Dielectric composite material comprising benzocyclobutene which contains a filler in order to decrease the coefficient of thermal expansion.

A composite material, phencyclobutene technology, applied in the direction of circuit substrate materials, circuits, printed circuits, etc., can solve problems such as wafer or substrate bending, wafer/substrate cannot be handled, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

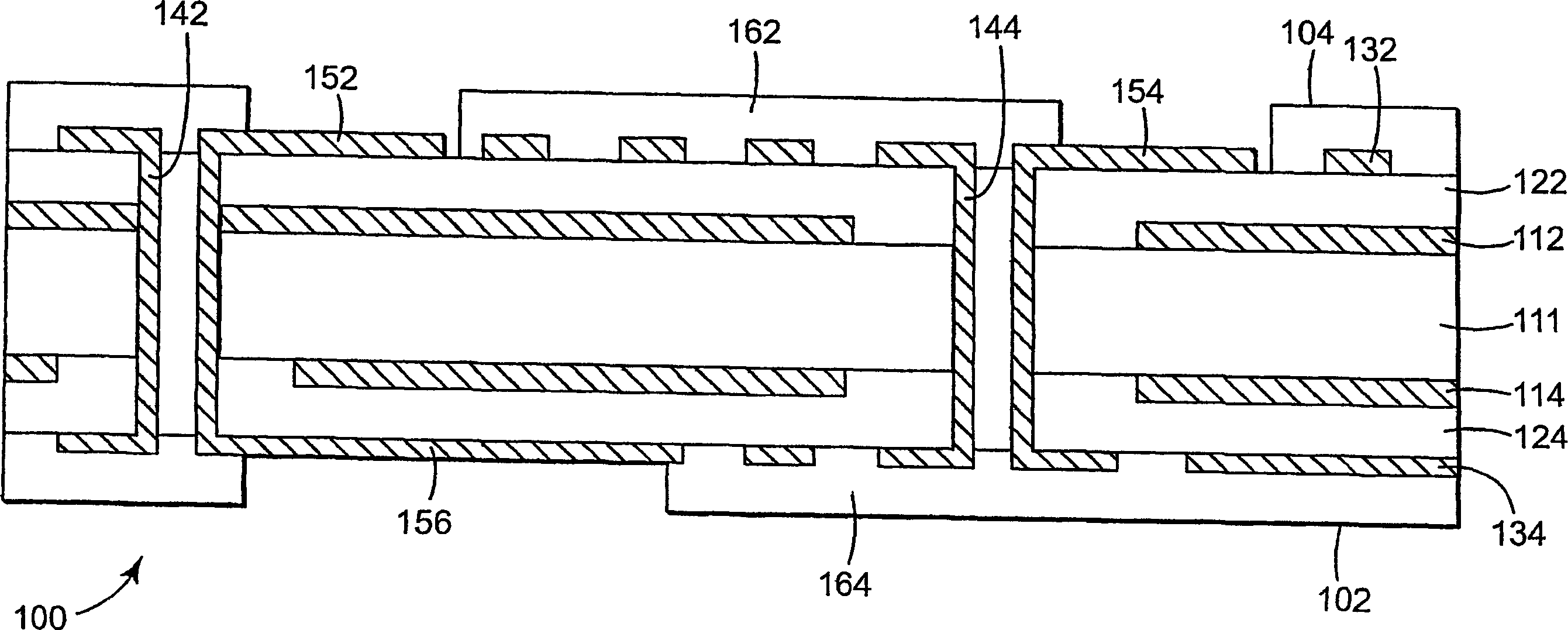

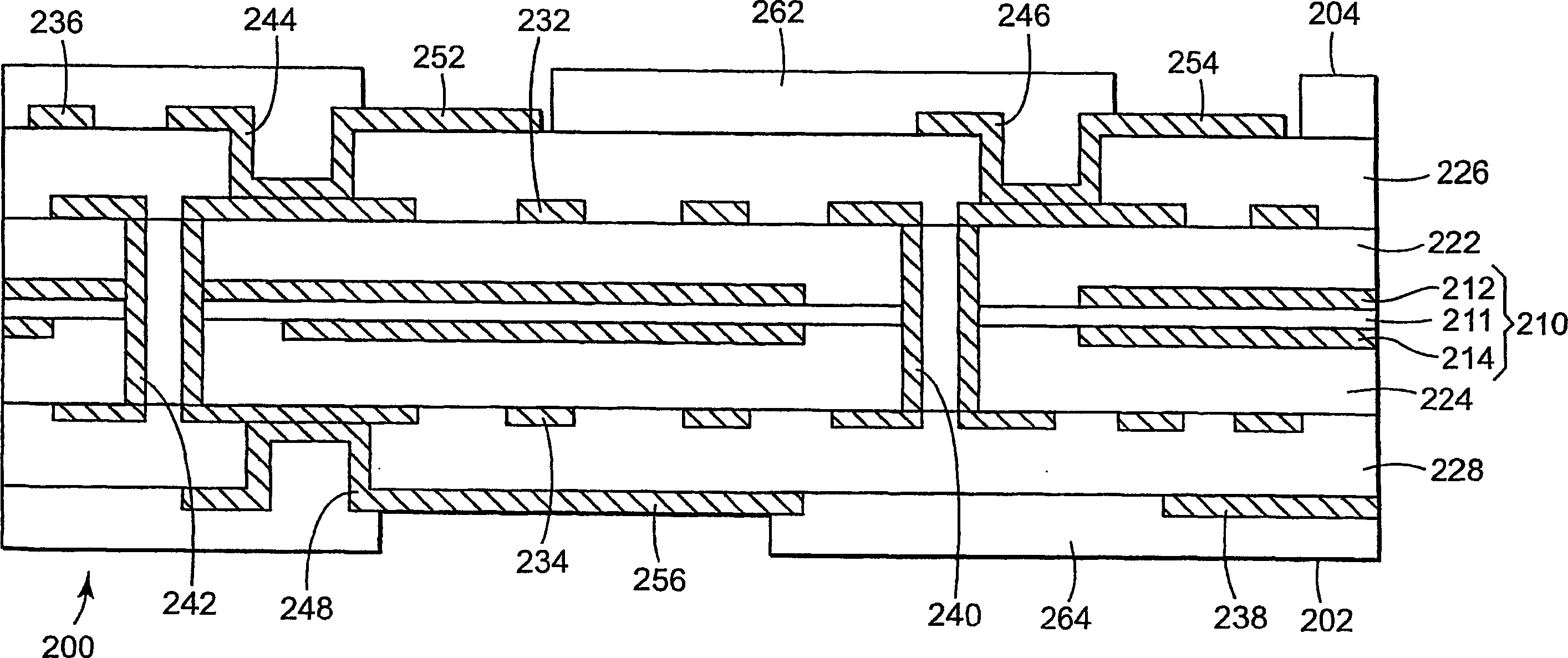

[0028] The dielectric composite of the present invention is a highly filled tough benzocyclobutene (BCB) resin. BCB resins are commercially available from Dow Chemical under the trademark CYCLOTENE. BCB polymers have excellent dielectric properties, including dielectric constant and loss, and can go well into the higher frequency range (1-40GHz) even under high-humidity operating conditions. One example of the protocol described here uses prepolymerized, or "b-staged," divinylsiloxane diphenylcyclobutene, which is commercially available from Dow Chemical Company.

[0029] In order to provide advanced dielectrics for multilayer electronic packaging applications and to meet all the requirements required for advanced dielectric materials, highly filled dielectric polymer composites are formed based on tough benzocyclobutene (BCB) and inorganic filler particles . Tough BCB materials exhibit much improved mechanical properties and can be stretched up to about 35% without macrosco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com