrogen in the presence of a hydrogenation catalyst under pressure, and then subjecting the resultant to hydrogenation; and separating a water-insoluble liquefied fuel oil from the mixture after dehydration or hydrogenation.

Owner:TOYOTA JIDOSHA KK

Credit risk managing loan pools

InactiveUS7729983B1Increased riskMaintain productionFinancePayment architectureComputer scienceData science

A system providing a comprehensive tool useful in credit risk managing a set of loans. The system includes a method for obtaining an estimated financial outcome, i.e., a gain or a loss, for a particular loan, and applying the estimated loss for to the set. The system also includes a method for obtaining a probability of a loss for a particular loan, and applying the probability of loss to the set. The system further includes the generation of a list of loans from the set of loans with a heightened risk of loss.

Owner:CLAYTON FIXED INCOME SERVICES

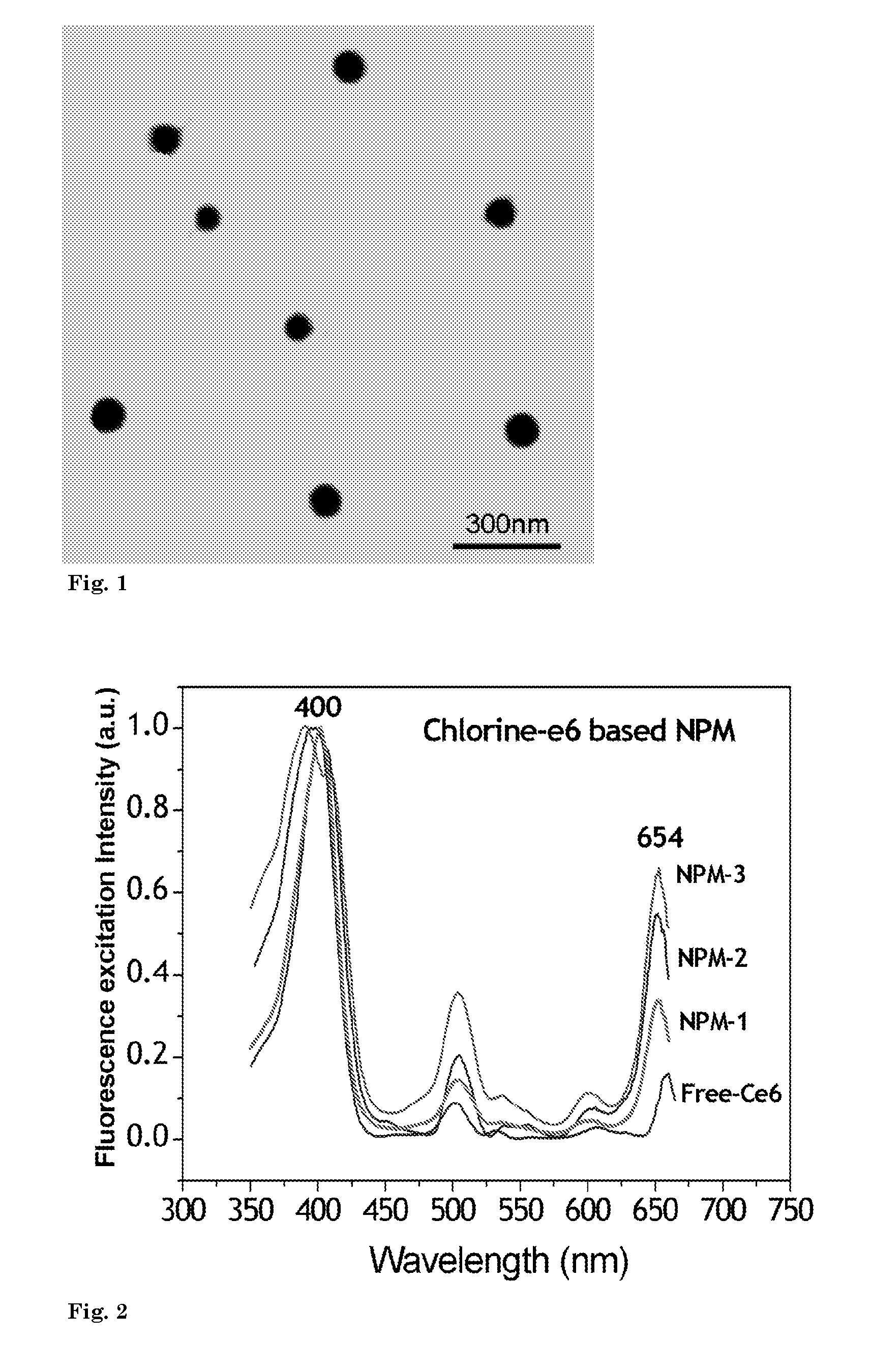

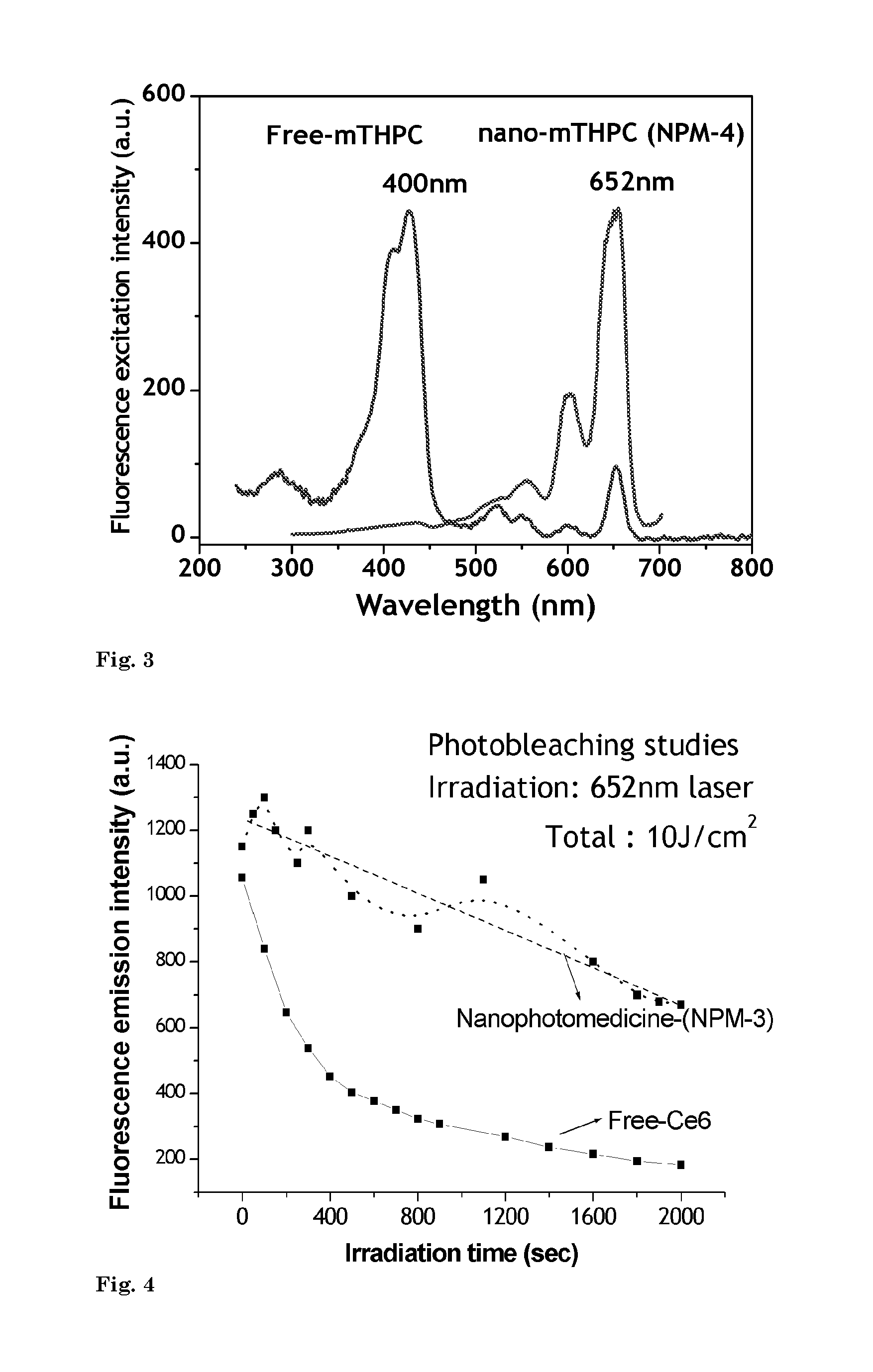

Targeted nano-photomedicines for photodynamic therapy of cancer

InactiveUS20120184495A1Good curative effectHigh tissue penetrationPowder deliveryBiocidePhotosensitizerCancer cell

The present invention relates to a photosensitizer-containing nanoparticle, comprising a photosensitizer covalently bonded throughout at least a part of said nanoparticle to the nanoparticle matrix material and incorporated therein in a quasi-aggregated state. The present invention further relates to methods for producing the invention nanoparticles, and to methods of killing cancer cells by PDT treatment using the said nanoparticles.

Owner:ERASMUS UNIV MEDICAL CENT ROTTERDAM ERASMUS MC +1

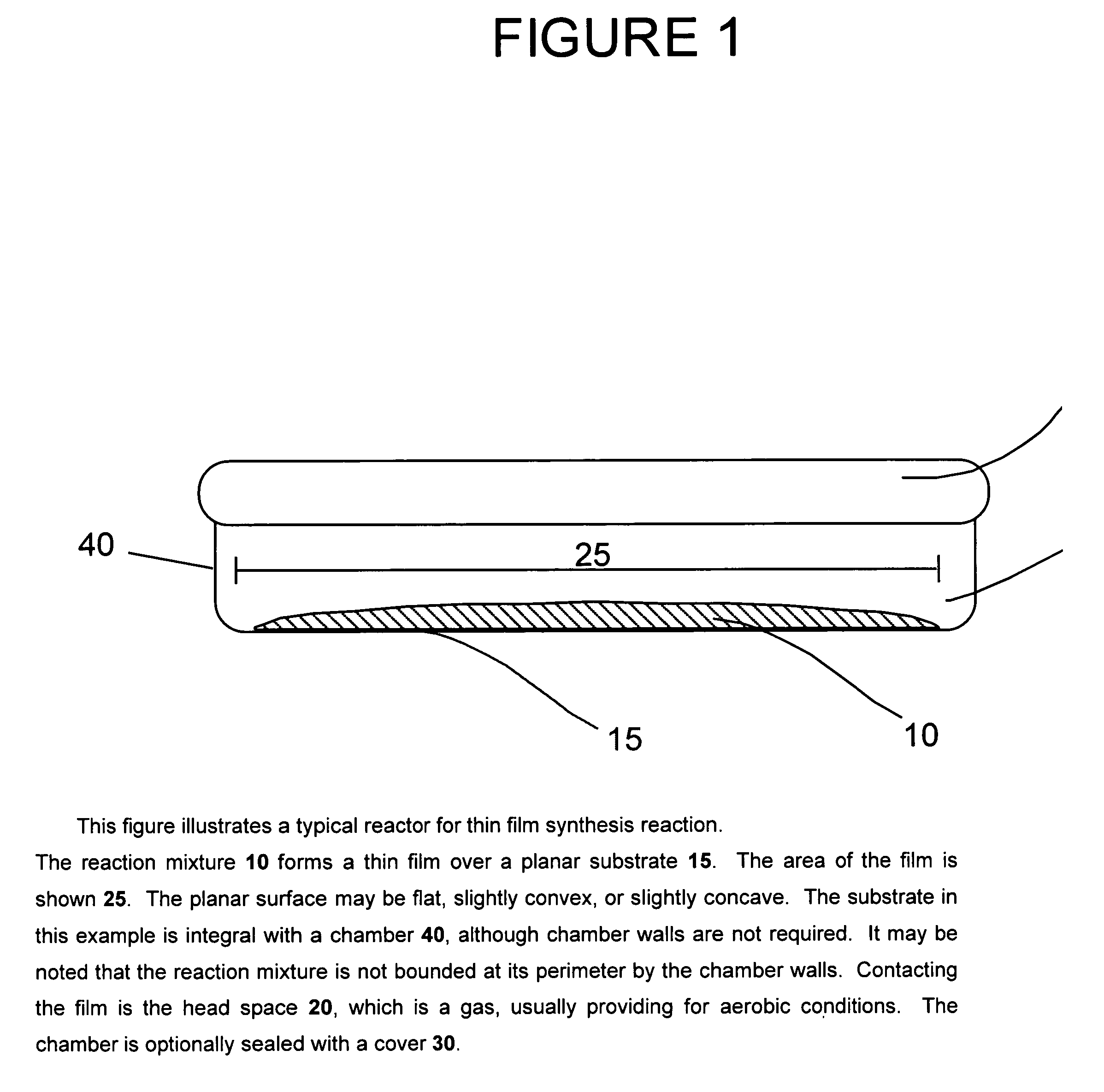

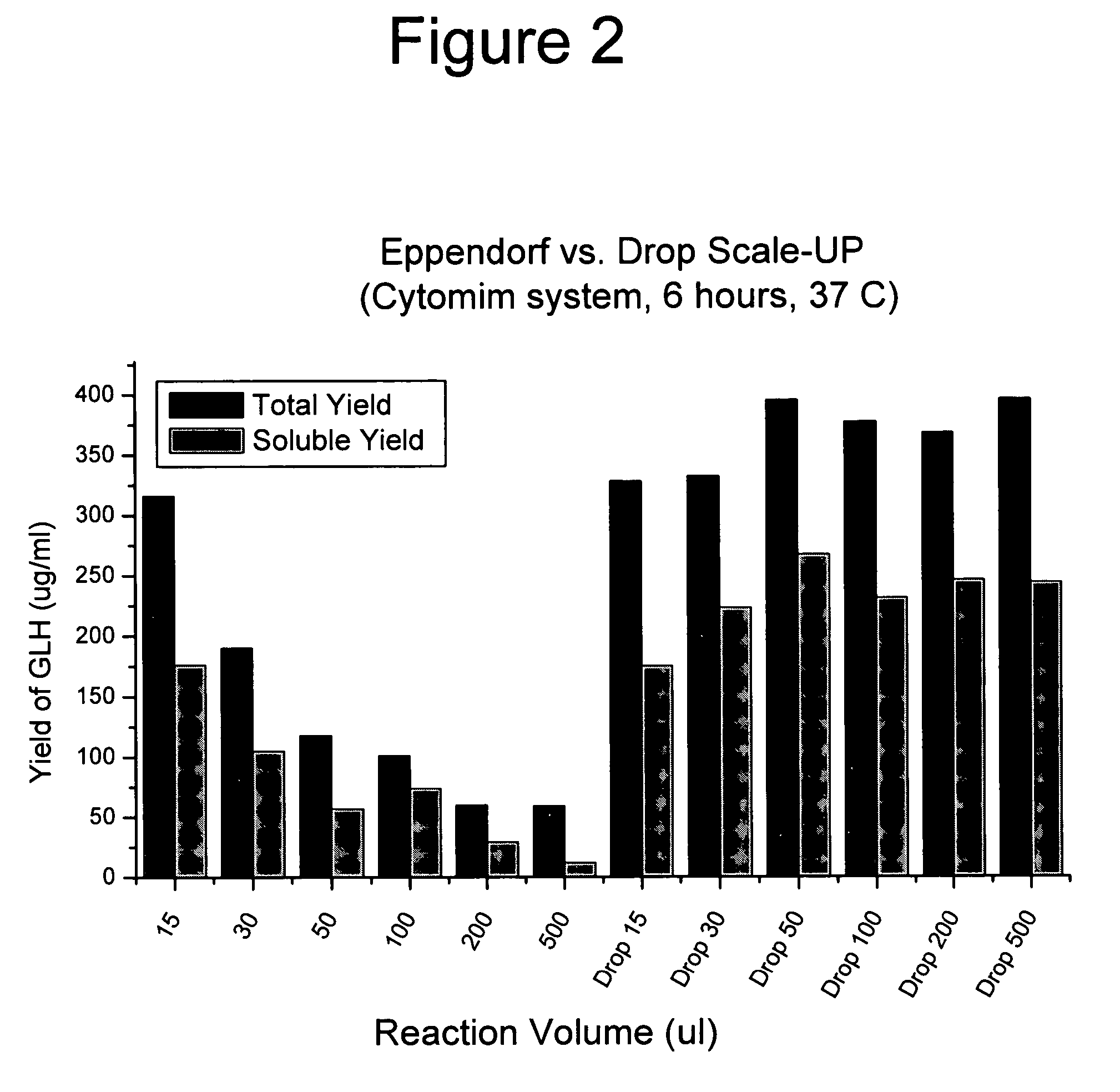

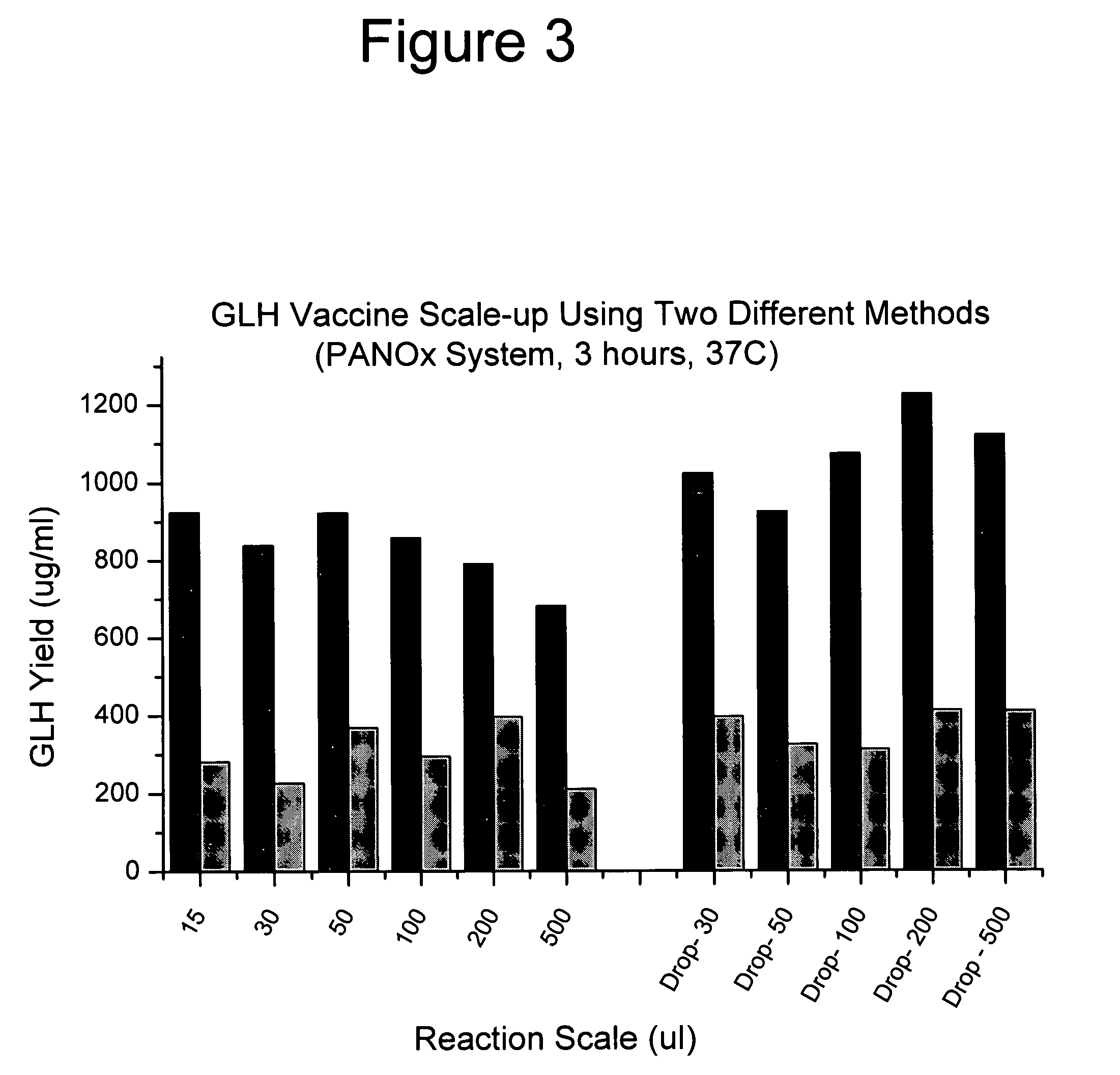

Methods of decoupling reaction scale and protein synthesis yield in batch mode

ActiveUS7341852B2Large specific surface areaMaintain productionFermentationVector-based foreign material introductionBiological macromoleculeHigh surface area

Biological macromolecules are synthesized in vitro in a thin film that provides for high surface area / volume ratio, allowing improved yield in scaled up reactions.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

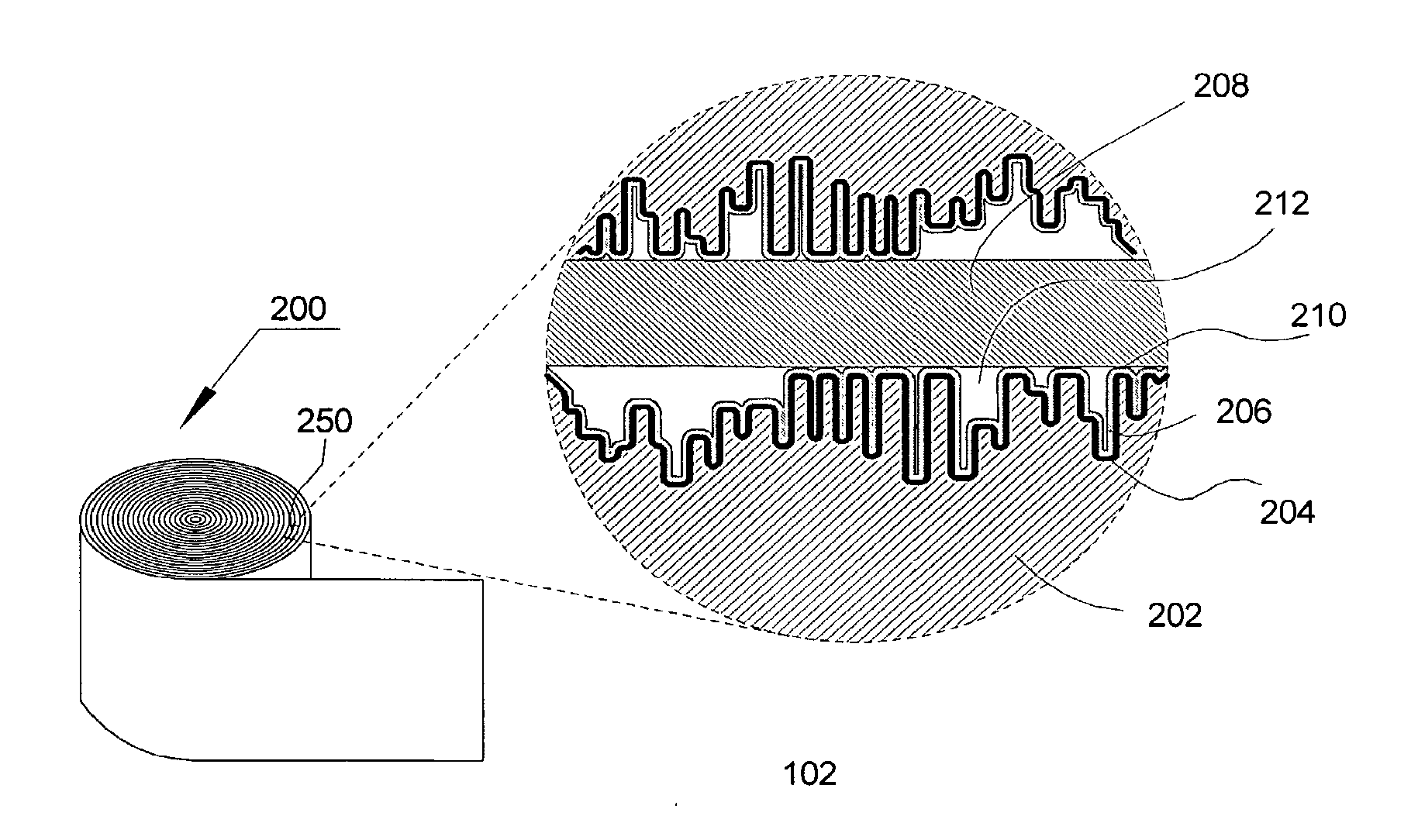

Capacitors with high energy storage density and low esr

InactiveUS20110310526A1Unique pinhole free and low stress propertyHigh yieldElectrolytic capacitorsFixed capacitor dielectricCapacitanceHigh energy

Electrostatic capacitors with high capacitance density and high-energy storage are implemented over conventional electrolytic capacitor anode substrates using highly conformal contact layers deposited by atomic layer deposition. Capacitor films that are suitable for energy storage, electrical and electronics circuits, and for integration onto PC boards endure long lifetime and high-temperature operation range.

