Benzocyclobutene substituted annular siloxane monomer as well as preparation method and application of benzocyclobutene substituted cyclic annular siloxane monomer

A technology of benzocyclobutene and cyclic siloxane, which is applied in the field of microelectronic packaging medium materials, can solve the problems of high curing temperature, poor flatness and high hygroscopicity, and achieves low water absorption, low dielectric constant, short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 Synthesis of cyclotetrasiloxane BCB monomer: 4-bromobenzocyclobutene (15.1g, 0.083mol), tetramethyltetravinylcyclotetrasiloxane (7.05g, 0.02mol), Add triethylamine (15ml), acetonitrile (50ml), palladium acetate (334mg, 1.49mmol) and tris(o-methylphenyl)phosphine (750mg, 2.45mmol) into a 100mL three-necked flask, and rinse with nitrogen at room temperature for 30 Minutes later, heating and stirring were started, and the mixture was refluxed at 85°C for 24 hours. Finish the reaction, cool to room temperature, pour into 150mL 1mol / L hydrochloric acid aqueous solution, extract with 150mL (3*50mL) dichloromethane, wash the organic phase with water (5*150mL) until neutral. Dry over anhydrous magnesium sulfate overnight, filter, and remove the dichloromethane solution to obtain a brown-yellow oil. Silica gel column chromatography purification, eluent: petroleum ether (boiling range 60-90°C) / dichloromethane=10 / 1 (v / v), after vacuum distillation to remove the solvent,...

Embodiment 2

[0024]Example 2 Preparation of cyclotetrasiloxane BCB prepolymer: add the cyclotetrasiloxane BCB monomer (2.43g) synthesized in Example 1 into mesitylene (7.52g) solvent, Reflux at 170° C. for 24 hours, and cool to room temperature to obtain a prepolymer solution that can be directly used for spin coating film formation. Gel permeation chromatography analysis showed that the number average molecular weight of the prepolymer was 3596 g / mol, the weight average molecular weight was 4135 g / mol, and the molecular weight distribution was 1.150.

Embodiment 3

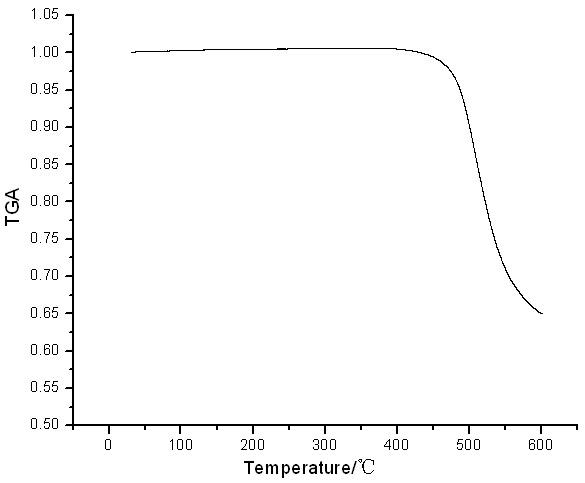

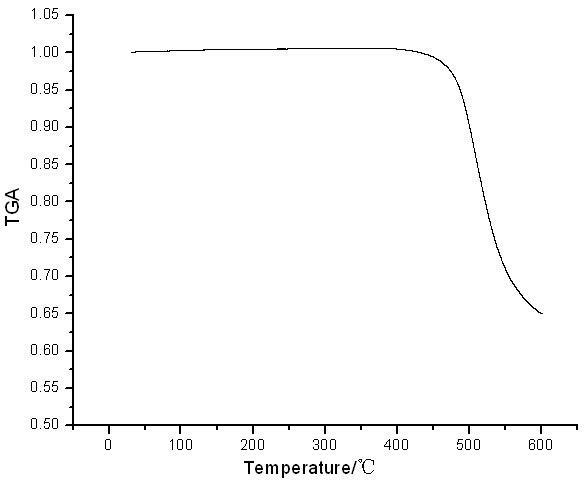

[0025] Example 3 Curing of cyclotetrasiloxane BCB: put the cyclotetrasiloxane BCB synthesized in Example 1 into a specific mold, and react according to the following conditions: 80°C / 1h, 150°C / 1h, 210°C / 1h, 240℃ / 1h, 250℃ / 1h, to obtain a cured resin with mechanical properties without pore distribution. IR(KBr, cm -1 ): 2958(s), 2925(s), 2827(s), 1604(s), 1570(m), 1500(s), 1437(s), 1261(vs), 1059(vs), 788(s ). Thermogravimetric analysis: the initial thermal decomposition temperature (1% weight loss) of the cured product of cyclotetrasiloxane BCB is 487.3°C, and the residual amount at 600°C is 65.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

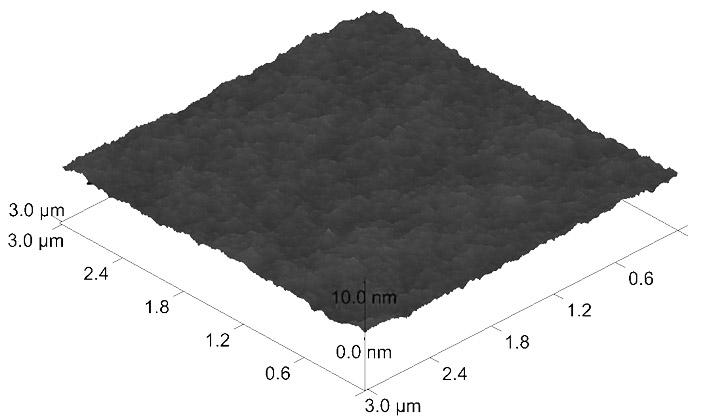

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com