Single-mode high-power vertical cavity surface emitting laser and manufacturing method thereof

A technology of vertical cavity surface emission and manufacturing method, which is applied in the field of structure and production of vertical cavity surface emitting lasers, can solve the problem of low output power of photonic crystal VCSEL, achieve improved thermal characteristics, increase oxidation aperture, and increase single-mode output The effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

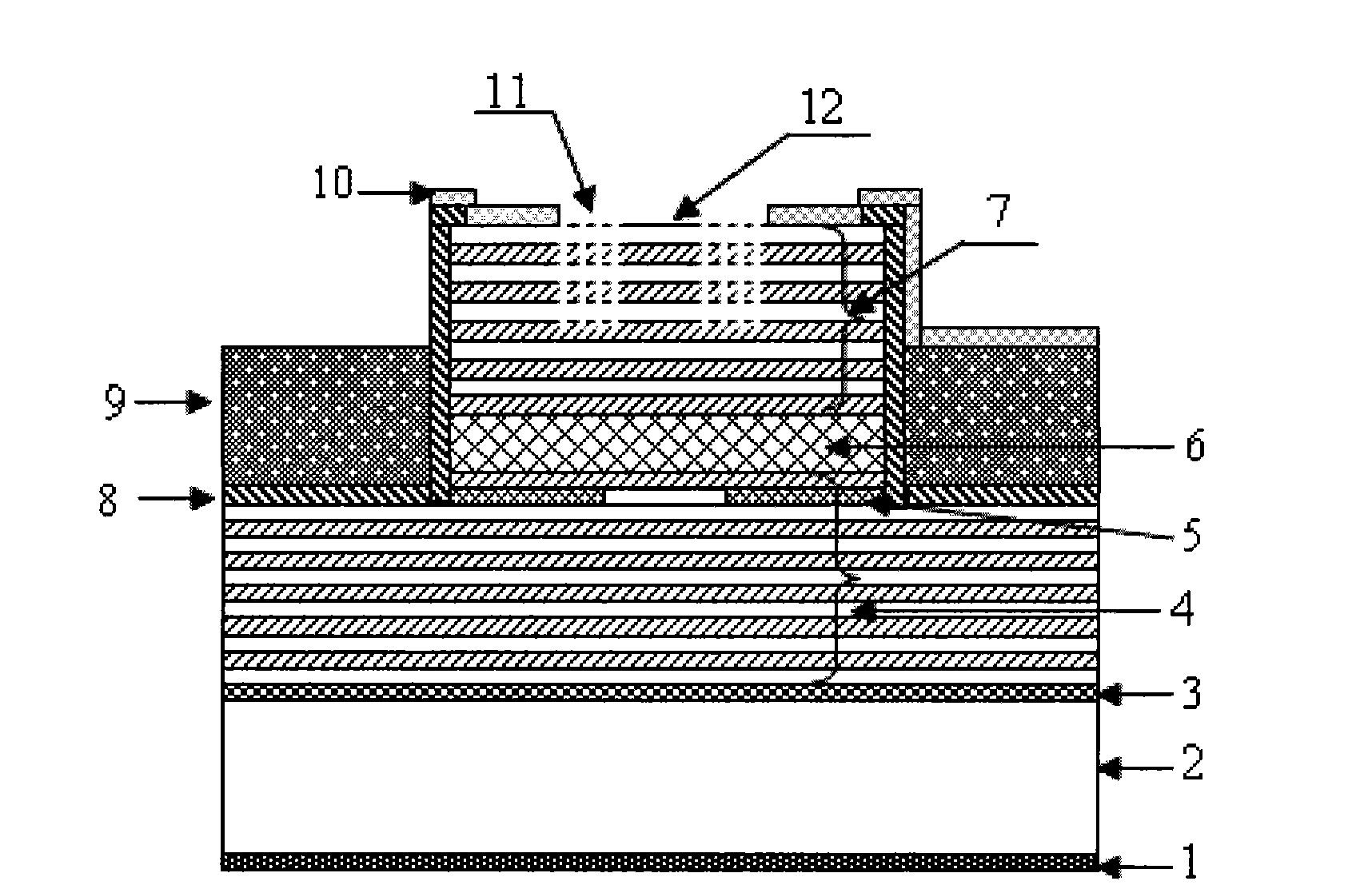

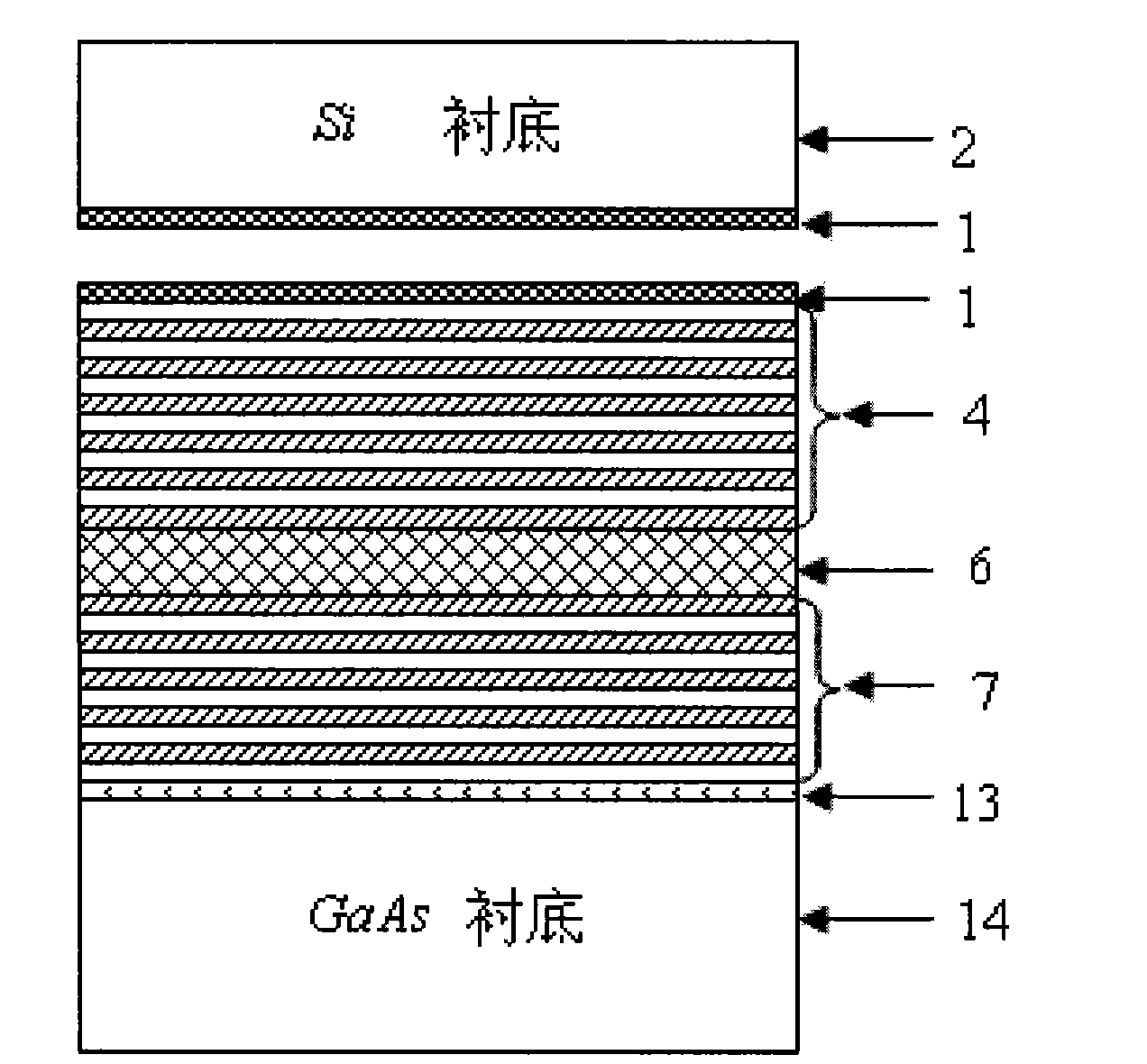

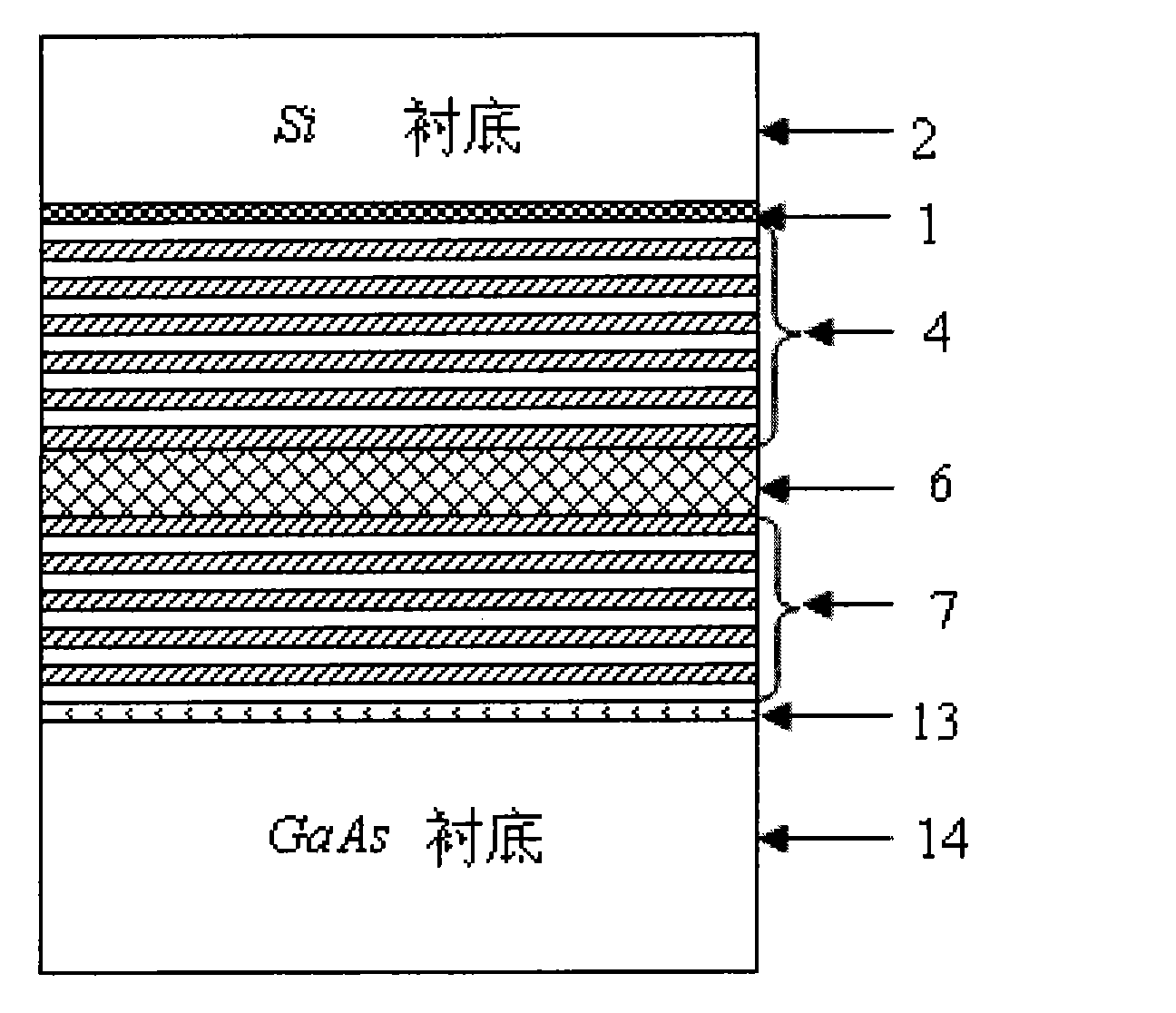

[0034] Embodiment 1: P-type electrode 1 is TiAu, P-type electrode 1 is made on the back side of Si substrate 2, P-type Si substrate 2, metal bond layer 3 is TiAu / Sn / AuTi, by metal bond layer 3 Si substrate 2 and P-type distributed Bragg reflector (DBR) 4 are bonded together, P-type distributed Bragg reflector (DBR) 4, 28 periodic modulation doping and composition gradient Ga0.1Al0.9As / Al0. Alternate composition of 9Ga0.1As material, connected with the active region 6 that can provide gain, used to provide high reflectivity, and at the same time form a current injection channel, P-type DBR4 contains a layer of high aluminum composition near the active region The oxidation confinement layer 5 is used to form electro-optic confinement. The active region 6 is sandwiched between P-type DBR4 and N-type DBR7 to provide optical gain. The active region 6 is composed of three AlInGaAs quantum wells, and the thickness of the active region is is 1λ, λ is the lasing wavelength, N-type DBR7...

Embodiment 2

[0048] Embodiment 2: single-mode high-power VCSEL with a wavelength of 980nm, the middle multi-quantum well active region 7 is made of InGaAs / GaAs material, and the N-type DBR7 and P-type DBR4 are respectively modulated and doped with gradually changing composition GaAs / Al 0.9 Ga 0.1 As, other components are the same as in Embodiment 1.

Embodiment 3

[0049] Embodiment 3: a single-mode high-power VCSEL with a wavelength of 1310nm, the middle multi-quantum well active region 6, adopts GaInNAs / GaAs, or quantum dot materials, N-type DBR7 and P-type DBR4 respectively adopt modulation doping and composition gradient GaAs / Al 0.9 Ga 0.1 As material, other parts are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com