Owner:SUNDEW TECH

Crystallization of Anti-cd20 antibodies

InactiveUS20110020322A1Eliminate the problemLow costAntibody ingredientsImmunoglobulinsAntiendomysial antibodiesBiochemistry

The present invention relates generally to crystalline forms of anti-CD20 antibodies and purification of anti-CD20 antibodies involving crystallization.

Owner:GENENTECH INC

Fluid catalytic cracking catalyst having desulfurizing functions, process for production of the same, and process for production of low-sulfur catalytically cracked gasoline with the catalyst

InactiveUS20090230023A1Efficient productionMaximum functionCatalytic crackingMolecular sieve catalystsClay mineralsReverse osmosis

The present invention 1, 2 or 3 provides a desulfurization function-added FCC catalyst which can efficiently reduce the sulfur content of FCC gasoline while maintaining the yield of FCC gasoline in a process of producing FCC gasoline by cracking of heavy oil. The catalyst has vanadium supported on a carrier comprising (a) an alumina-coated zeolite and (b) a porous inorganic oxide except zeolite and / or a clay mineral, wherein the supported vanadium amount is from 500 to 20000 ppm by mass in terms of vanadium metal and the acid amount is from 20 to 450 μmol / g and the macropore surface area is from 30 to 150 m2 / g; or the catalyst has vanadium supported on a carrier containing from 5 to 40% by mass of (a) an alumina-coated zeolite and from 30 to 70% by mass of (b) an alumina, wherein the vanadium concentration ratio before and after grinding the catalyst is at least 2; or the catalyst has at least vanadium and manganese and / or phosphorus supported on a porous inorganic oxide-containing carrier, wherein the supported vanadium amount is from 500 to 20000 ppm by mass in terms of vanadium metal, vanadium and manganese and / or phosphorus form a complex ion in the supporting solution for use in supporting vanadium and manganese and / or phosphorus, and the permeability of the complex ion through a reverse osmosis membrane is at most 25% relative to the permeability of vanadium through the reverse osmosis membrane.

Owner:IDEMITSU KOSAN CO LTD +1

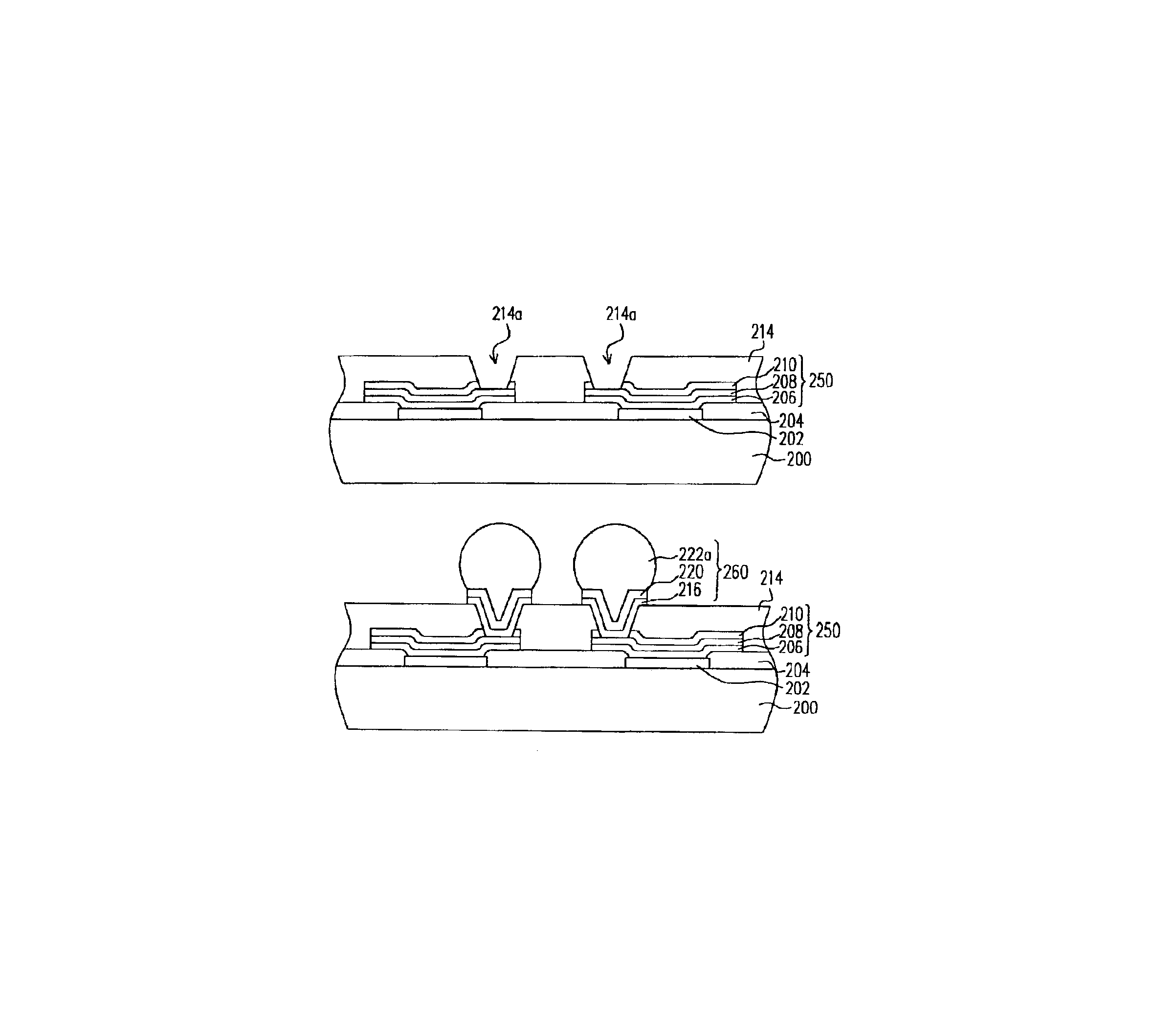

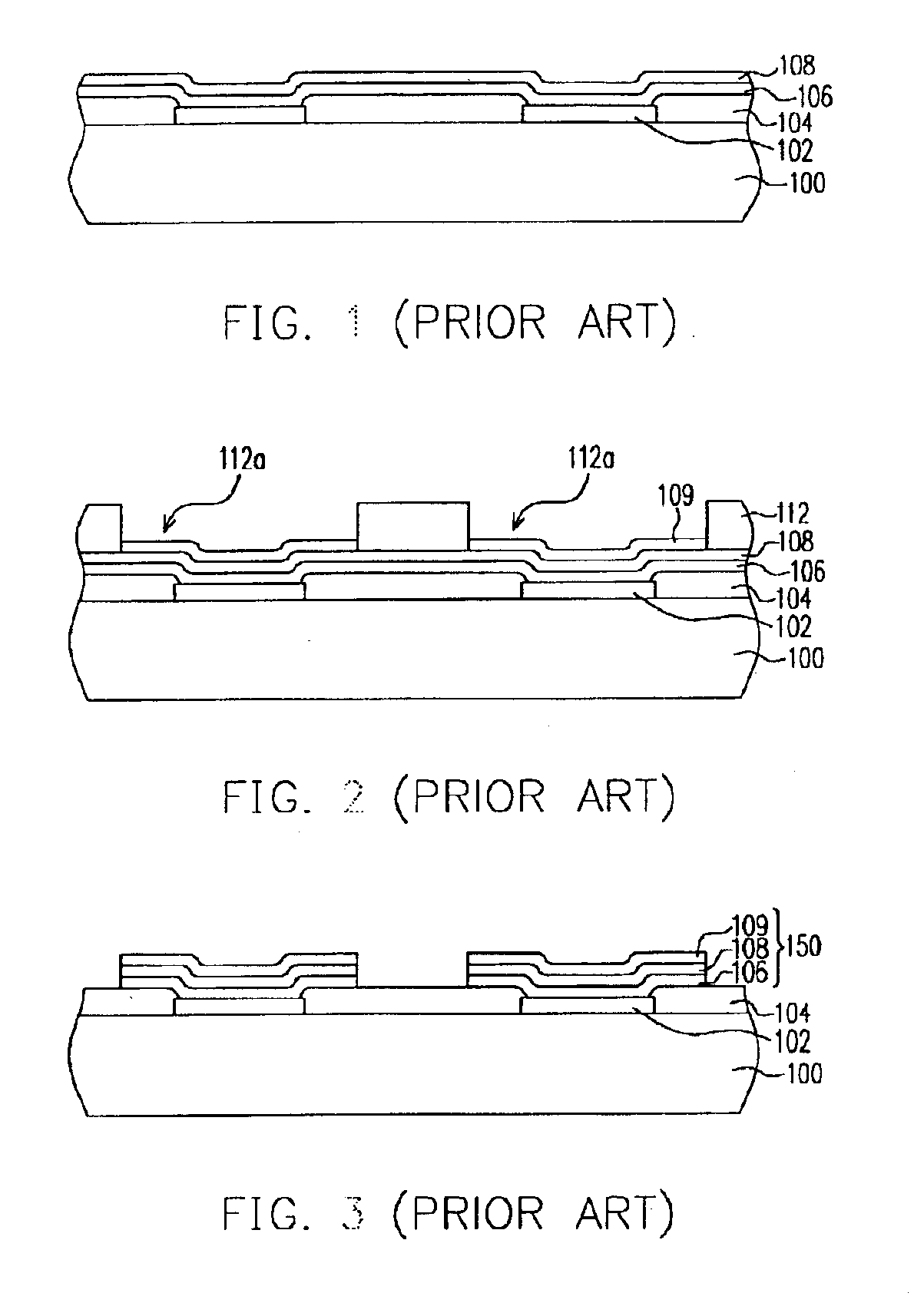

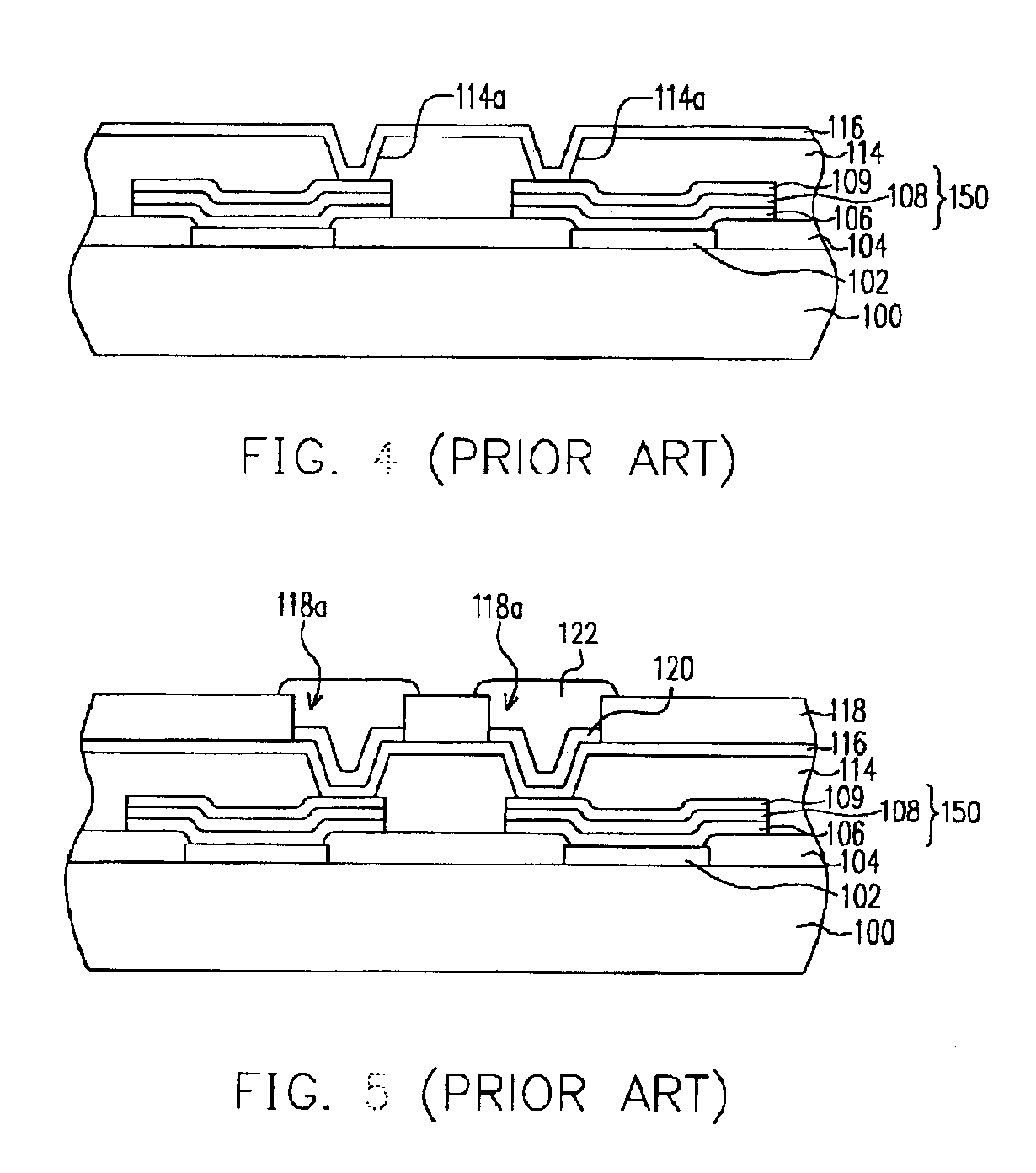

Redistribution process

InactiveUS6867122B2Maintain productionPrevent peelingSolid-state devicesPhotomechanical apparatusTitaniumCopper

A redistribution process is described. A wafer is provided, wherein a first titanium layer, a first copper layer and a second titanium are sequentially formed over the surface of the wafer. The second titanium layer, the first copper layer and the first titanium layer are then defined to form a patterned trace layer. A patterned benzocyclobutene layer is then formed to expose the second titanium layer. The exposed second titanium layer is further removed to expose the first copper layer. Thereafter, a plurality of contacts is formed over the patterned benzocyclobutene layer and to connect with the first copper layer. Further, the wafer comprises a plurality of bonding pads, wherein each bonding pad is connected with each contact through the patterned trace layer.

Owner:ADVANCED SEMICON ENG INC

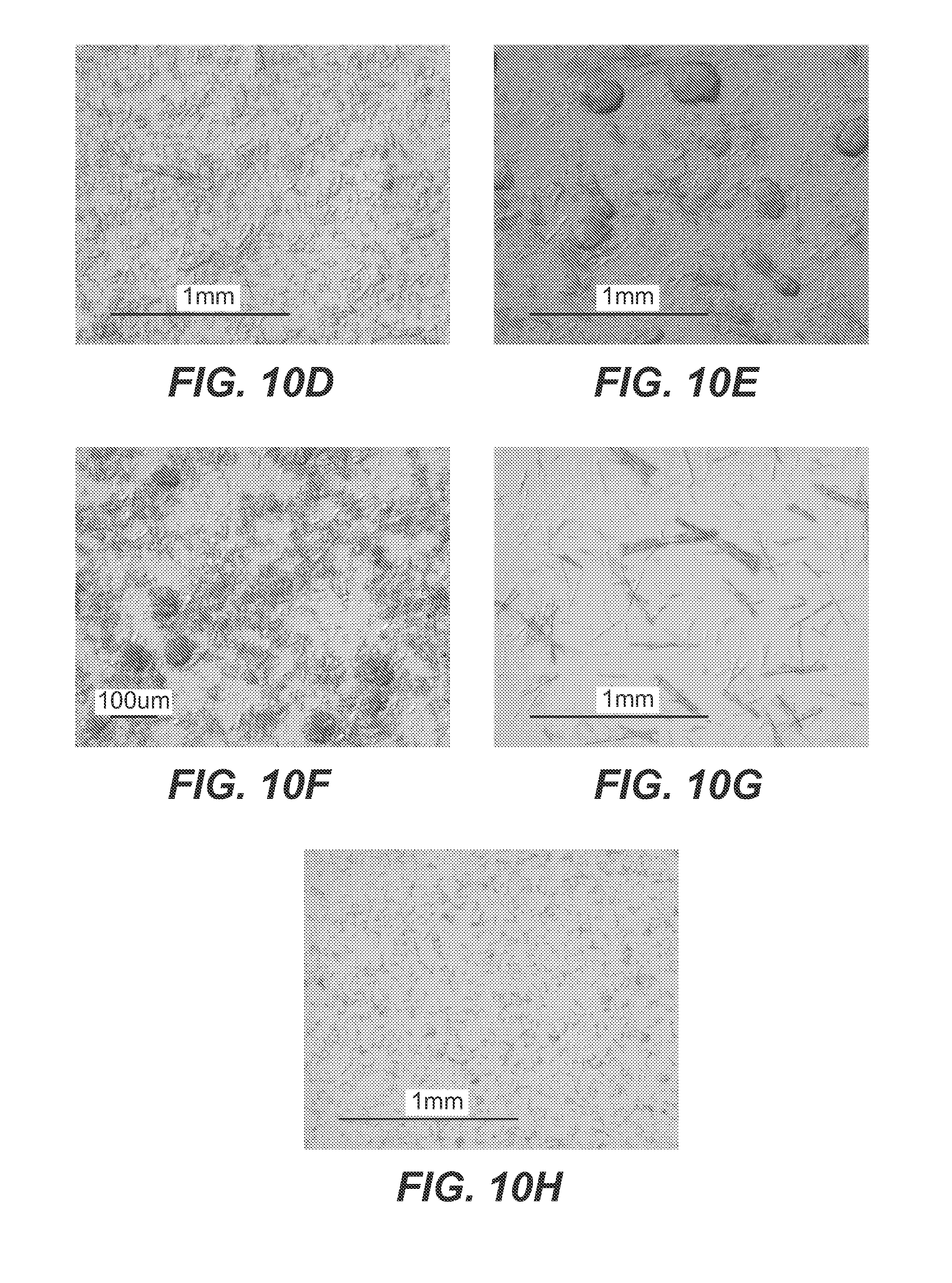

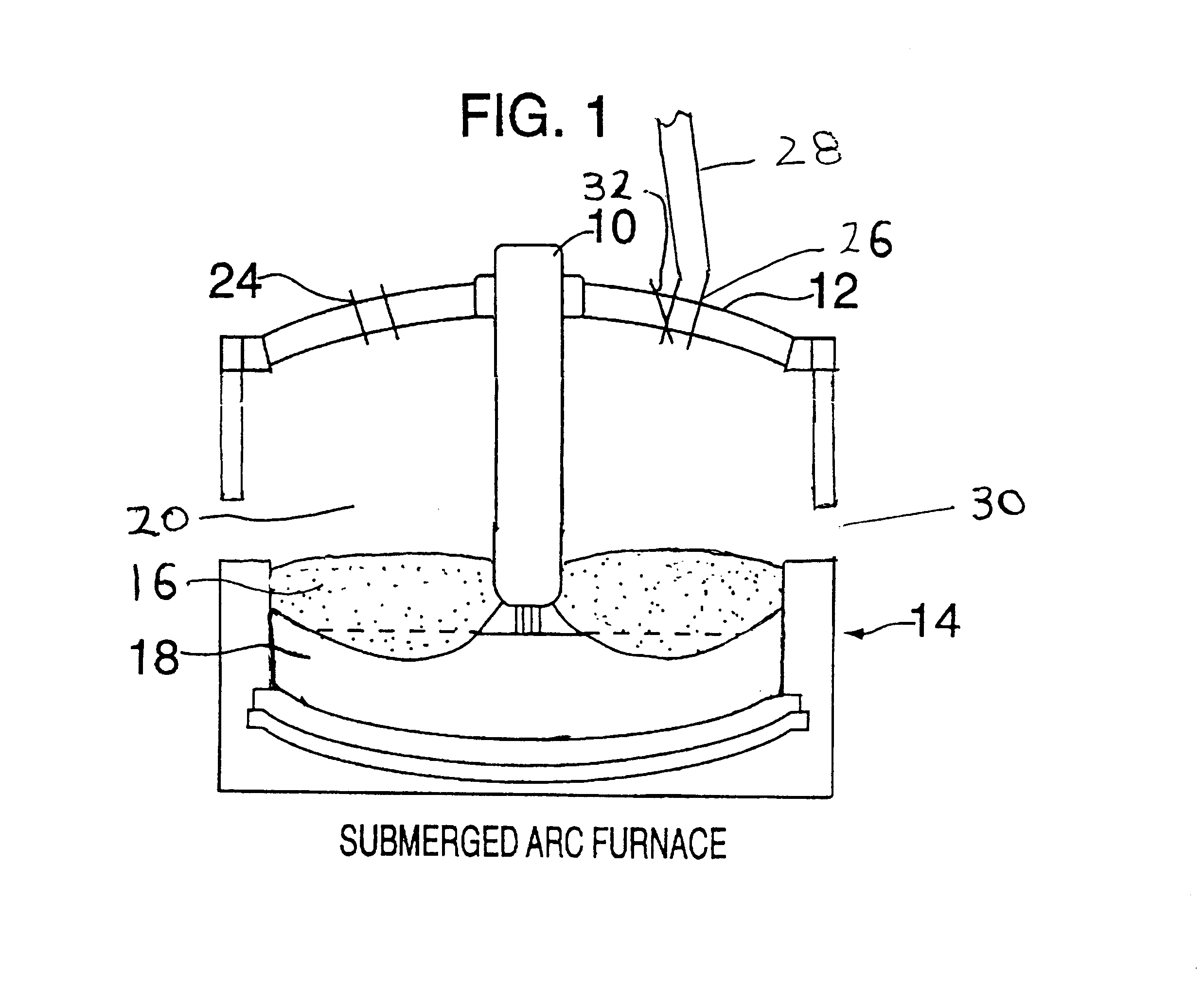

Method for production of white microsilica

InactiveUS6696035B2Improve reflectivityMaintain productionMaterial nanotechnologySilicaFerrosiliconSilicon dioxide

The present invention relates to a method for producing microsilica having a reflectivity between 65 and 90% in a smelting furnace for production of ferrosilicon or silicon by using a charge comprising an SiO2 source and a solid carbonaceous reduction agent, where microsilica is recovered from the off-gases from the smelting furnace, wherein the solid reduction agent supplied to the furnace contains an amount of volatile matters of less than 1.25 kg per kg produced microsilica and that the temperature in the gas atmosphere in the furnace above the charge is kept above 500° C.

