Solid-state imaging device, method for manufacturing the same, and camera using the same

A technology of a solid-state imaging device and a manufacturing method, which is applied in radiation control devices, image communications, televisions, etc., and can solve problems such as the inability to stably form a transmission layer, the inability to fully guarantee the length of an optical path, and the decline in pixel light-gathering efficiency, to achieve the ultimate goal. Optimizing, reducing manufacturing deviation, and high light-gathering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

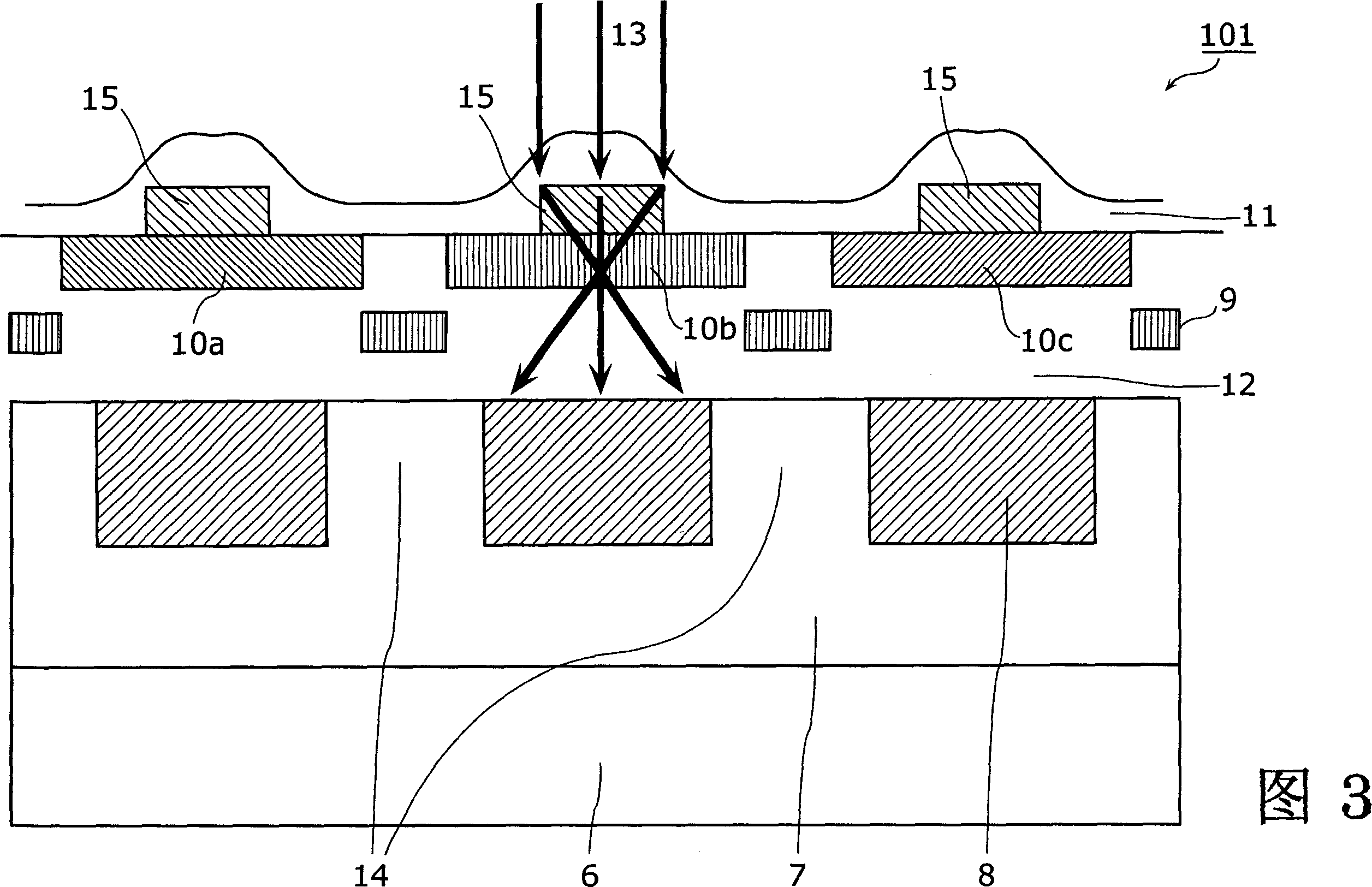

[0087] 3 is a cross-sectional view of a pixel portion of the solid-state imaging device according to the first embodiment of the present invention. In the solid-state imaging device 101 (only three pixels are shown) shown in FIG. 3 , a P-type layer 7 is formed on the N-type layer 6 , and a photodiode 8 is formed in the P-type layer 7 . A light shielding film 9 for shielding light is formed above the isolation region 14 for isolating the photodiodes 8 . In addition, an interlayer insulating film 12, color filters 10a to 10c that transmit only the color light corresponding to each pixel, and the vertically-shaped light of the present invention for condensing incident light 13 are formed on the photodiode 8. The transmissive layer 15 and the lens layer 11 having a concavo-convex shape formed on the upper portion and the periphery of the transmissive layer 15 . In addition, the shape of the transmissive layer 15 may be a cuboid, a cylinder, or the like. In addition, the material...

no. 2 Embodiment approach

[0090] 4 is a cross-sectional view of a pixel portion of a solid-state imaging device according to a second embodiment of the present invention. Here, the difference from the first embodiment is that in the solid-state imaging device 102, the width and height of the vertically shaped transmissive layer of the present invention are determined according to various colors of red (R), green (G) and blue (B). The unit pixels corresponding to the colors are optimally changed, correspondingly, the concavo-convex shape of the lens layer 11 is changed, and the focal lengths relative to the light of each color are respectively set to optimal focal lengths. In particular, since the refractive index of the transmissive layer 15 increases on the short wavelength side and conversely decreases on the long wavelength side, it is necessary to adjust the size of the transmissive layer.

[0091] Among the transmissive layers 15a, 15b, and 15c, the transmissive layer 15a has the smallest width an...

no. 3 Embodiment approach

[0093] Figure 5 (a) to (e) are explanatory diagrams of a method of manufacturing the light-condensing element of the solid-state imaging device according to the third embodiment of the present invention.

[0094] First, if Figure 5 As shown in (a), on the upper part of the base 201 (the color filters 10a to 10c in the above-mentioned first and second embodiments), a film containing SiO? The transmissive layer material 202. Secondly, if Figure 5 As shown in (b), a resist film 203 is formed on the top of the transmissive layer material 202, as Figure 5 As shown in (c), the resist film 203 other than the predetermined portion is removed by photolithography. and further as Figure 5 As shown in (d), the transmissive layer material 202 outside the predetermined area is removed by dry etching. Then if Figure 5 As shown in (e), the use viscosity is higher than that of SiO? The material (BPSG film, TEOS film, benzocyclobutene, polyimide resin, etc.) is used to form the lens lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com