Capacitors with high energy storage density and low esr

a technology of energy storage density and capacitors, applied in the field of capacitors with high energy storage density and low esr, can solve the problems of reducing the efficiency of the production process, reducing so as to reduce the impact of performance or subsequent packaging process flow, and reduce the cost of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

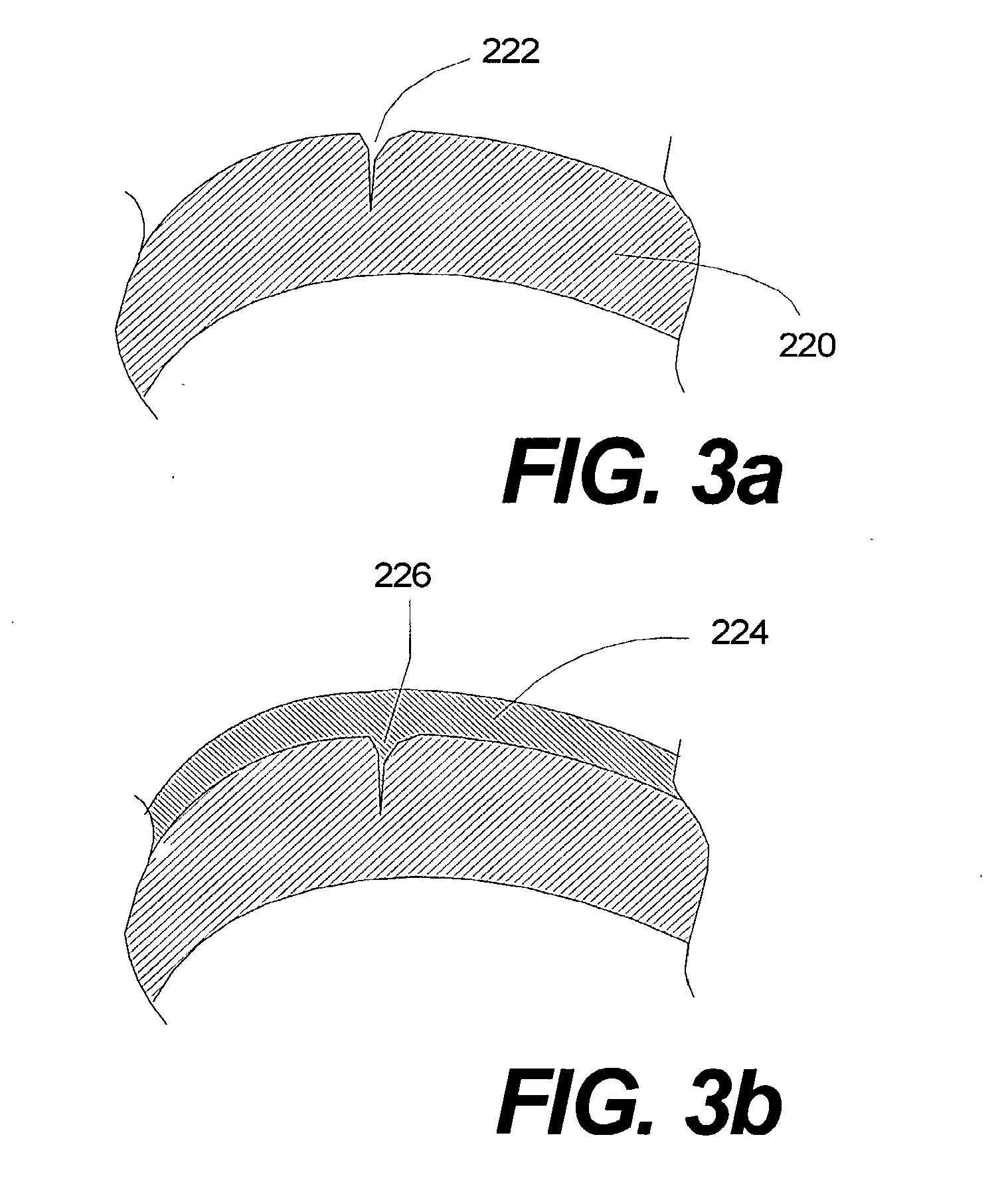

embodiment 450

[0063]While the capacitor layout described in reference to FIG. 6a is suitable for low ESR applications, further improvements are obtained by the implementation of thick overlaying films in contact with layer 406. This embodiment further reduces series resistance related to the non-contact fraction of the area 424. The embodiment 450 is illustrated in FIG. 6b. Film 458 is preferably formed over contact layer 406′ without ambient exposure to avoid surface oxidation of layer 406′. For example, layer 458 is formed by sputtering 0.5 μm to 1 μm of aluminum as known to those who are skilled in the art. While this technique achieves substantially higher contact area through fractional area 424′, it is not required to substantially penetrate into the deep high-capacitance area features such as 422′. In some embodiments, film 458 completely replaces foil 408 (FIG. 6a). In most common applications, relatively thin film 458 is implemented with or without a complementary non-oxidizing film at t...