Owner:ELKEM

Method for producing acrylonitrile, catalyst for use therein and method for preparing the same

InactiveUS6723869B1High catalytic efficiencyEffective maintenanceOrganic compound preparationPreparation by hydrocarbon ammoxidationIndiumCerium

For the production of acrylonitrile by ammoxidation of propylene, there is provided a catalyst capable of giving a high yield for a long period of time. In producing acrylonitrile by ammoxidation of propylene, there is used a metal oxide as a catalyst, which metal oxide contains iron, antimony, molybdenum, bismuth, potassium, an F element, a G element, an H element and silica as essential components in a specific composition ratio, and in which metal oxide iron antimonate exists as a crystal phase, provided that the F element is at least one element selected from the group consisting of magnesium, calcium, strontium, barium, manganese, cobalt, nickel, copper, silver, zinc and cadmium, the G element is at least one element selected from the group consisting of chromium, aluminum, gallium and indium, and the H element is at least one element selected from the group consisting of yttrium, lanthanum, cerium, praseodymium, neodymium and samarium.

Owner:MITSUBISHI CHEM CORP

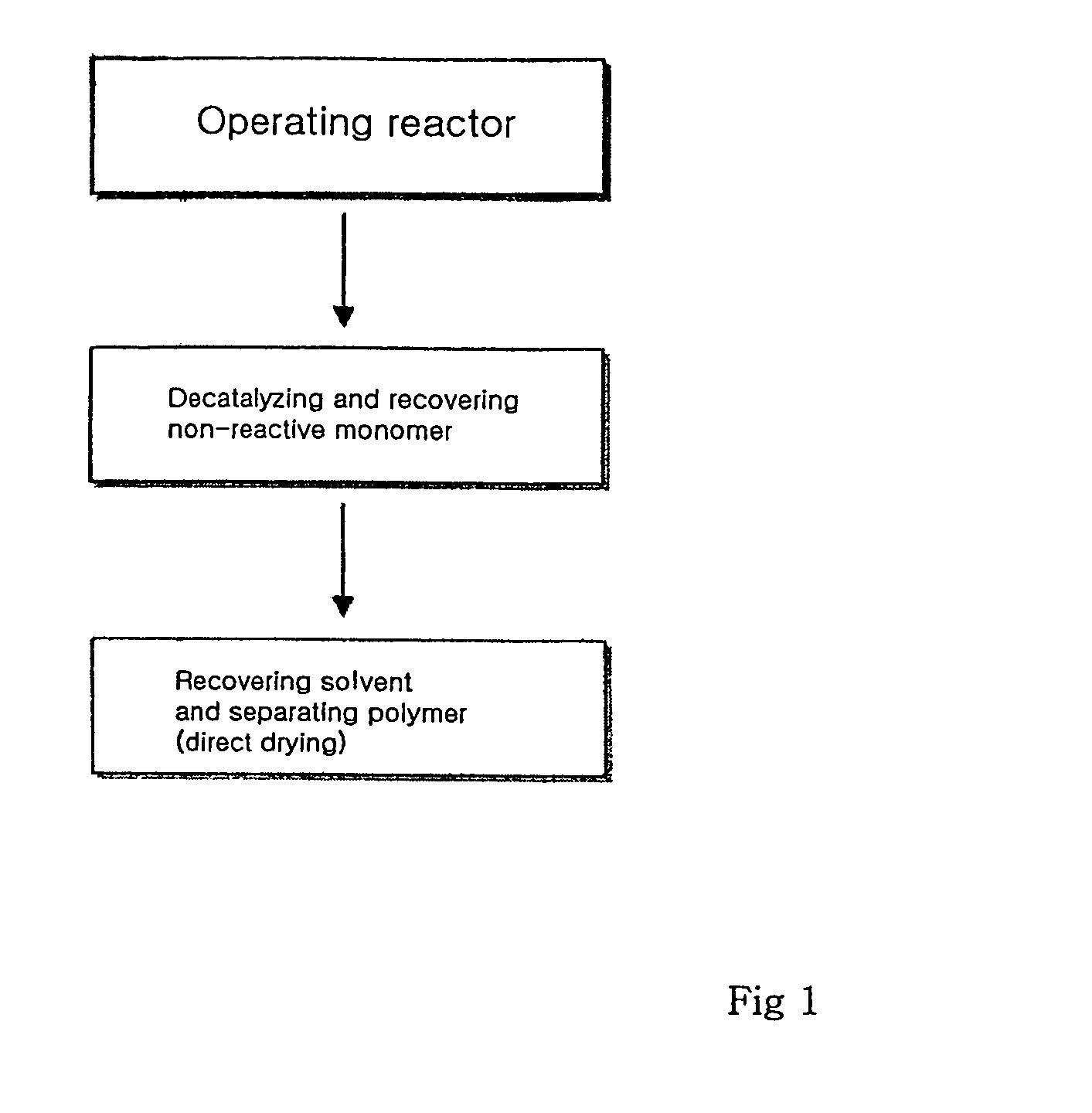

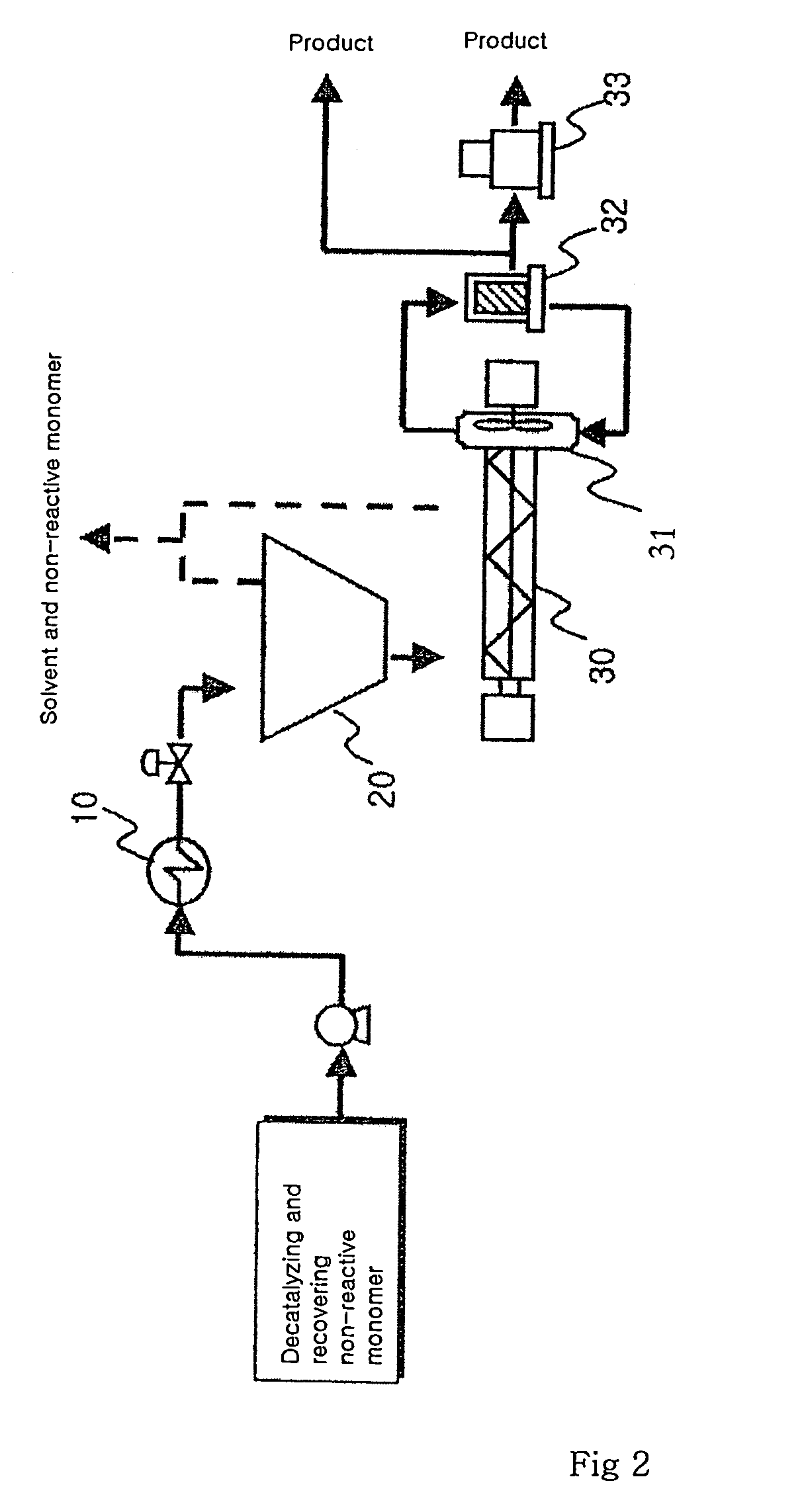

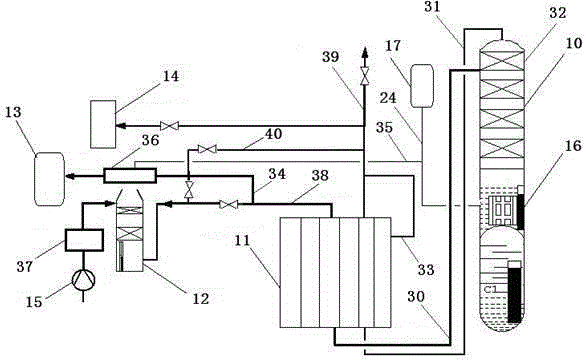

Methods of preparing EP(D)M elastomer, of controlling yield thereof, and of recovering the same

Disclosed herein is a method of preparing an EP(D)M elastomer, which includes pre-cooling a reactive solvent to −80 to −100° C.; and polymerizing ethylene, at least one higher α-olefin having 3 to 18 carbons, and selectively, at least one conjugated or non-conjugated diene having 5 to 15 carbons, in the presence of the reactive solvent. According to the method of the current invention, the yield of the EP(D)M elastomer is drastically increased even though a conventional preparation device is used unchanged. Further, methods of controlling the yield of the EP(D)M elastomer and of recovering the EP(D)M elastomer are provided.

Owner:KUMHO POLYCHEM

Method for improving nitrogen yield of air separation device

InactiveCN104949471AMaintain productionMaintain puritySolidificationLiquefactionMolecular sieveNitrogen

The invention discloses a method for improving the nitrogen yield of an air separation device. The method includes the steps that according to required product nitrogen increasing amount, rectification packing or the plate number needed when a certain amount of waste nitrogen is rectified into pure nitrogen is calculated; the rectification packing or the plate number of an upper column on the air separation device is correspondingly increased according to a calculation result; by further rectifying and purifying the waste nitrogen of the upper column, the waste nitrogen is purified into pure nitrogen, and the product volume of the increased pure nitrogen is obtained. The method further includes the steps that mediums in a pure nitrogen channel and mediums in a waste nitrogen channel of the air separation device are exchanged, the lost cooling capacity, caused by reduction of the amount of the waste nitrogen, of a water cooling tower and a molecular sieve purifier is calculated, and cold loss is compensated for by additionally arranging a freezing machine and a liquid nitrogen evaporator. Besides, the yield of product nitrogen can change according to requirements in the range that the ratio of product oxygen to the nitrogen is 1:1 to 1:3. According to the method, the oxygen and nitrogen design proportion of an original air separation device is changed at low improvement cost, and the yield of pure nitrogen products is obtained to the largest extent.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

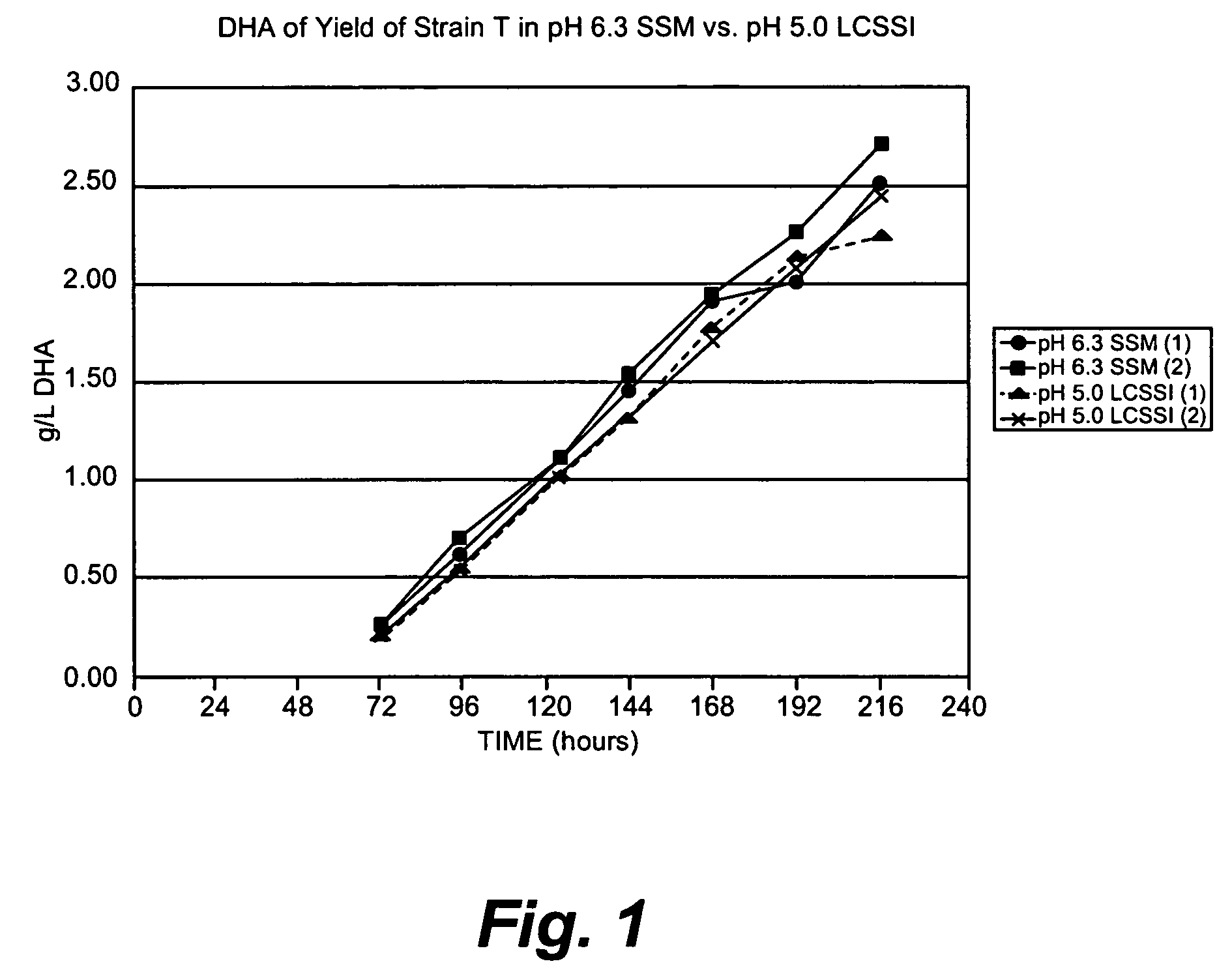

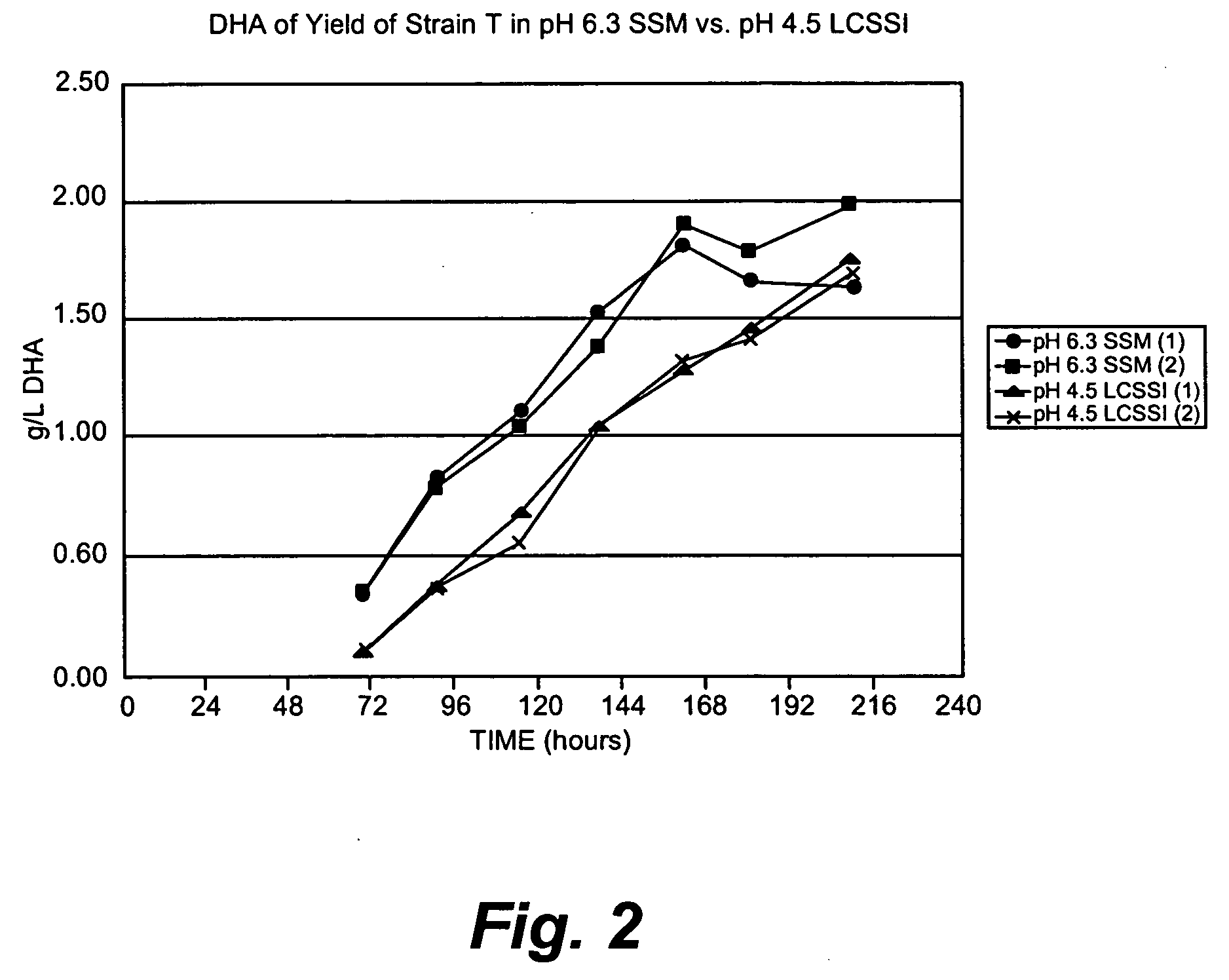

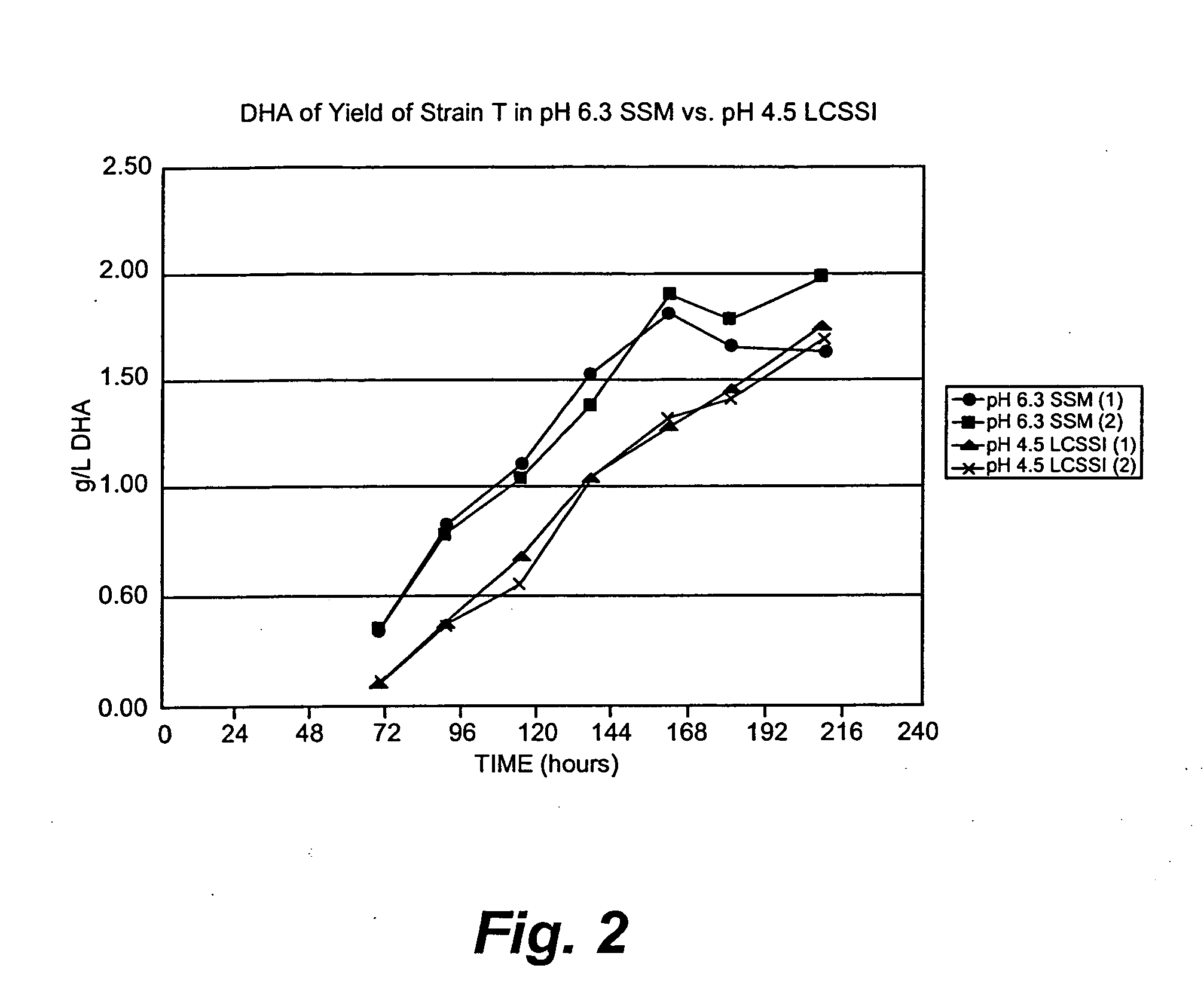

Production of high levels of DHA in microalgae using modified amounts of chloride and potassium

ActiveUS20050112736A1Minimize chloride levelLower Level RequirementsUnicellular algaeCulture processMicroorganismPotassium Ion Level

Methods for production of highly unsaturated fatty acids by marine microorganisms, including the heterotrophic marine dinoflagellate Crypthecodinium, using low levels of chloride ion are disclosed. Specifically, methods of increasing production of highly unsaturated fatty acids by marine microorganisms while growing in low chloride media by manipulating sodium ion and potassium ion levels. The invention also relates to methods of production of highly unsaturated fatty acids by marine organisms at low pH levels, and includes methods for generation of low pH tolerant strains.

