Method for improving nitrogen yield of air separation device

An air separation unit, nitrogen technology, applied in the direction of cold treatment separation, liquefaction, solidification, etc., can solve the problem of unable to meet the demand for nitrogen, and achieve the effect of ensuring safe and stable operation, low implementation cost, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

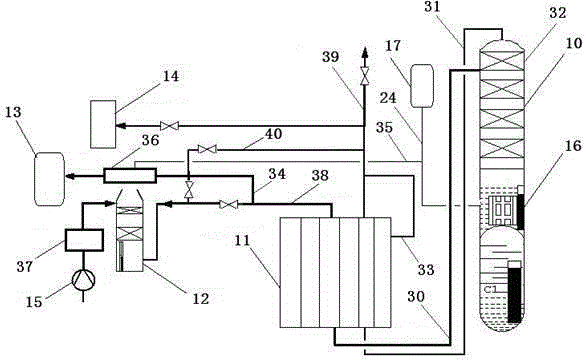

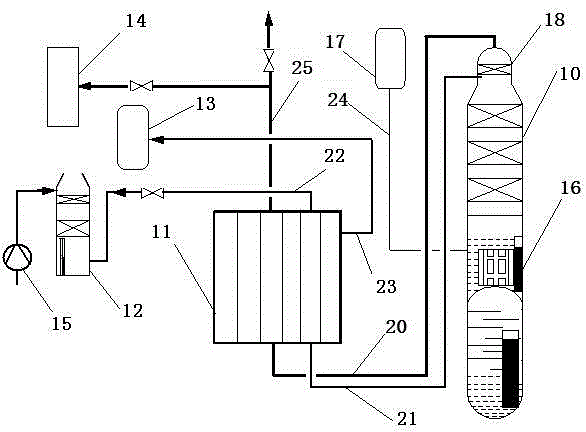

[0022] Below in conjunction with accompanying drawing and the specific embodiment of the present invention, a kind of method of improving the nitrogen output of air separation unit of the present invention is described as follows. In this embodiment, only the process flow and equipment related to the present invention are described as follows.

[0023] figure 1 It is a schematic diagram of the process flow diagram of nitrogen and polluted nitrogen, which is the prior art product of the air separation unit 30,000 oxygen generators of the embodiment.

[0024] The existing conventional design scheme of the 30,000 oxygen generators in this embodiment is: the output of product oxygen and nitrogen is 35000 m 3 / h, wherein the impurity content of product nitrogen is less than 10ppm, the purity of polluted nitrogen is ≥96% and less than the purity of pure nitrogen, and the produced polluted nitrogen is about 60000m 3 / h into the water cooling tower as coolant, 40000m 3 / h into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com