Hybrid integrated laser based on BCB (benzocyclobutene) bonding process and manufacturing method thereof

A hybrid integration and bonding process technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of low heat dissipation efficiency and low output power, and achieve the effect of improving heat dissipation efficiency, reducing production costs, and being easy to package.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Such as Figure 1~Figure 11 As shown, the present embodiment provides a method for manufacturing a hybrid integrated laser based on a BCB bonding process, and the method at least includes the following steps:

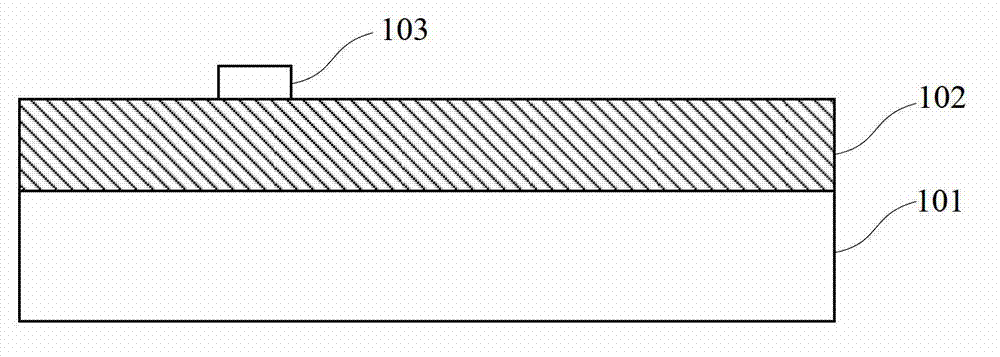

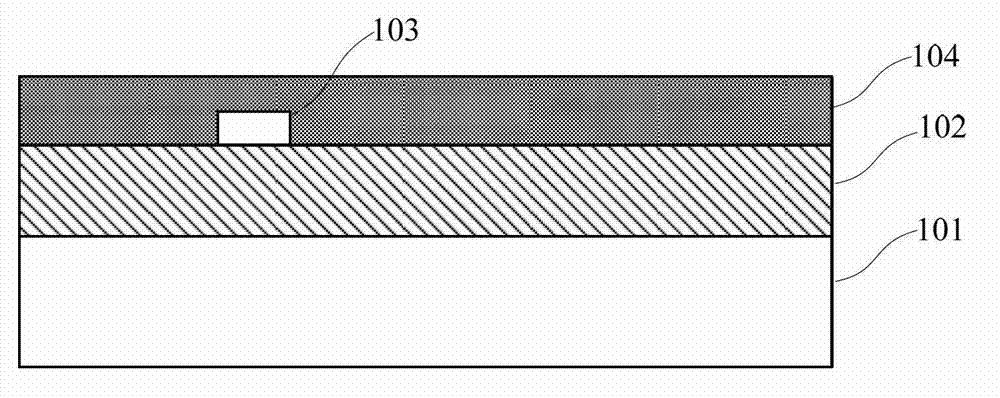

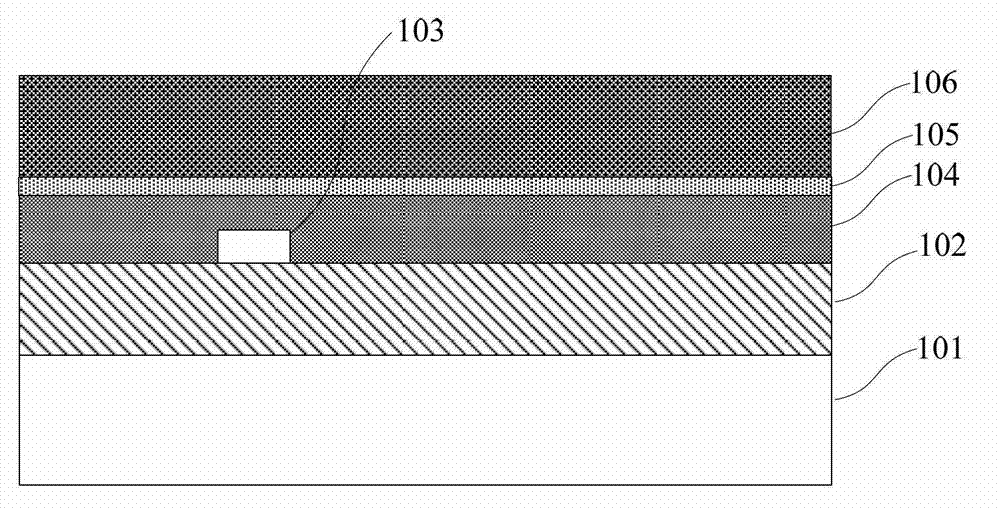

[0061] Such as Figure 1~Figure 3 As shown, step 1) is first performed, providing an SOI-based optical waveguide chip including a silicon substrate 101, a buried oxide layer 102, and a silicon waveguide structure 103, and a bottom contact layer 105, an active layer, a tunnel junction, and a top contact layer. Group III-V laser epitaxial layers 105-106, form a BCB cladding layer on the surface of the SOI-based optical waveguide chip, and bond the SOI optical waveguide chip and the III-V group laser epitaxial layer through the BCB cladding layer 104 Layer 105~106.

[0062] The silicon waveguide structure 103 is a strip-shaped silicon waveguide structure 103, and the strip-shaped silicon waveguide structure 103 may be, but not limited to, a linear strip-shaped sili...

Embodiment 2

[0071] Such as Figure 11 As shown, this embodiment provides a hybrid integrated laser based on BCB bonding process, the hybrid integrated laser at least includes:

[0072] SOI-based optical waveguide chip, including a silicon substrate 101, a buried oxide layer 102 bonded to the surface of the silicon substrate 101, and a silicon waveguide structure 103 fabricated on the surface of the buried oxide layer 102;

[0073] BCB cladding layer 104, covering the buried oxide layer 102 and the surface of the silicon waveguide structure 103;

[0074] Group III-V laser epitaxial layers 105-106, including a bottom contact layer 105 bonded to the surface of the BCB cladding layer 104, an active layer partially bonded to the bottom contact layer 105, and a tunnel junction bonded to the active layer and a top contact layer bonded to the tunnel junction;

[0075] The heat sink through hole 108 runs through the III-V laser epitaxial layers 105-106, the BCB cladding layer 104 and the buried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com