Owner:DSM IP ASSETS BV

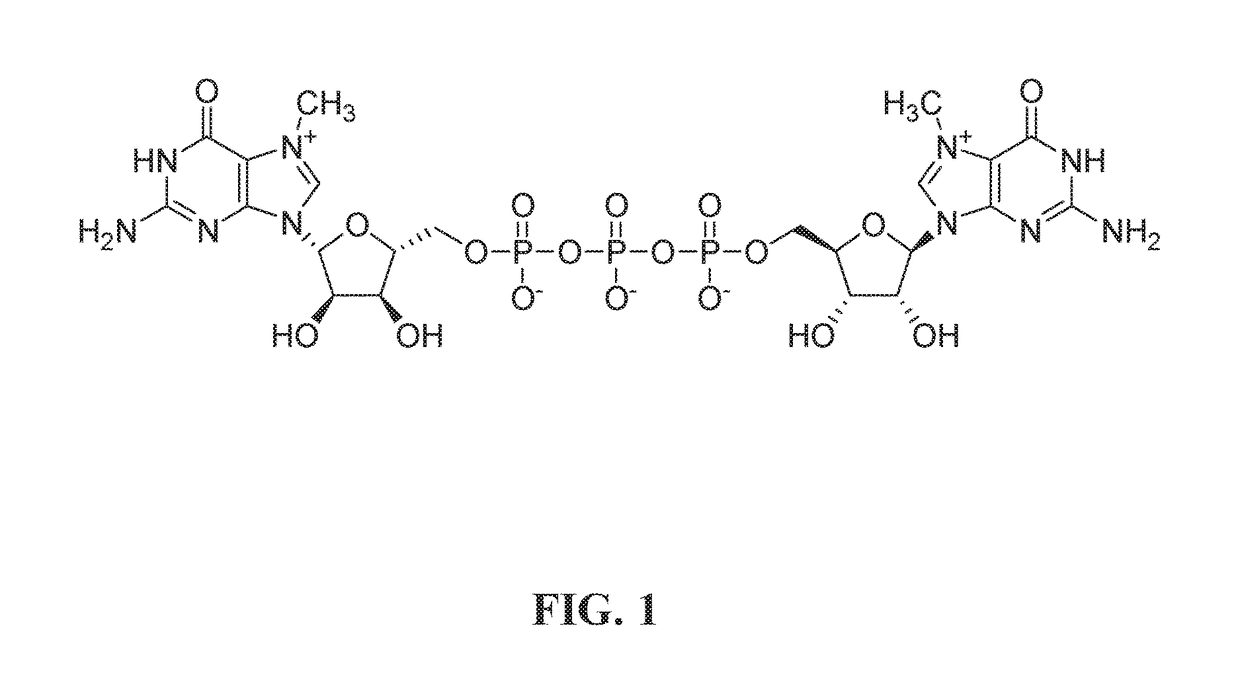

T7 RNA polymerase variants

ActiveUS20190002850A1High expressionImprove stabilityTransferasesGenetic engineeringT7 RNA polymeraseMedicine

The present invention provides engineered RNA polymerase variants and compositions comprising these variants. The present invention further provides engineered T7 RNA polymerase variants and compositions comprising these variants. These variants have been evolved for selective incorporation of the m7G(5′)ppp(5′)m7G cap analog over GTP at the initiation of in vitro transcription. The present invention also provides methods for selective capping of RNA transcripts.

Owner:CODEXIS INC

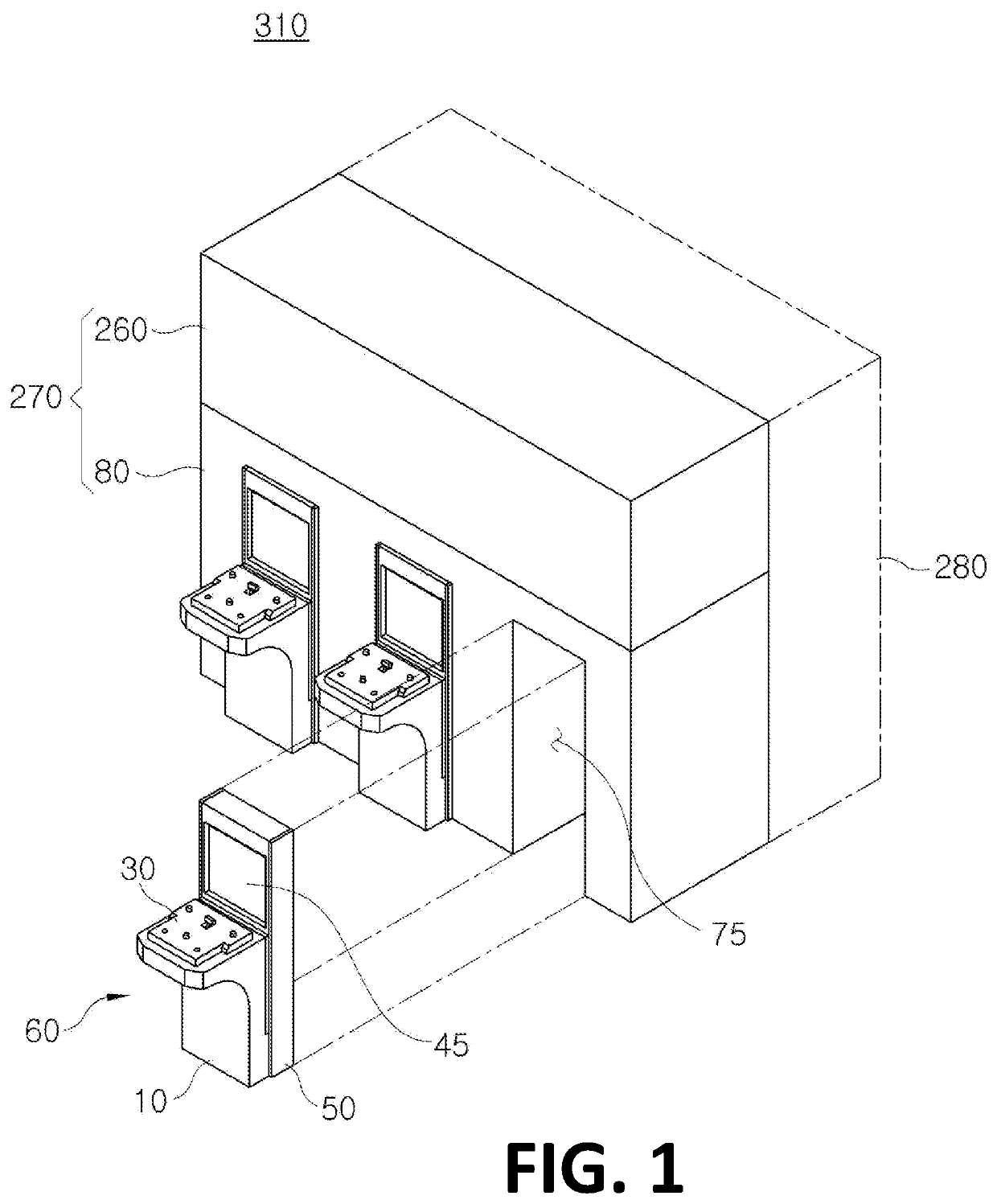

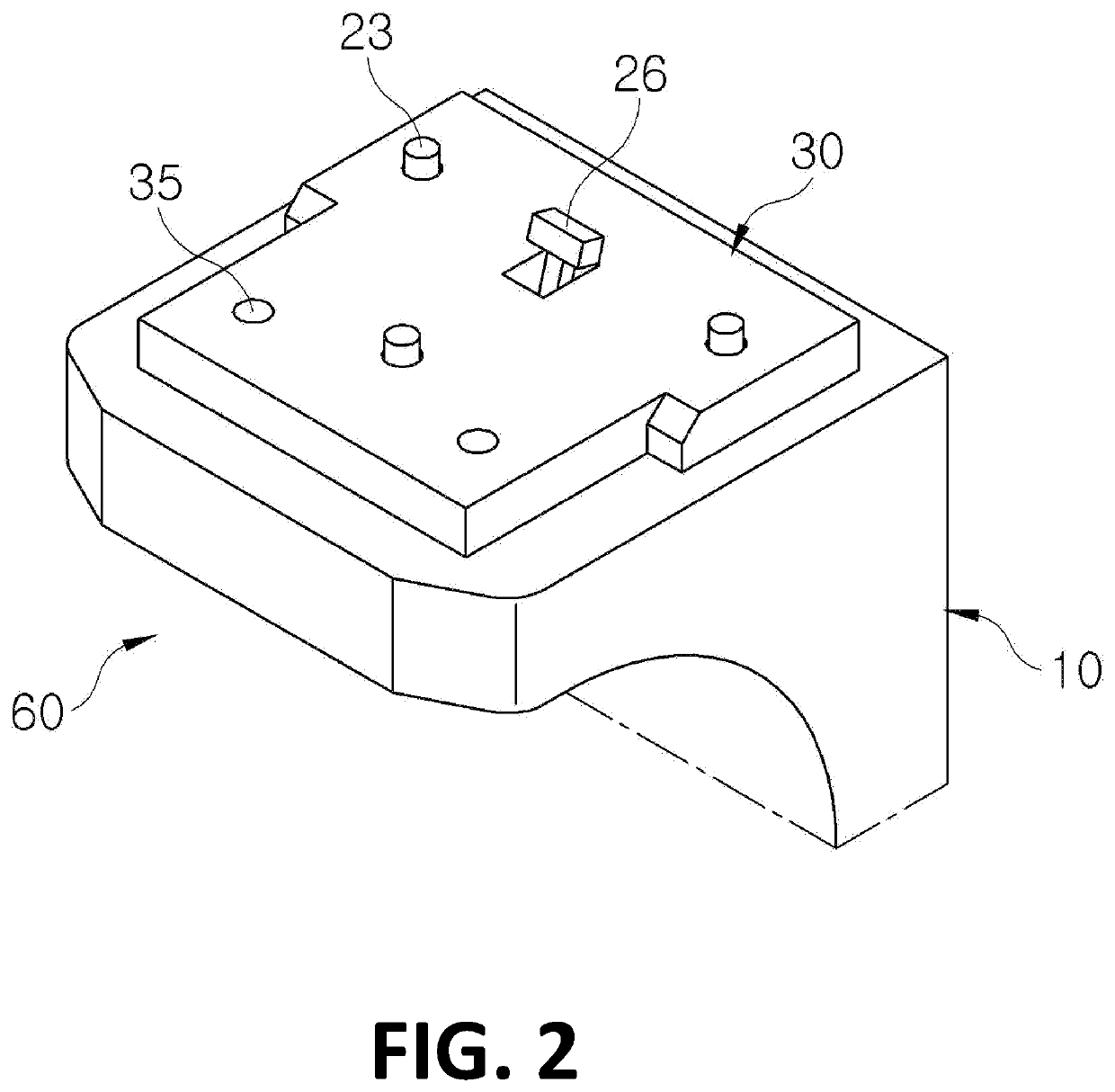

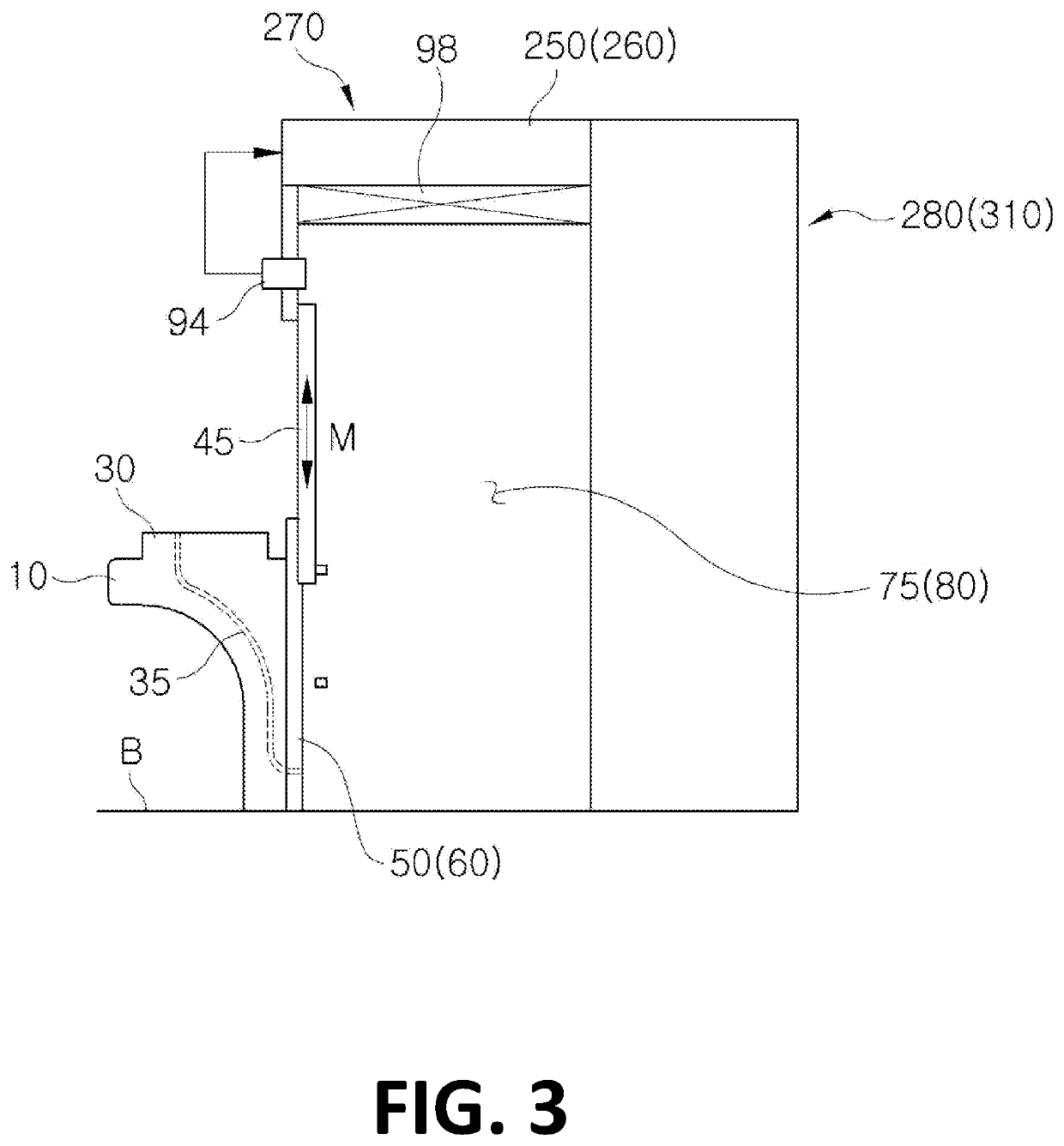

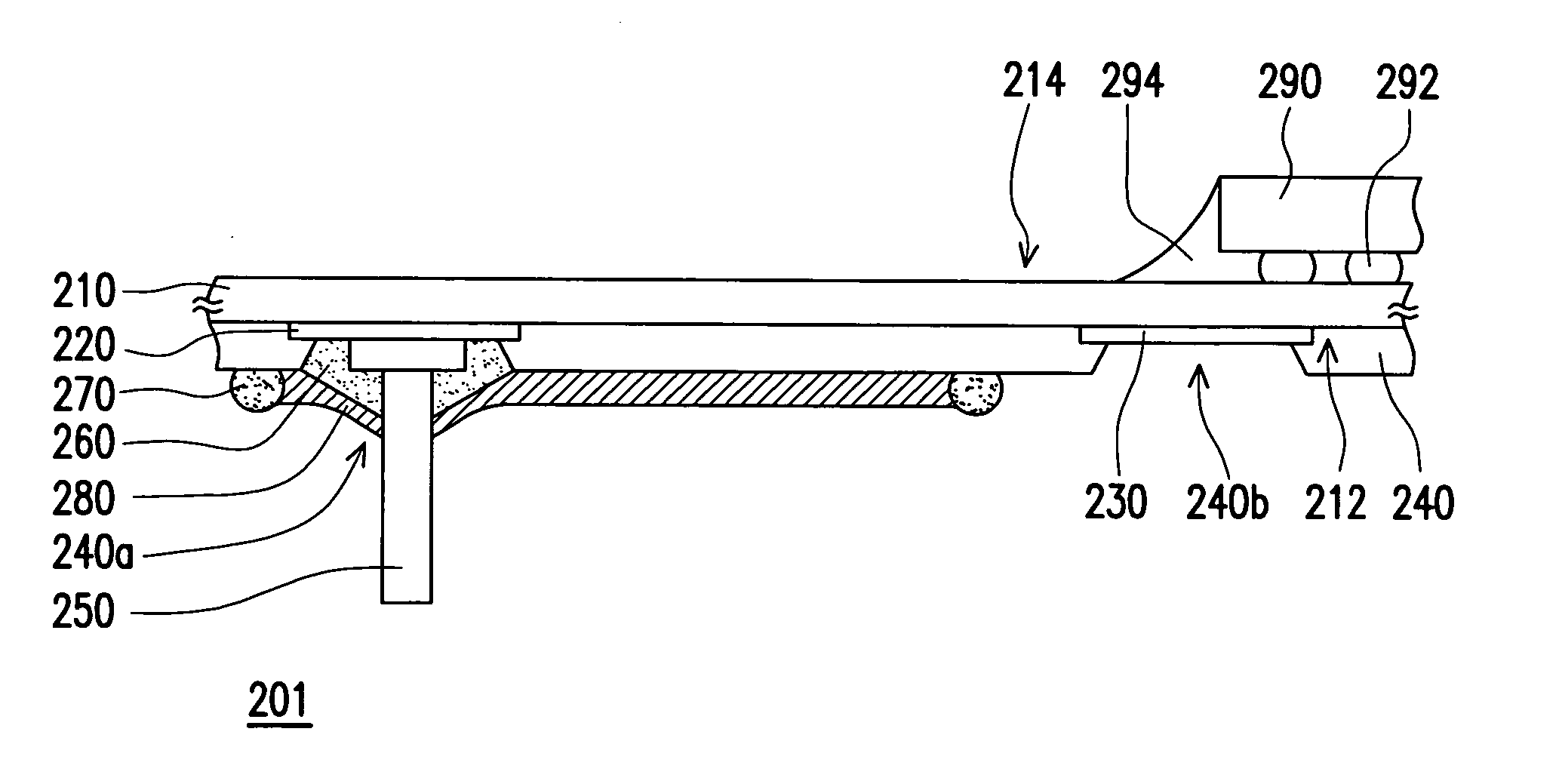

Semiconductor manufacturing device

InactiveUS20200219744A1Low costImprove the environmentSemiconductor/solid-state device manufacturingConveyor partsEngineeringMechanical engineering

A semiconductor manufacturing device, according to the present invention, comprises a load port unit, a substrate transfer unit, and a processing unit sequentially arranged along a transfer path of a semiconductor substrate, wherein the load port unit has a load door relatively movable with respect to the substrate transfer unit while being accommodated in the substrate transfer unit, and an air introduction path for connecting the inside and the outside of the substrate transfer unit under the load door; and the substrate transfer unit has a substrate processing module for communicating with the load port unit and the processing unit while limiting a processing space of the semiconductor substrate, and an air supply module positioned on the substrate processing module so as to supply dry, purified air to the substrate processing module.