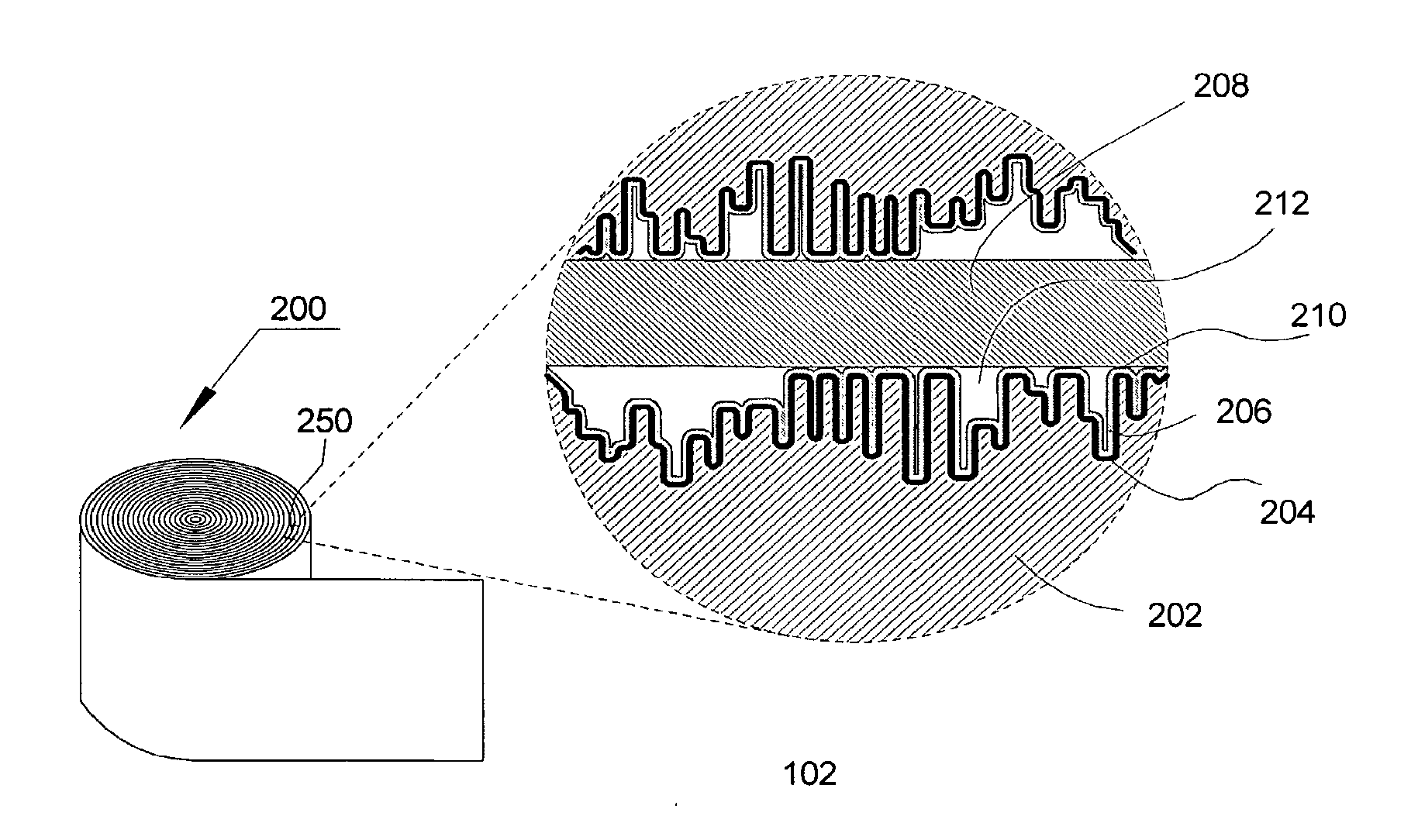

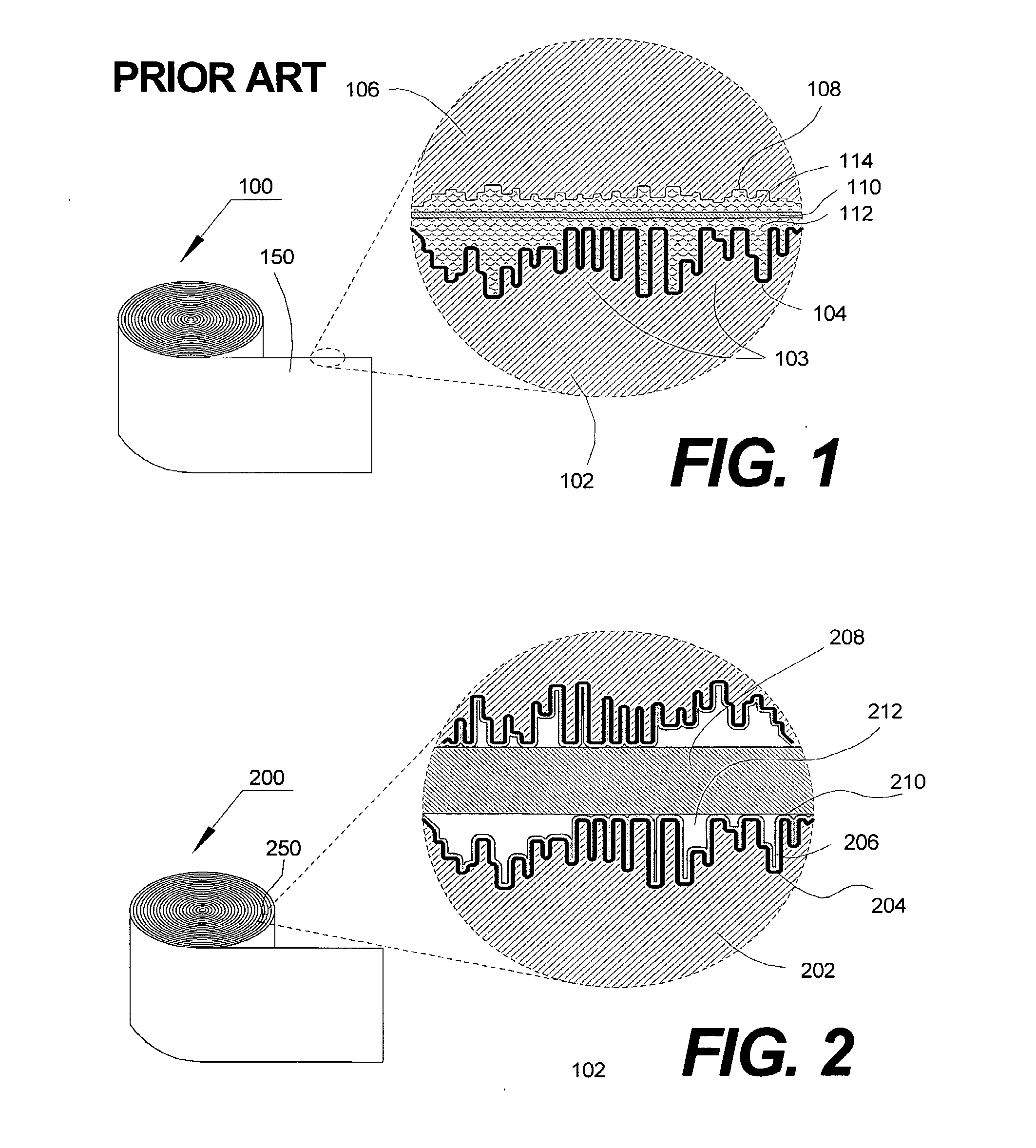

embodiment 1000

[0078]An objective of this invention is to fabricate high-energy storage capacitors. Advantageously, capacitors that are suitable for high voltage are fabricated over aluminum foils with lower area enhancement foil. For example, 50 μm foils with an etched ×40 area enhancement can accommodate a 1.0 μm thick Al2O3 dielectric layer grown on both sides of the foil by ALD or combination of anodic-oxidation and ALD as described above. Derated at 50%, these dielectric films are suitable for the fabrication of 500V capacitors. Low ESR contact is established, for example, by implementing a 50 nm TiN contact layer deposited by ALD followed by 0.5 μm of copper deposited by a combination of 10 nm seed ALD layer and electroplating and by utilizing a commercially available 5.8 μm thick aluminum foil 208 (FIG. 2). Accordingly, capacitance per area is 0.56 μF / cm2. The thickness of the stack is ˜56 μm and the weight per area is 0.01 gram / cm2. A capacitor with 400 μF is formed by winding 1 cm wide st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com