Low temperature airtightness packaging method for wafer level micro machinery device and photoelectric device

A technology for micromechanical devices and optoelectronic devices, applied in metal processing mechanical parts, optomechanical equipment, microstructure devices, etc., can solve the problems of heavy metal pollution in CMOS circuits, difficulty in obtaining large-area bonding, and high bonding temperature of hard solders. Achieve the effect of reducing residual thermal stress, improving process compatibility and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

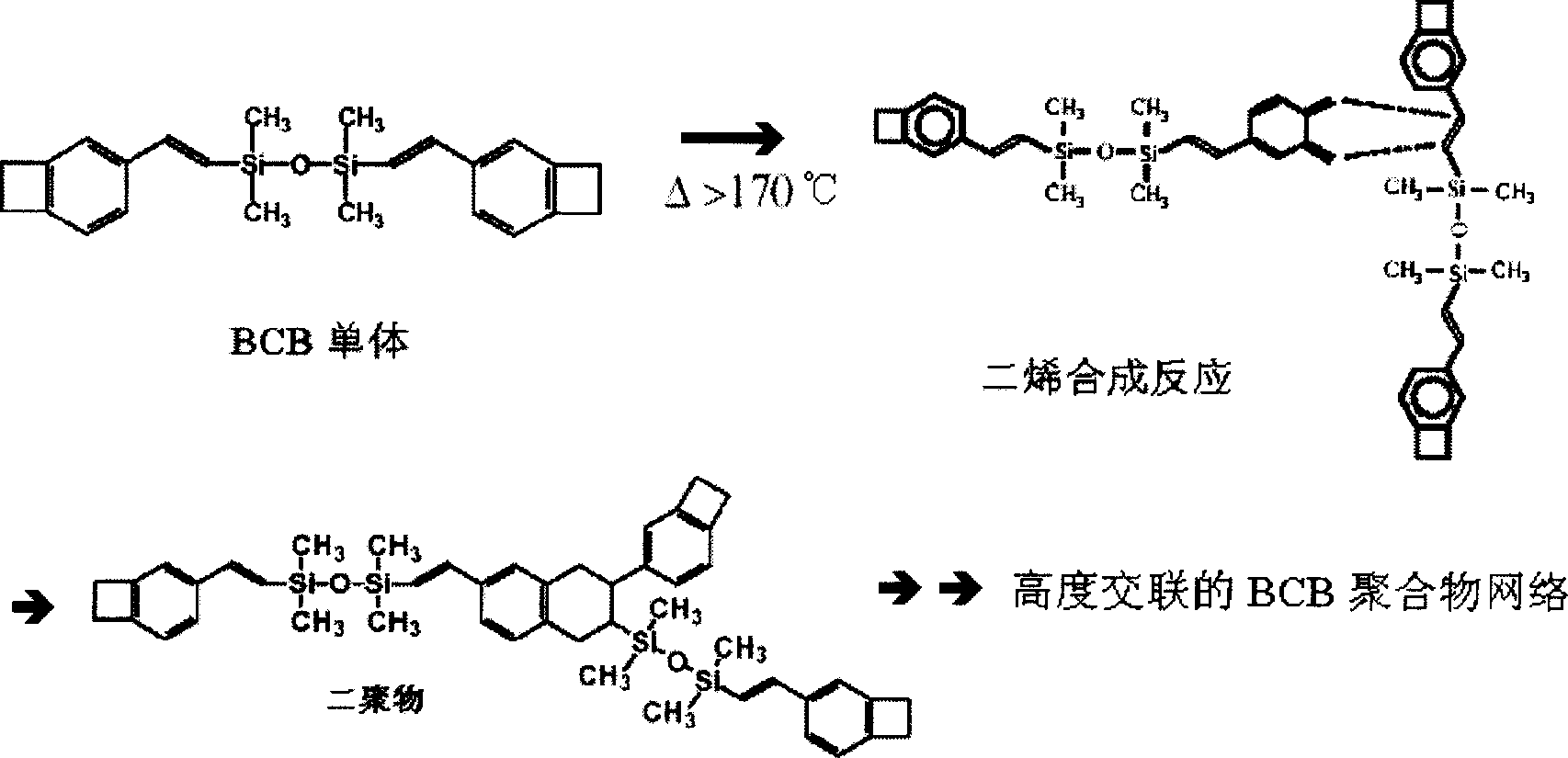

Method used

Image

Examples

Embodiment 1:MEMS( and other approach ), specific pic 5。 Embodiment approach

[0071] Embodiment 1: Carry out low-temperature wafer-level airtight packaging to resonant MEMS devices (comprising resonant beam type and other modes of resonant devices), the specific process flow is as follows Figure 5 shown. The implementation method is as follows:

[0072] (1) Select a semiconductor material such as silicon wafer 1 (ordinary N-type (100) double-polished silicon wafer, thickness 420±15 μm, resistivity 3-8 (Ω cm)), and oxidize to obtain the top mask silicon dioxide 2 and underlying silica 3, such as Figure 5 (b).

[0073] (2) apply photoresist 4 (in this experiment, adopt the trade mark 1912 type photoresist of Shipley Company), and pattern exposure, development, obtain such as Figure 5 (d) structure, forming a mask for the opening of the top layer of silicon dioxide 2 .

[0074] (3) corrode top layer mask silicon dioxide 2 in BOE etching solution, open etching window for it, remove photoresist 4 subsequently, as Figure 5 (f).

[0075] (4) In KOH o...

Embodiment 2

[0079] Embodiment 2: low-temperature wafer-level airtight packaging is carried out to micro-accelerometer devices (comprising small-range high-precision accelerometers, high-range accelerometers, micro-accelerometers moving in the vertical direction, and horizontally sliding micro-accelerometers), specifically The implementation method refers to steps (1) to (7) in Example 1, except that the resonant micromechanical movable part in the cavity is replaced by the micro accelerometer movable part 7 .

Embodiment 3

[0080] Embodiment 3: Carry out low-temperature wafer-level hermetic packaging of micro-gyro devices (including micro-gyro devices such as micro-mechanical capacitive and piezo-resistive types), and the specific implementation method refers to the steps in embodiment 1: (1)~(7) , just replace the resonant micromechanical movable part in the cavity with the microgyro movable part 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com