Owner:KIM SEONG LAE +2

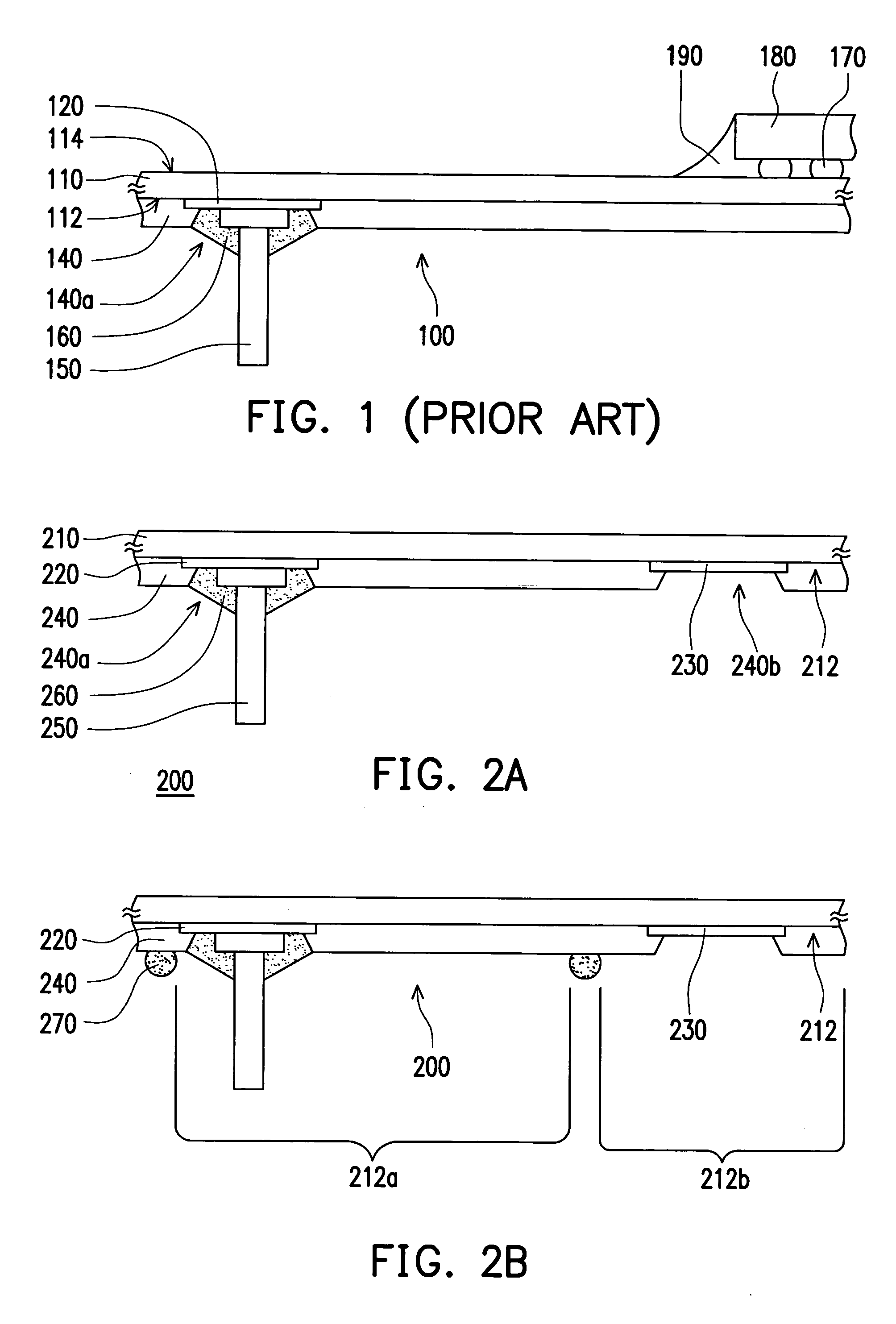

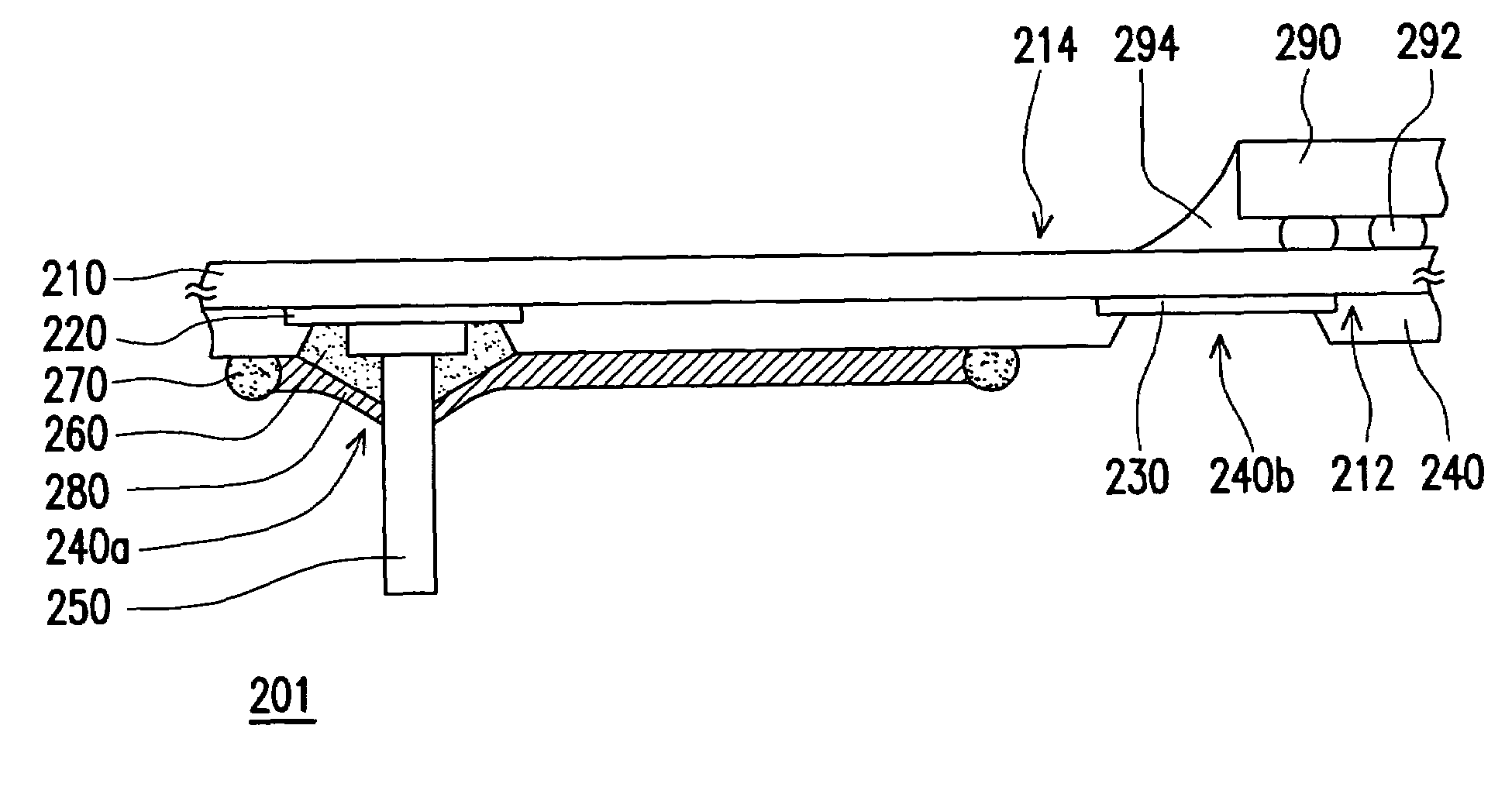

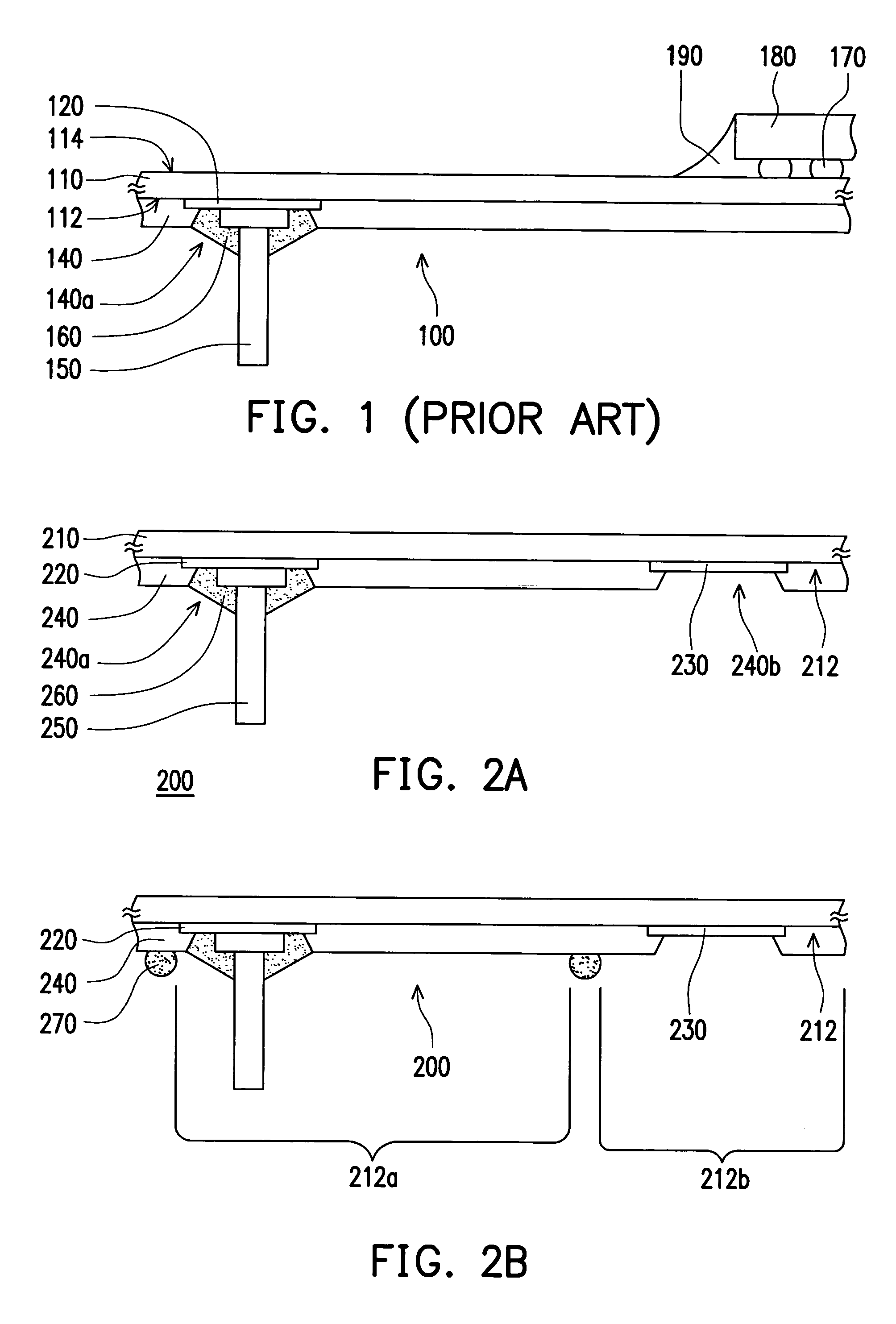

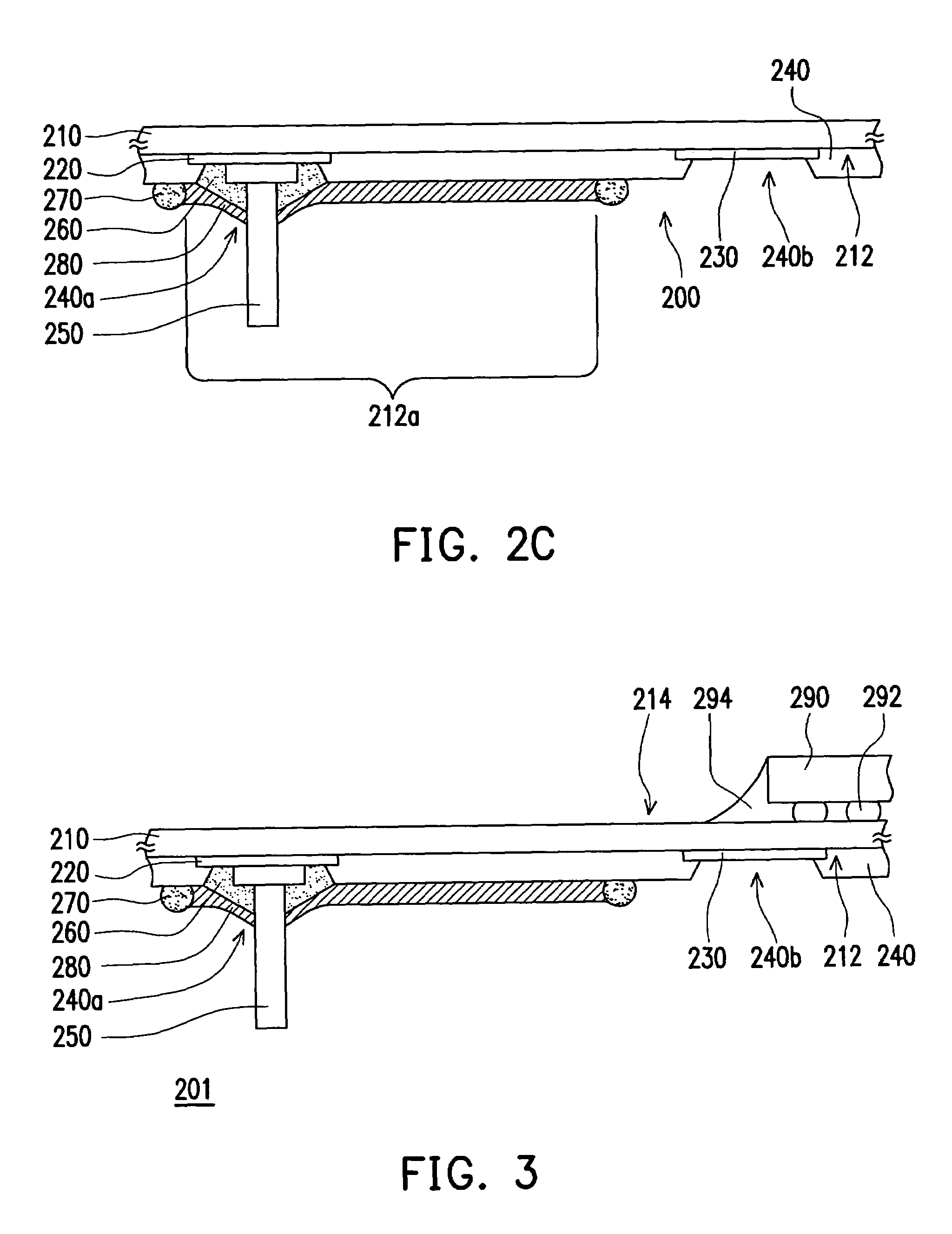

Circuit carrier and fabrication method thereof

ActiveUS20050263887A1Improve manufacturing yieldIncrease productionPrinted circuit assemblingFinal product manufactureSolder maskPin grid array

A circuit carrier adapted for a pin grid array (PGA) package is disclosed. The circuit carrier comprises a substrate, at least one pin pad, at least one solder mask layer, at least one solder layer, at least one pin and a fixing layer. The pin pad is disposed over the surface of the substrate. The solder mask layer is disposed over the surface of the substrate, and exposing at least a portion of the pin pad. The solder layer is disposed over the pin pad. One end of the pin connects to the pin pad through the solder layer. The fixing layer is disposed over the solder mask layer, and covering the solder layer and a portion of a side surface of the pin. When the solder layer melts due to a high process temperature, the fixing layer helps to fix the pin to the pin pad.

Owner:VIA TECH INC

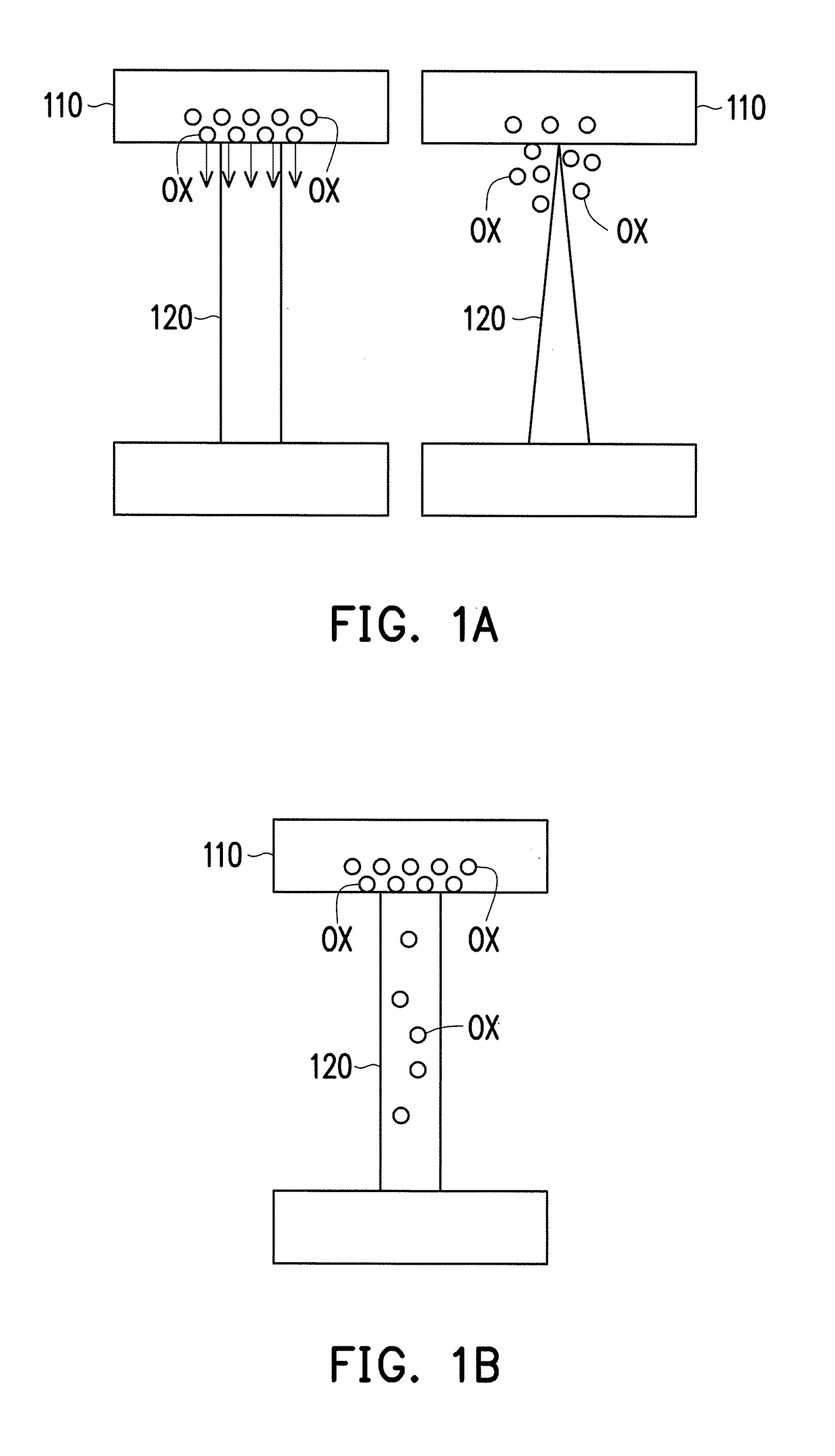

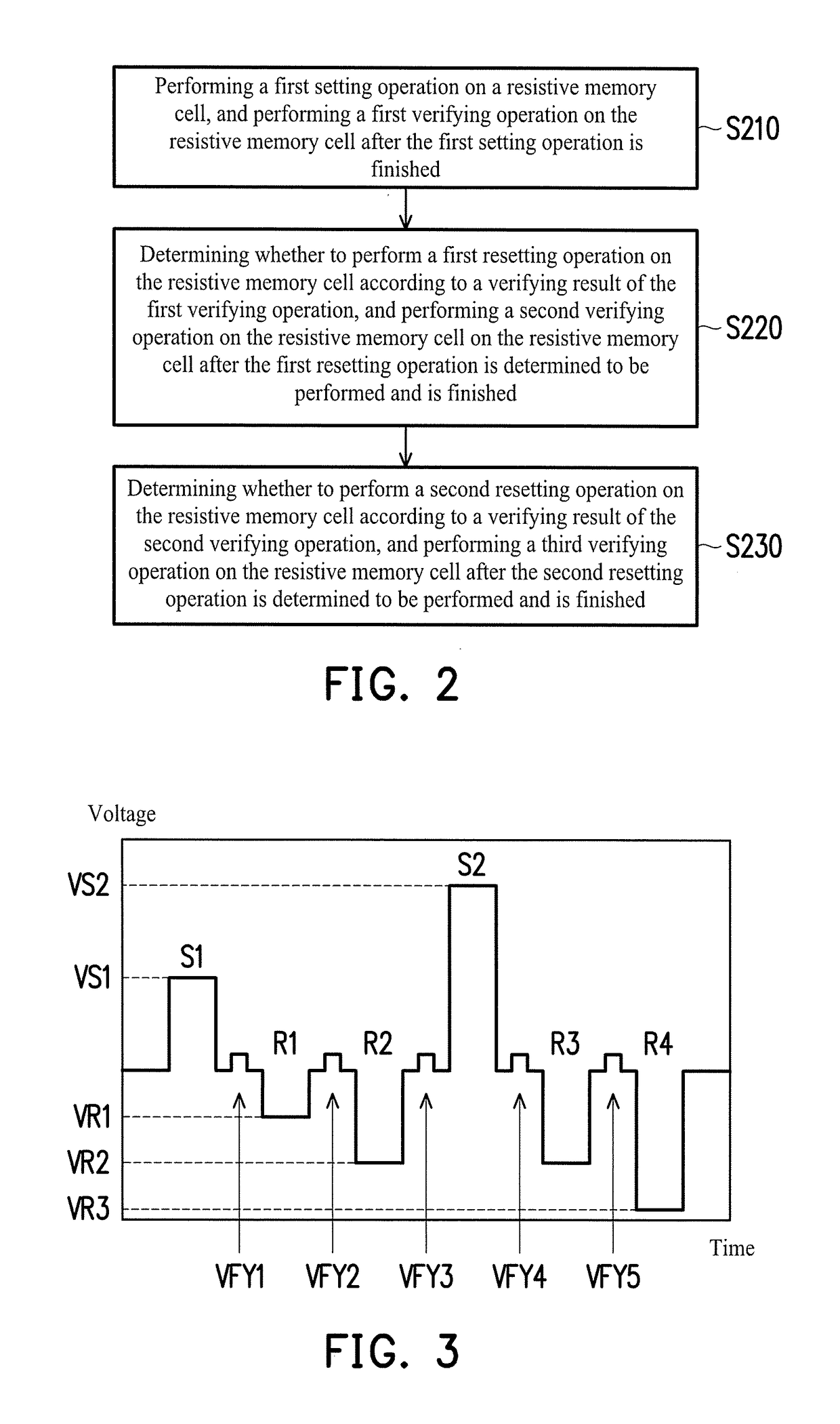

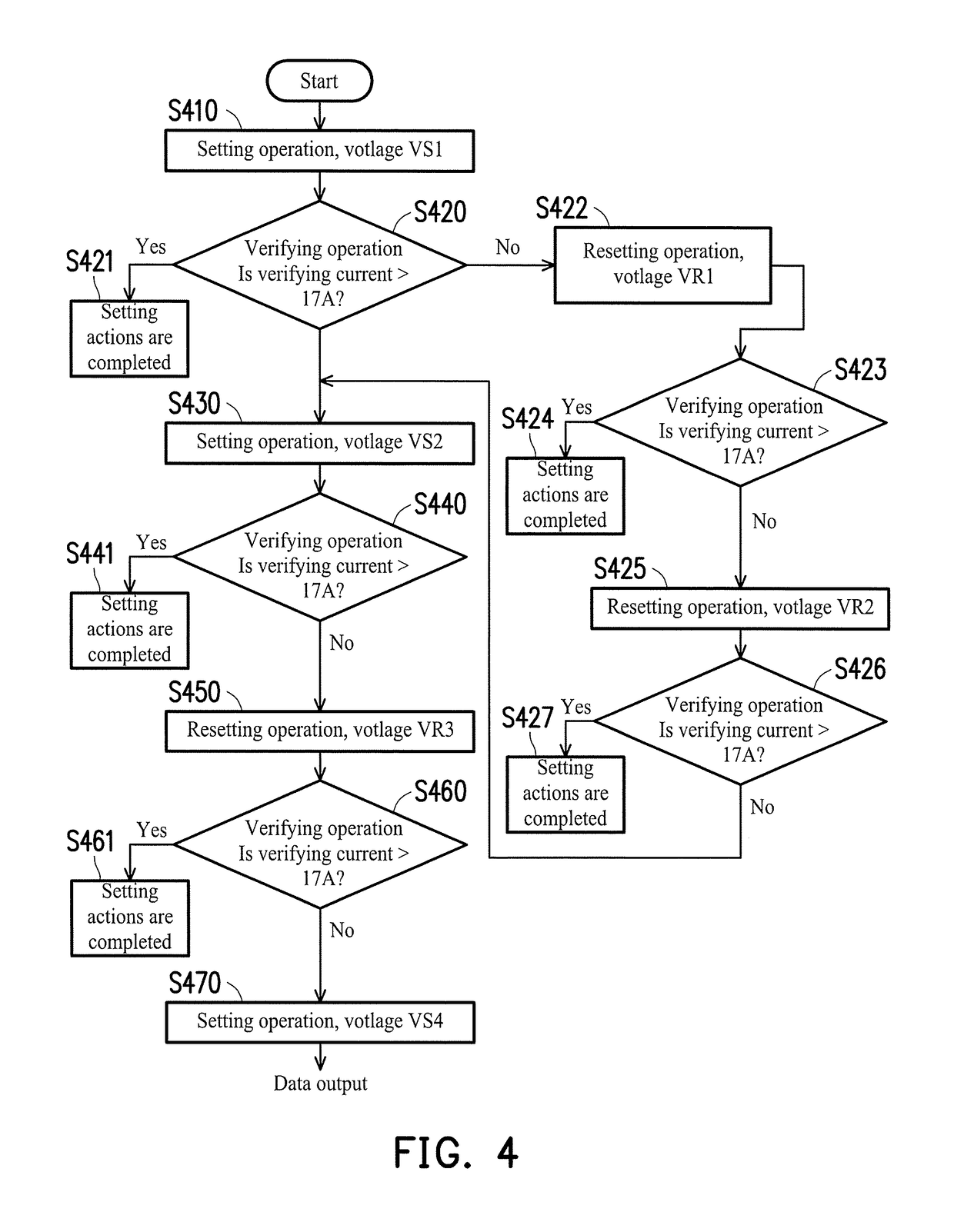

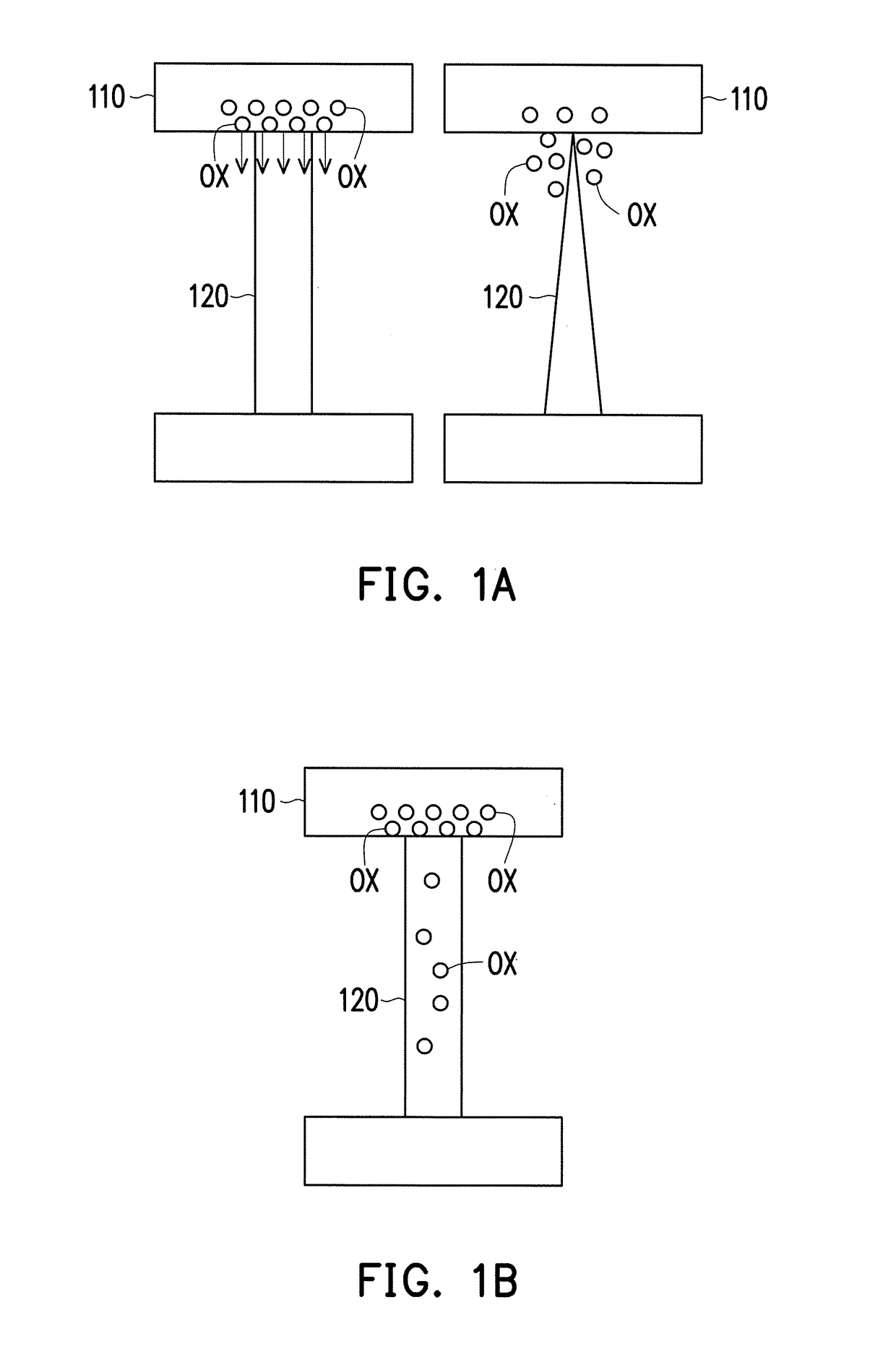

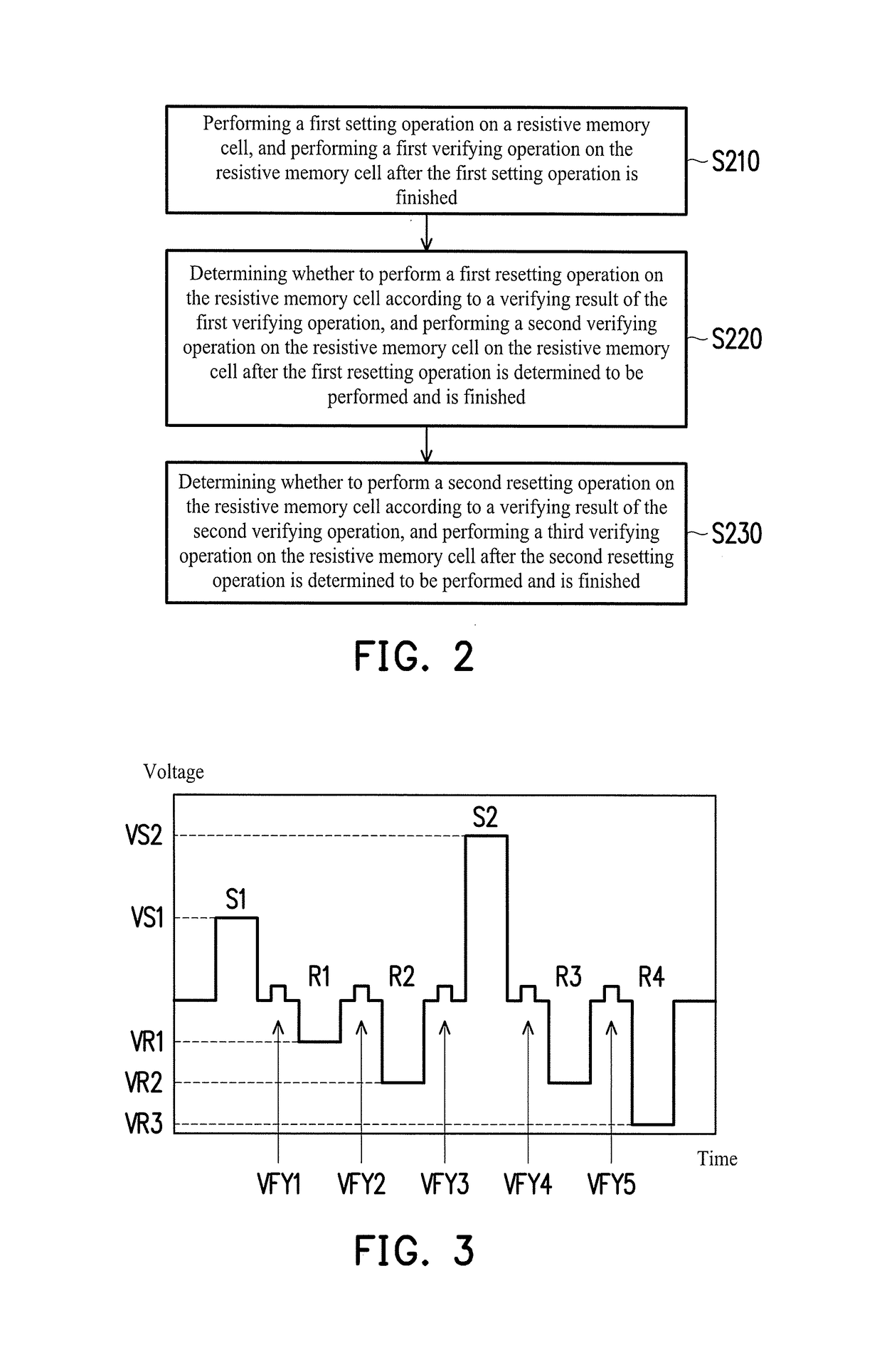

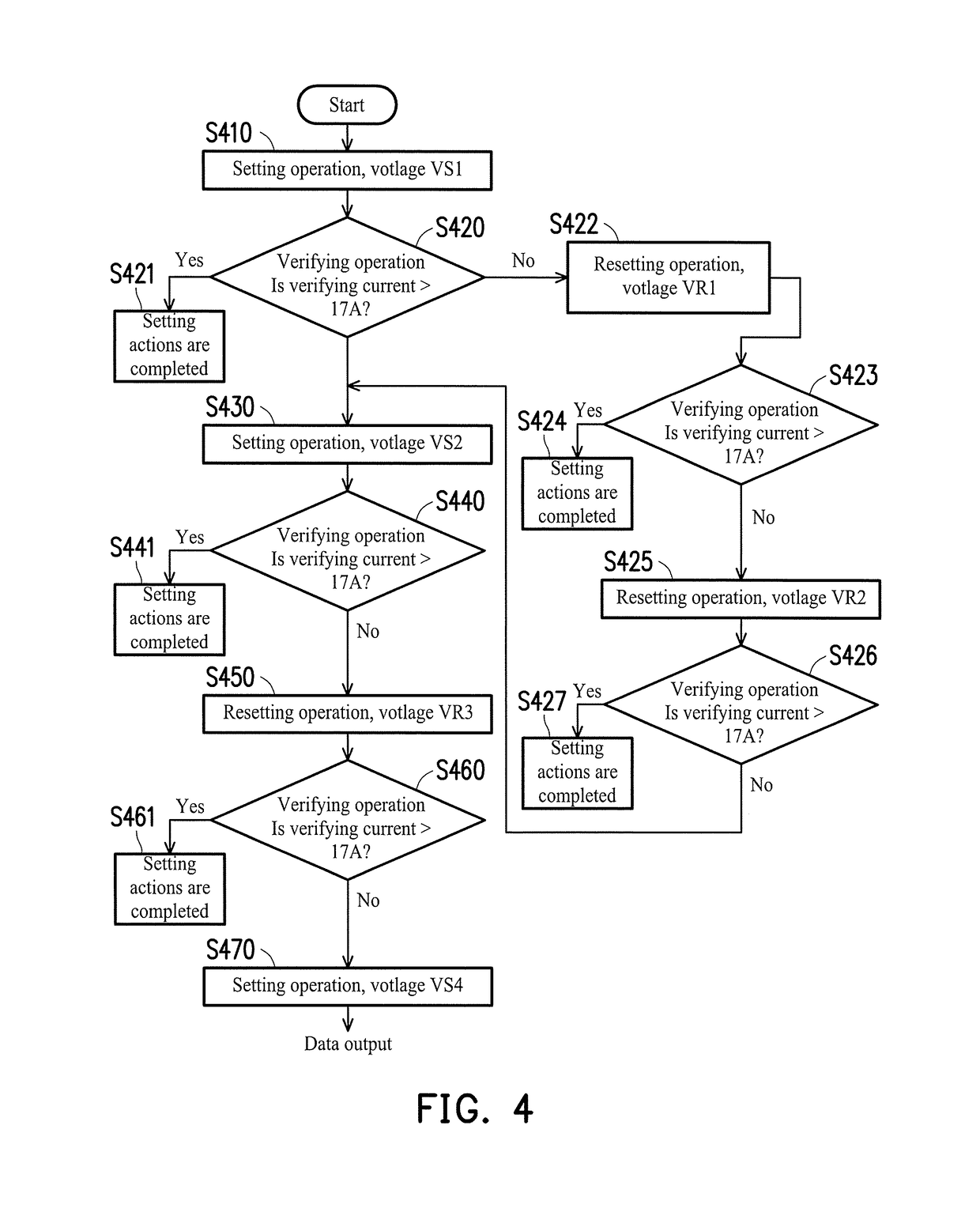

Resistive memory apparatus and setting method for resistive memory cell thereof

A resistive memory apparatus and a setting method for a resistive memory cell thereof are provided. The setting method includes: performing a first setting operation on the resistive memory cell, and performing a first verifying operation on the resistive memory cell after the first setting operation is finished; determining whether to perform a first resetting operation on the resistive memory cell according to a verifying result of the first verifying operation, and performing a second verifying operation on the resistive memory cell after the first resetting operation is determined to be performed and is finished; and determining whether to perform a second resetting operation on the resistive memory cell according to a verifying result of the second verifying operation, and performing a third verifying operation on the resistive memory cell after the second resetting operation is determined to be performed and is finished.

Owner:WINBOND ELECTRONICS CORP

Circuit carrier and fabrication method thereof

ActiveUS7102230B2Improve manufacturing yieldIncrease productionPrinted circuit assemblingFinal product manufactureSolder maskPin grid array

A circuit carrier adapted for a pin grid array (PGA) package is disclosed. The circuit carrier comprises a substrate, at least one pin pad, at least one solder mask layer, at least one solder layer, at least one pin and a fixing layer. The pin pad is disposed over the surface of the substrate. The solder mask layer is disposed over the surface of the substrate, and exposing at least a portion of the pin pad. The solder layer is disposed over the pin pad. One end of the pin connects to the pin pad through the solder layer. The fixing layer is disposed over the solder mask layer, and covering the solder layer and a portion of a side surface of the pin. When the solder layer melts due to a high process temperature, the fixing layer helps to fix the pin to the pin pad.

Owner:VIA TECH INC

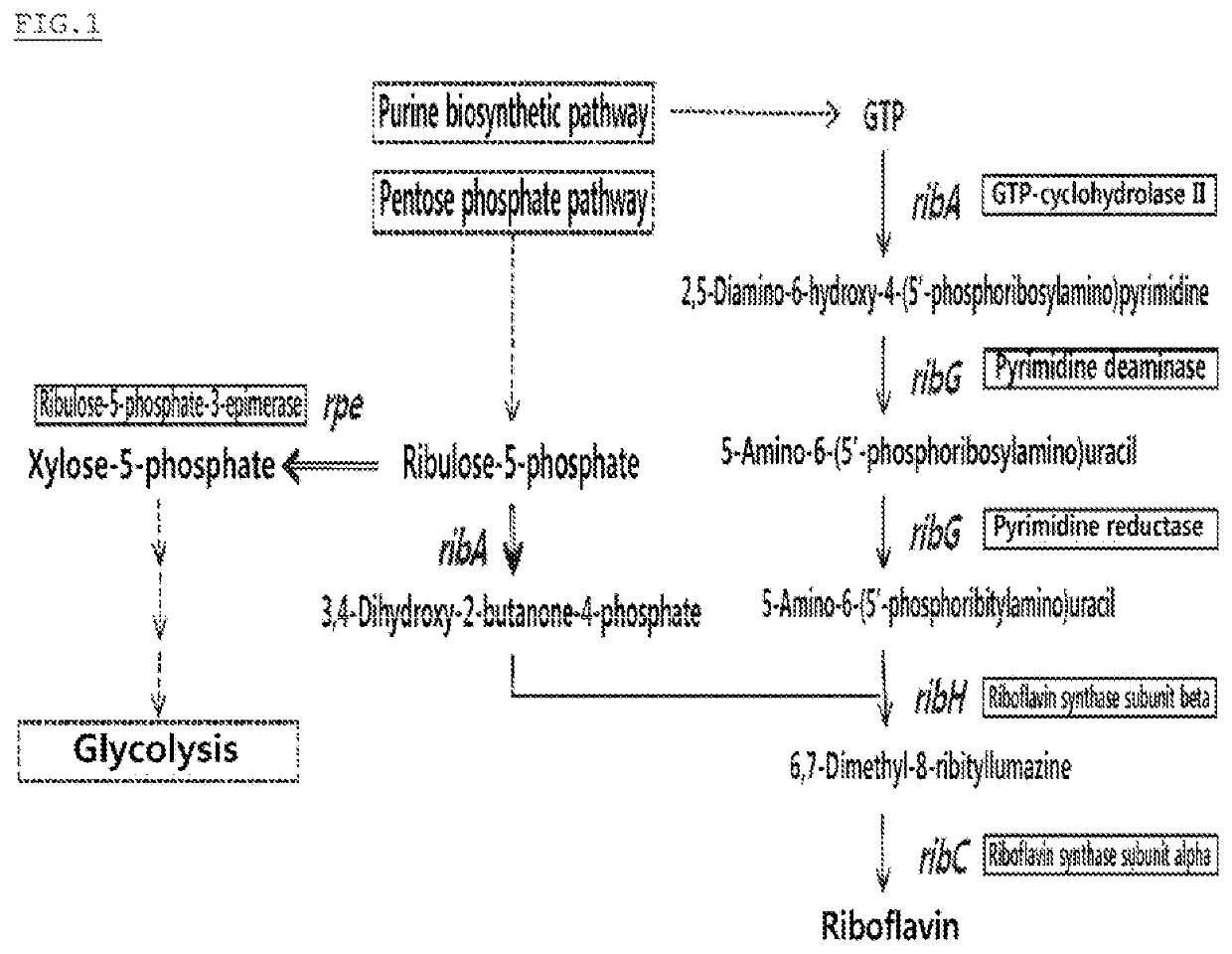

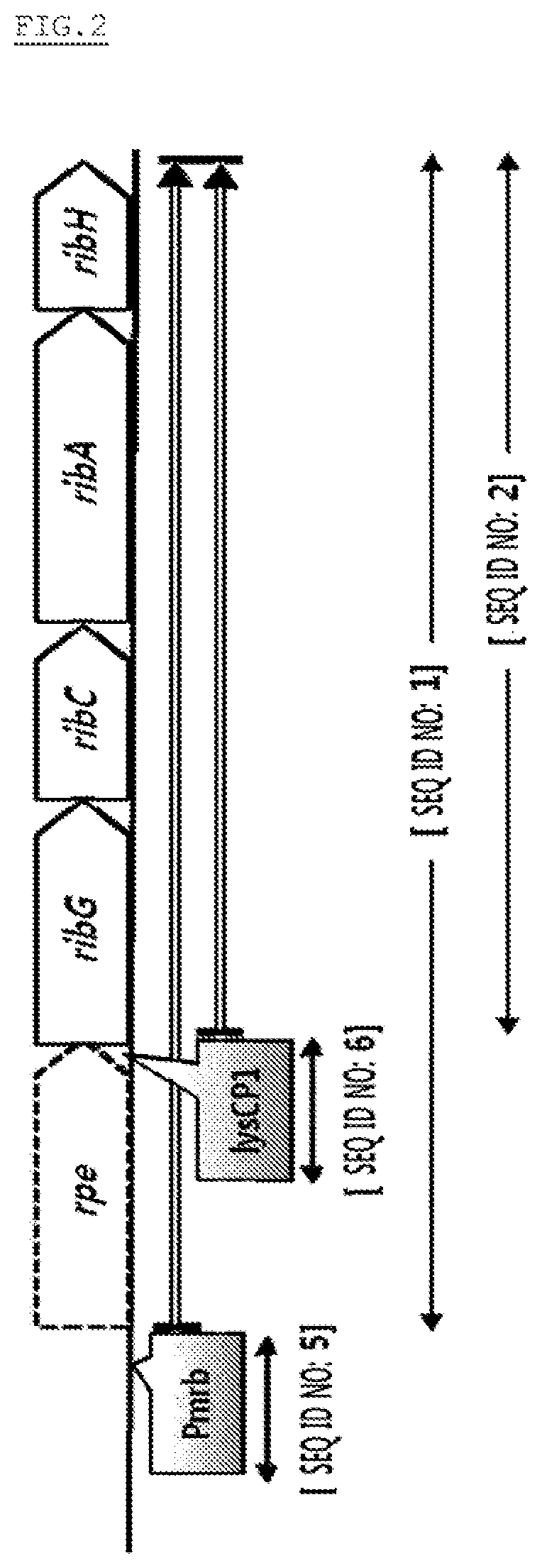

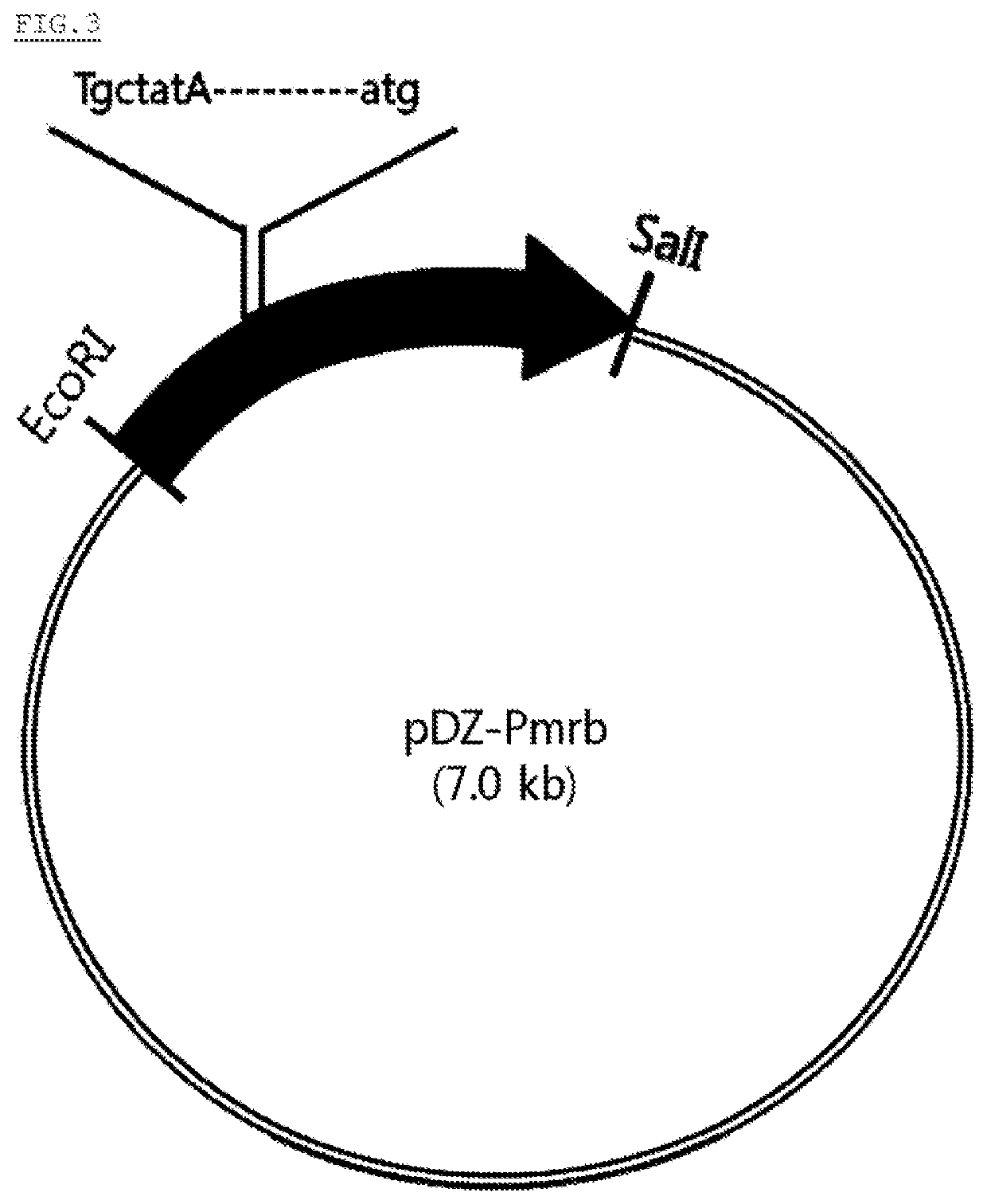

Microorganism for simultaneously producing L-amino acid and riboflavin, and method for producing L-amino acid and riboflavin using same

ActiveUS10590446B2Low production costGood effectBacteriaAccessory food factorsRiboflavin biosynthesisThreonine

The present invention relates to a method for producing highly-concentrated L-amino acid and riboflavin simultaneously, and a microorganism for simultaneously producing L-amino acid and riboflavin. Specifically, the present invention relates to a modified microorganism for producing L-lysine or L-threonine, and riboflavin simultaneously, wherein the microorganism belonging to Corynebacterium sp. capable of producing L-lysine or L-threonine is modified by enhancing the activity of an enzyme family expressed by a rib operon which contains riboflavin biosynthesis gene family. Also, the present invention relates to a method for the simultaneous production of L-lysine or L-threonine, and riboflavin using the modified microorganism, and relates to a formulation or granular formulation, feed, and feed additive, containing L-lysine or L-threonine, and riboflavin produced from a culture medium of the modified microorganism.

Owner:CJ CHEILJEDANG CORP

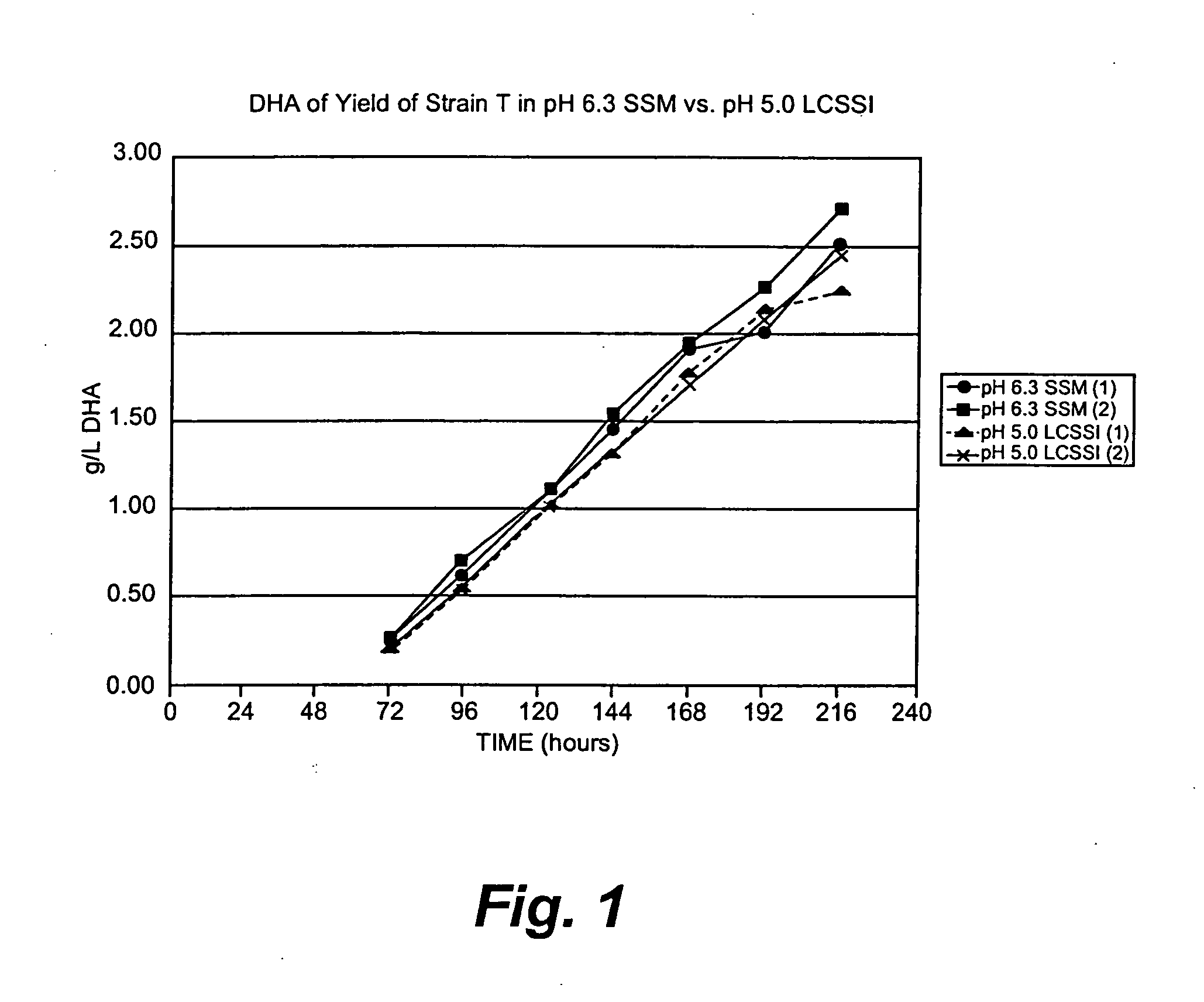

Production of DHA in microalgae in low pH medium

ActiveUS20060100279A1Minimize chloride levelLower Level RequirementsBiocideUnicellular algaeMicroorganismPotassium Ion Level

Methods for production of highly unsaturated fatty acids by marine microorganisms, including the heterotrophic marine dinoflagellate Crypthecodinium, using low levels of chloride ion are disclosed. Specifically, methods of increasing production of highly unsaturated fatty acids by marine microorganisms while growing in low chloride media by manipulating sodium ion and potassium ion levels. The invention also relates to methods of production of highly unsaturated fatty acids by marine organisms at low pH levels, and includes methods for generation of low pH tolerant strains.

Owner:DSM IP ASSETS BV

Technical method for rapid asexual propagation and anti-enhancement of hybrid bollgard F1

The invention relates to a technical method for rapid asexual propagation and anti-enhancement of hybrid bollgard F1, which comprises the main steps of: firstly, identifying perennial cotton germplasm resources capable of naturally overwintering, and resisting fusarium wilt resistance and greensickness; adopting the perennial cotton germplasm resources as rootstock, scioning and grafting with the hybrid bollgard F1, and cultivating perennial root to obtain grafted plants; and secondly, carrying out large-scale propagation of hybrid bollgard F1 seedlings by using the method, and directly using the hybrid bollgard F1 seeldings for agricultural production. According to the technical method for rapid asexual propagation and anti-enhancement of the hybrid bollgard F1, field cotton hybrid seed production is free, the seed production process of the hybrid bollgard F1 is simplified, the seed purity of the hybrid bollgard F1 is improved, and the disease resistance of the hybrid bollgard F1 is enhanced. The method can be used for large-scale propagation of hybrid bollgard F1 seedlings with obviously improved anti-enhancement property, and is applied to agricultural production.

Owner:HUBEI PROVINCIAL SEED GRP CO LTD

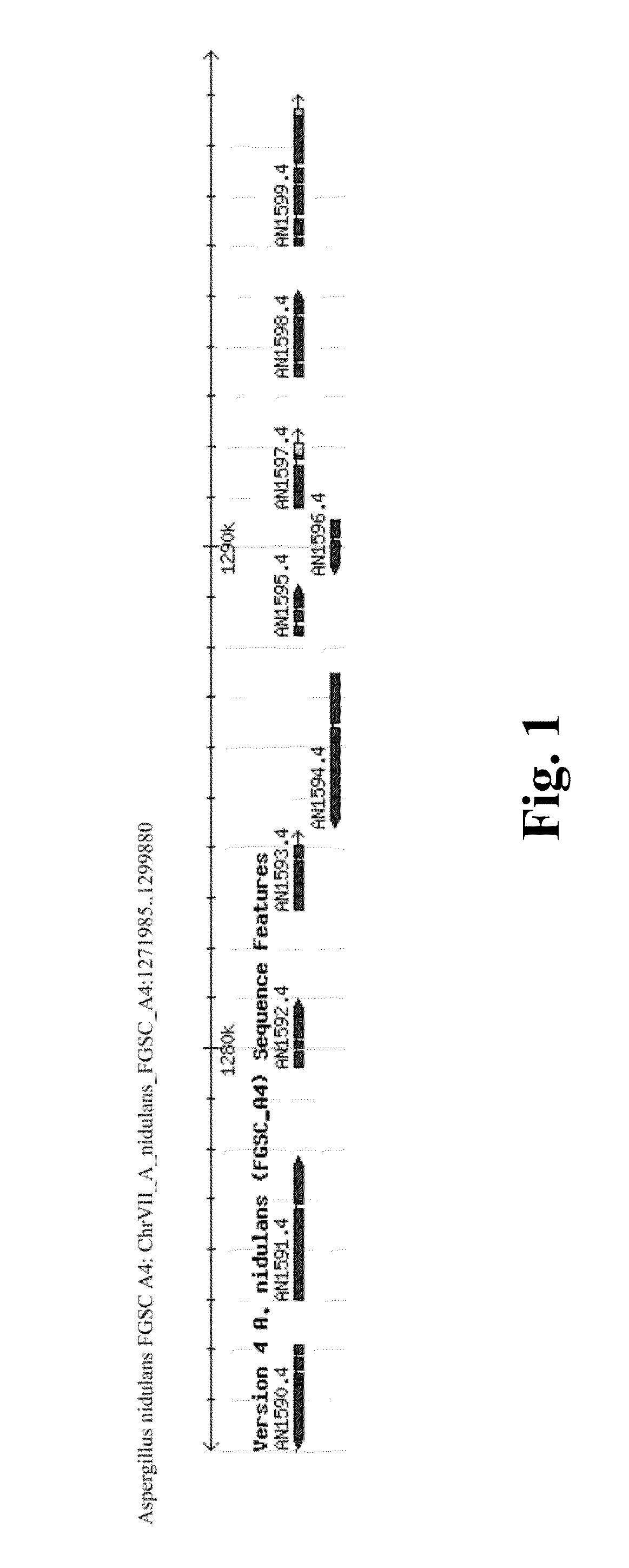

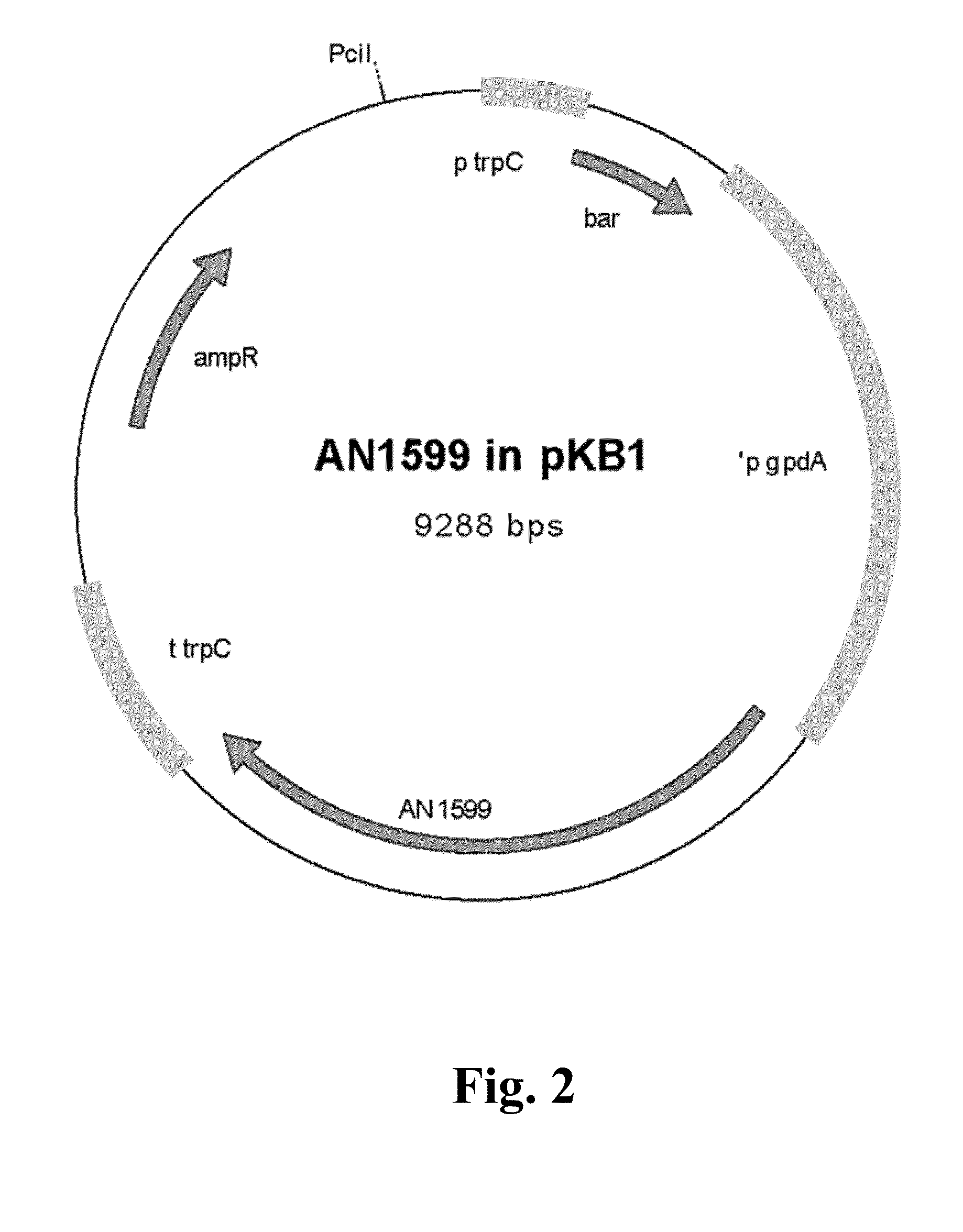

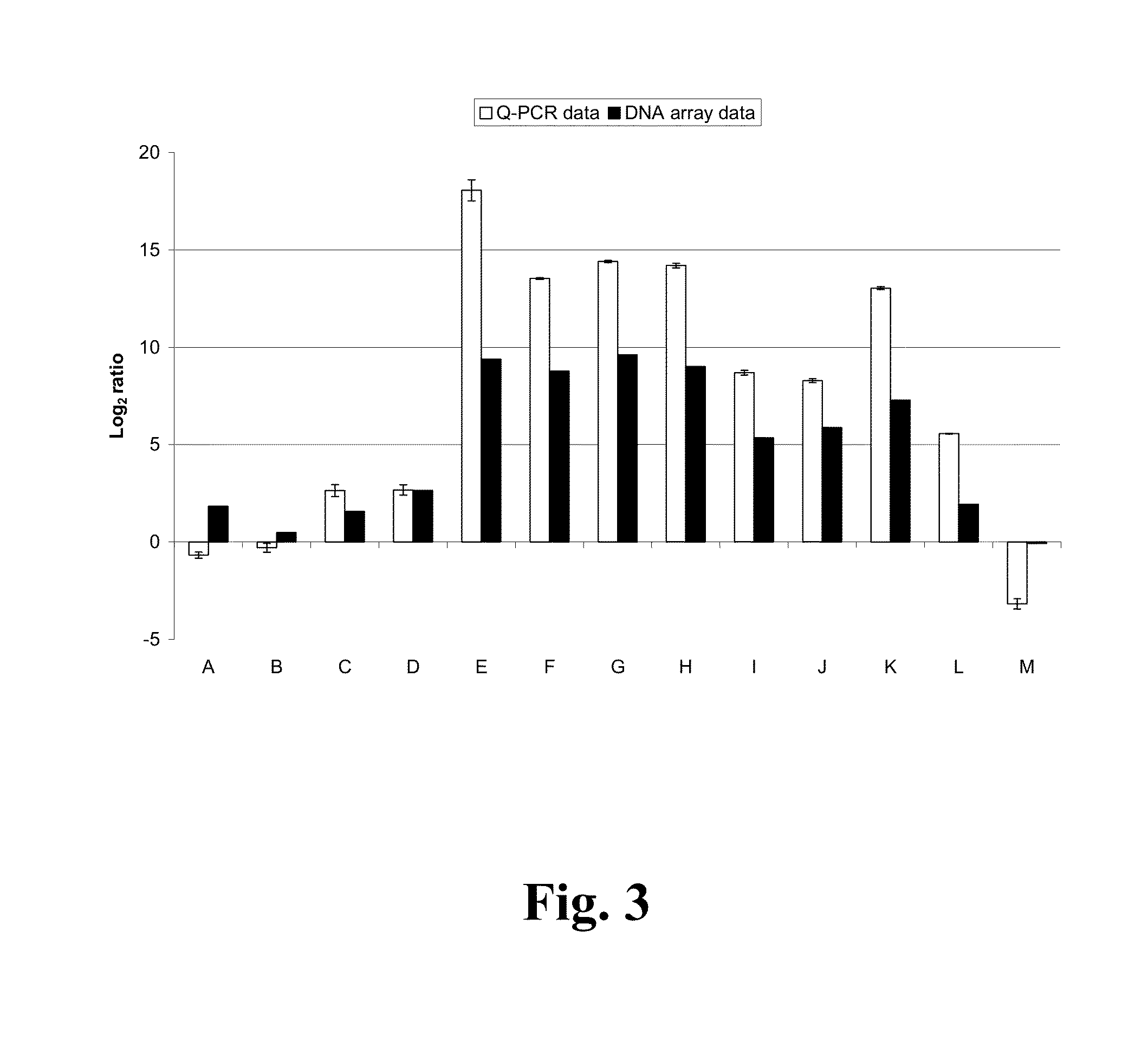

Method for producing terpenes

InactiveUS20160194674A1Yield of productImprove yieldMicroorganismsTransferasesTranscription factorBiotechnology

The present invention concerns a method for producing terpenes in fungi comprising the steps of (a) providing a modified terpene biosynthetic gene cluster inside a host cell, wherein one or more of the naturally occurring genes or promoters of the cluster have been replaced, truncated or removed, (b) providing a transcription factor inside the host cell, the transcription factor activating the terpene biosynthetic gene cluster; (c) cultivating said host in conditions allowing the expression of the transcription factor activating the cluster; and optionally (d) recovering the thus produced terpene product.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT OY

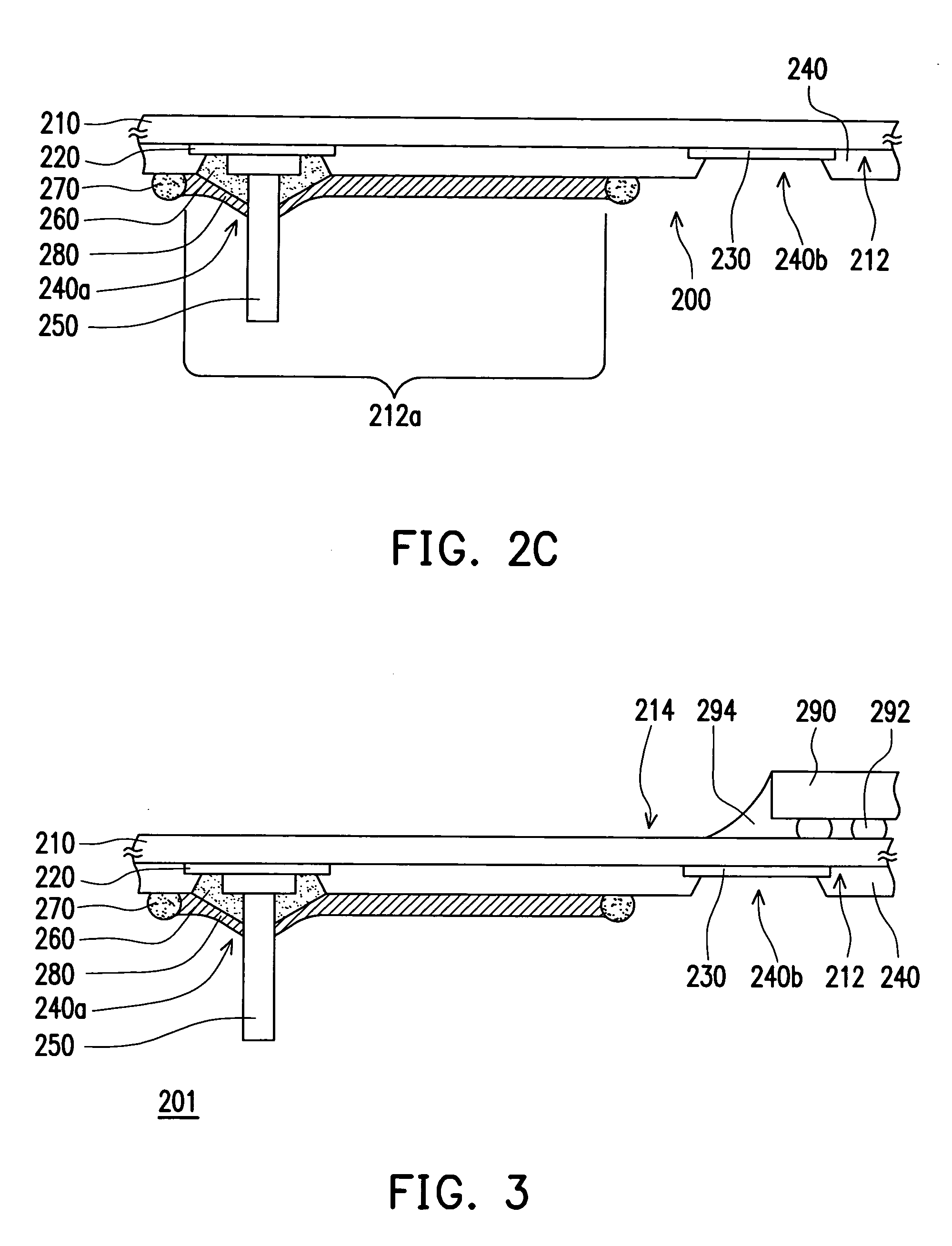

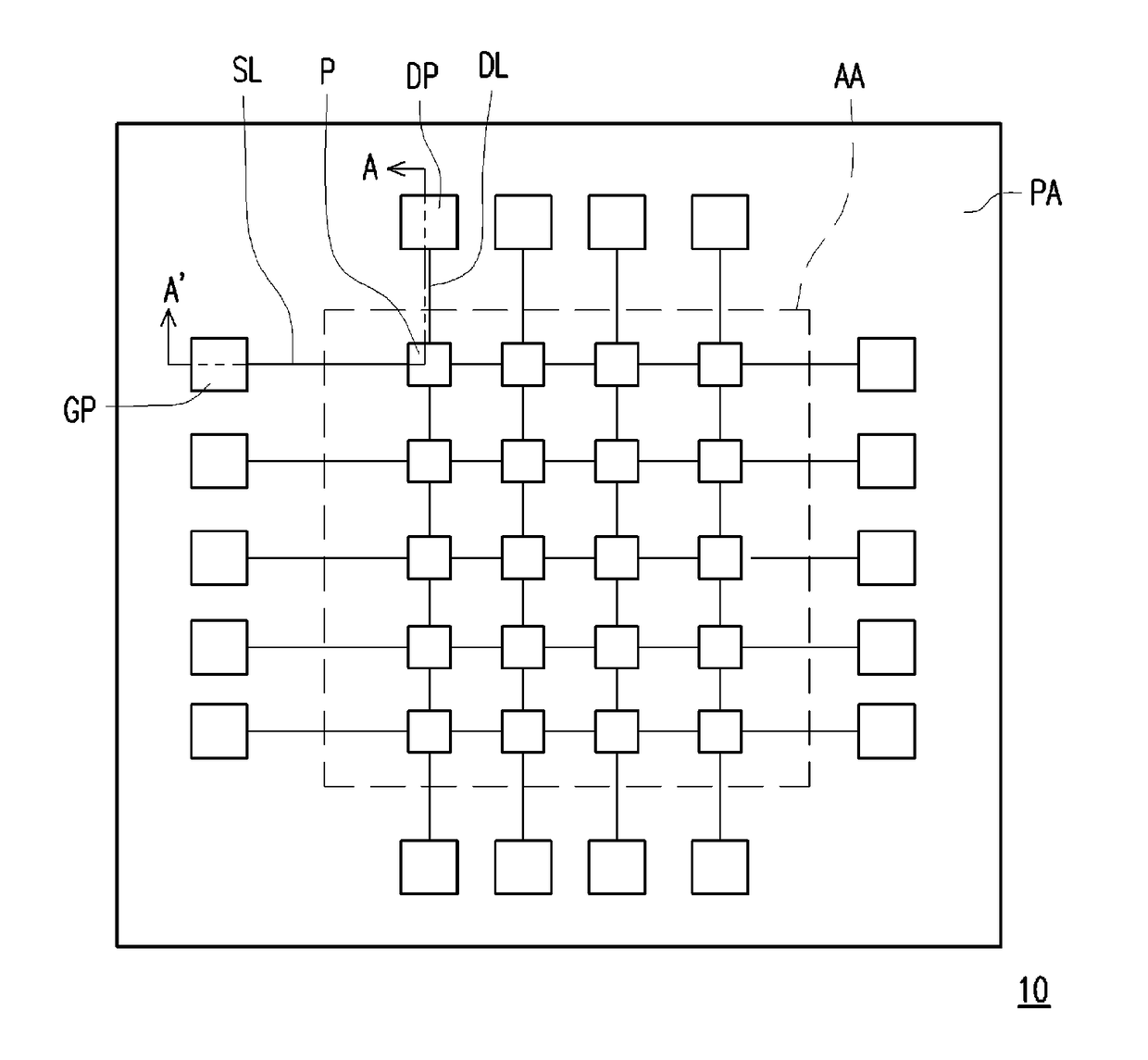

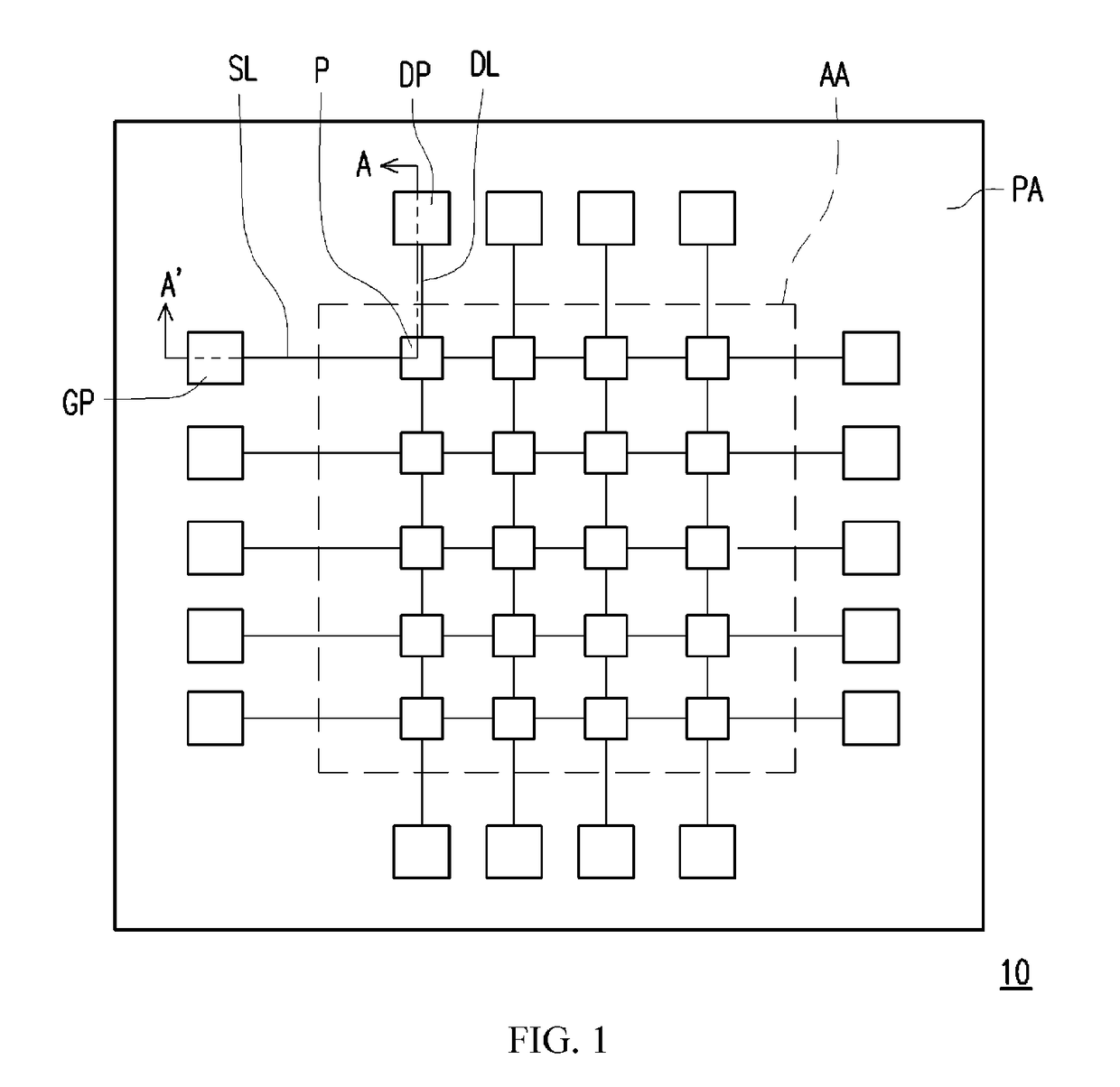

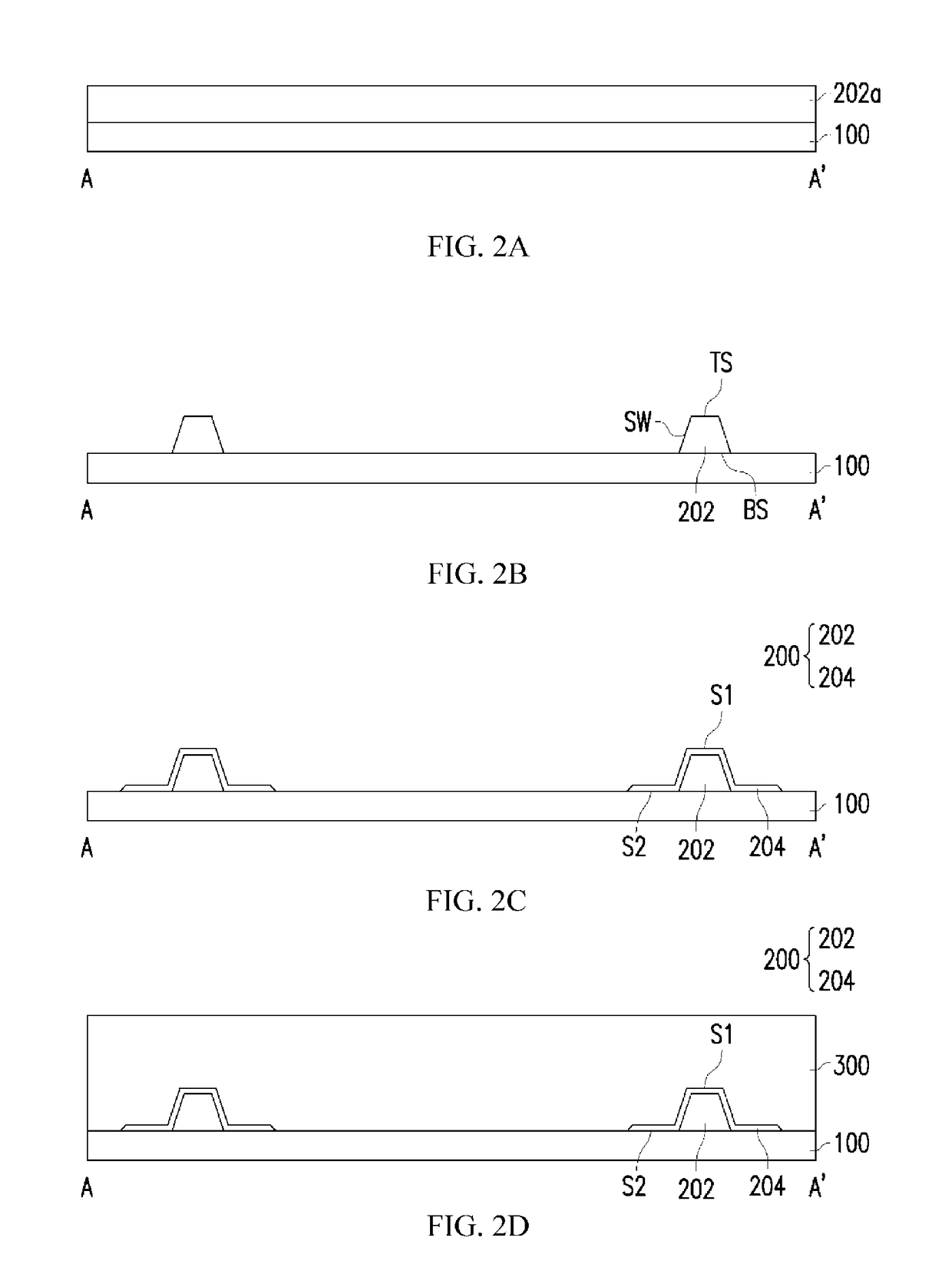

Conductive device substrate, method for manufacturing conductive device substrate, and display panel

InactiveUS20170256738A1Reduce spacingMaintain productionSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSurface plate

Owner:AU OPTRONICS CORP

Resistive memory apparatus and setting method for resistive memory cell thereof

A resistive memory apparatus and a setting method for a resistive memory cell thereof are provided. The setting method includes: performing a first setting operation on the resistive memory cell, and performing a first verifying operation on the resistive memory cell after the first setting operation is finished; determining whether to perform a first resetting operation on the resistive memory cell according to a verifying result of the first verifying operation, and performing a second verifying operation on the resistive memory cell after the first resetting operation is determined to be performed and is finished; and determining whether to perform a second resetting operation on the resistive memory cell according to a verifying result of the second verifying operation, and performing a third verifying operation on the resistive memory cell after the second resetting operation is determined to be performed and is finished.

Owner:WINBOND ELECTRONICS CORP

Efficient cultivation method of osmanthus fragrans

InactiveCN107253874AImprove survival rateUniform growthBiocideExcrement fertilisersDiseasePlant cultivation

The invention belongs to the technical field of plant cultivation and provides an efficient cultivation method of osmanthus fragrans. The efficient cultivation method includes the steps of 1), pretreatment of soil; 2), selection and treatment of cutting branches; 3), treatment of ends of the cutting branches; 4), cutting; 5), management after cutting. With the method, the survival rate in cultivation of the osmanthus fragrans is increased, disease resistance of the osmanthus fragrans is enhanced, and adaptability is improved.

Owner:和县赭洛山茶叶种植专业合作社

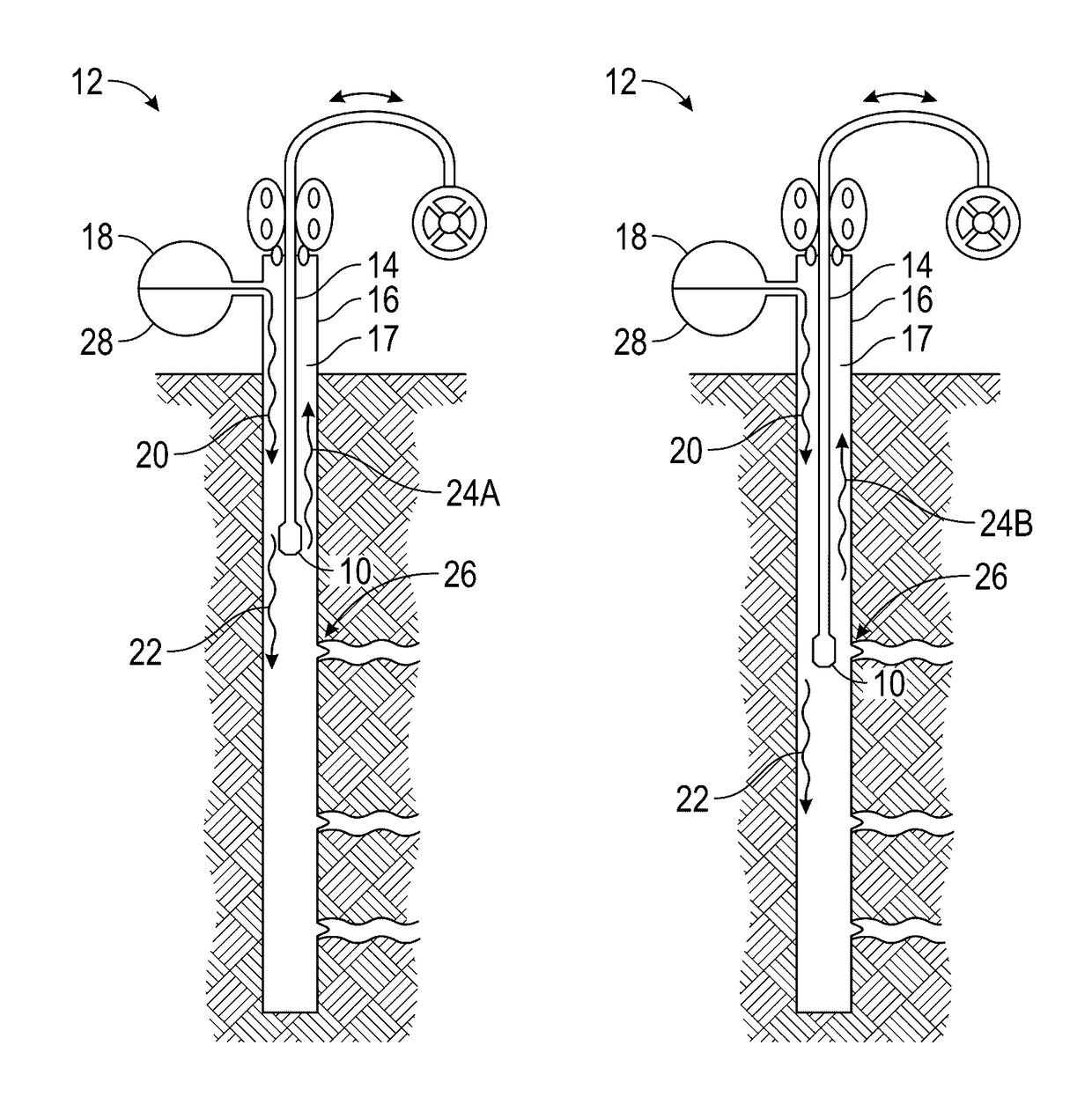

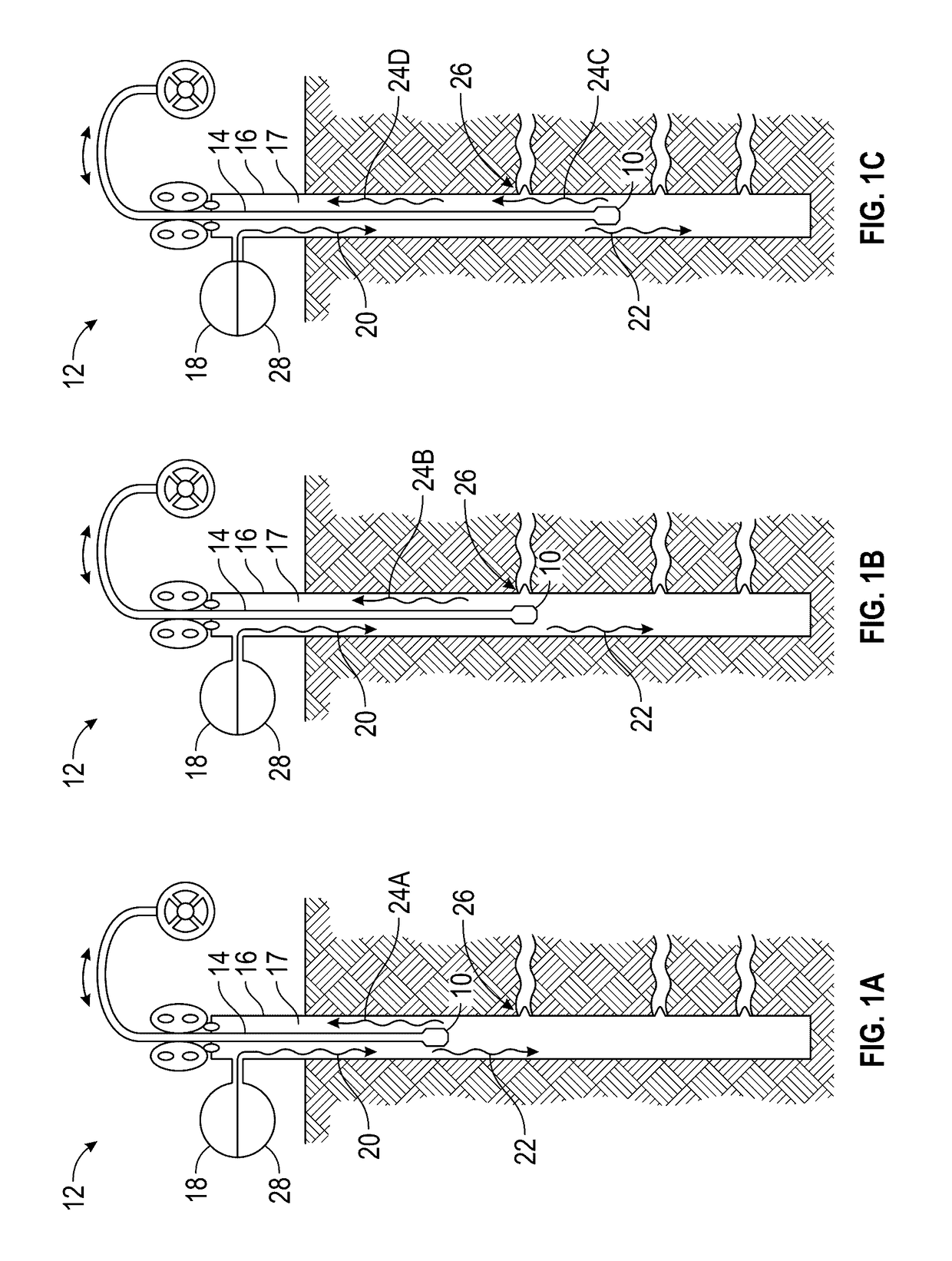

Moving system

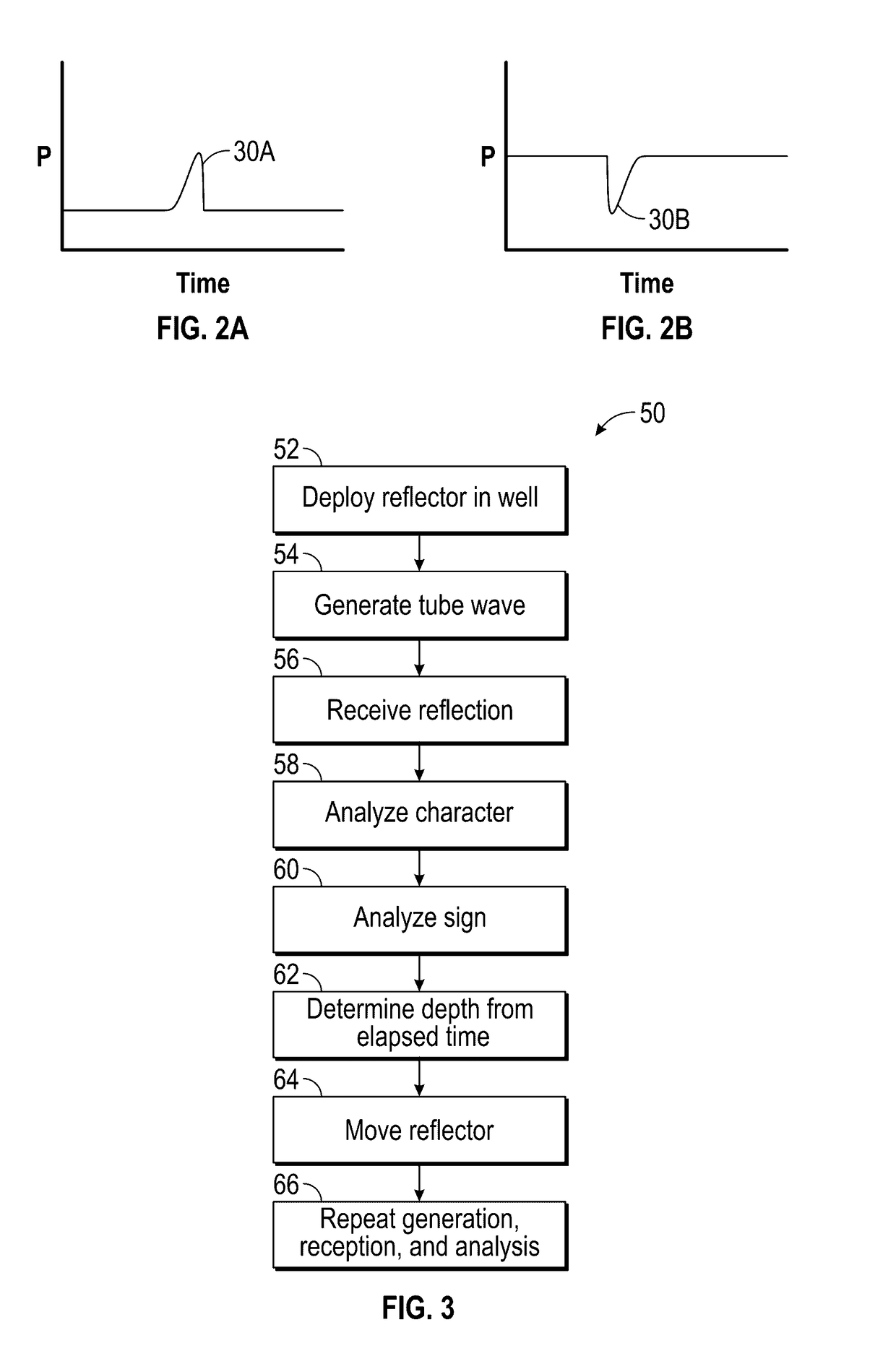

A method moves a tube wave reflector in a well, generates a tube wave, receives a reflection, and determines the depth of one or more reflector locations from the elapsed time. Also, a method to locate a feature in a well deploys a bottom hole assembly (BHA), generates acoustic noise from the BHA, and autocorrelates to determine the BHA depth. Also, a system has a coiled tubing string to a BHA, a surface wave generator, a surface and / or distributed receiver, and a recorder to determine elapsed times between generation and receipt.

Owner:SCHLUMBERGER TECH CORP

Culture method with spatial mixing of aquatic gordon euryale and fishes

InactiveCN107347417AGuaranteed running waterKeep aliveFood processingClimate change adaptationIsosceles trapezoidNutrients substances

The invention discloses a culture method with spatial mixing of aquatic gordon euryale and fishes. The method includes the steps that a fishpond in an inverted isosceles trapezoid shape is arranged, a double-layer net is arranged around the fishpond, a water heating device and a water temperature control device are arranged, and water injection ports and water drainage ports are formed in the four corners of the fishpond; after the dried fishpond is desilted and exposed to the blazing sun for a long time, gordon euryale seeds are sprouted in air without soil, then sowing is conducted, and then water is injected along with early-stage growth of gordon euryale; after water culture, fry are put in, and the fry are fed with feed; disinfection devices are arranged on the water injection ports, compound bacteria and compound sodium nitrophenolate are splashed, and the fishpond is disinfected after harvesting and catching. Fishes cultured through the method grow fast, and meanwhile the natural flavor is maintained; by utilizing photosynthesis, planted gordon euryale absorbs nutrient substances such as nitrogen and phosphorus in water in the fishpond through the developed roots, and produced stems and fruits can be used and have economic benefits.

Owner:安徽舒城万佛湖渔业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com