Organic-inorganic hybrid integrated polymer variable optical attenuator and preparation method thereof

A hybrid integration and polymer technology, applied in the direction of instruments, optics, nonlinear optics, etc., can solve the problem of high power consumption of VOA, and achieve the effects of fast response, compact structure, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

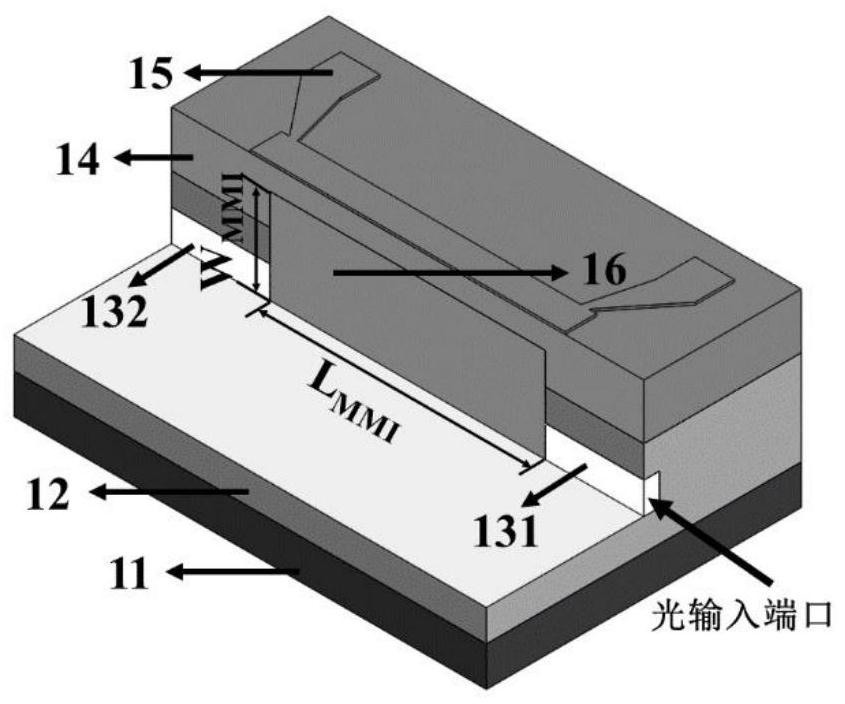

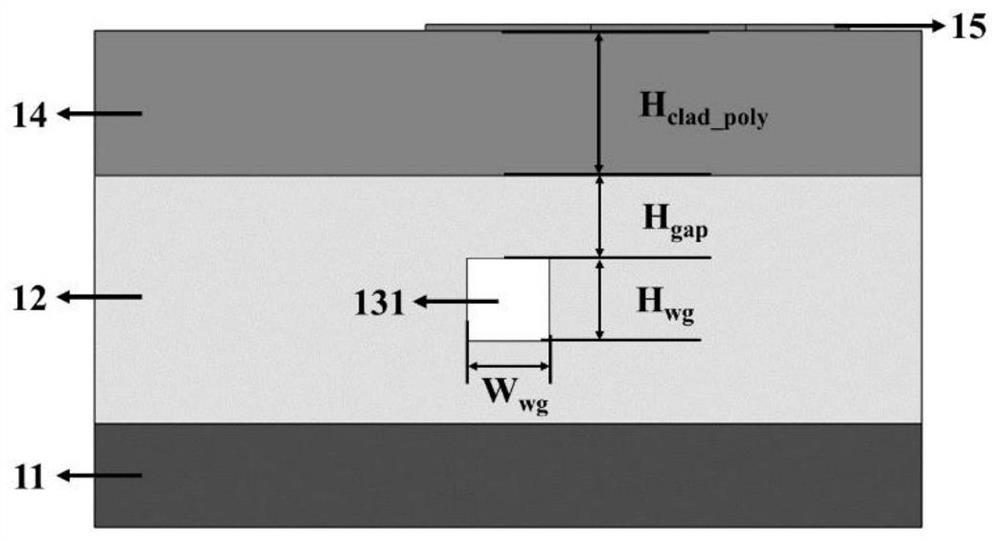

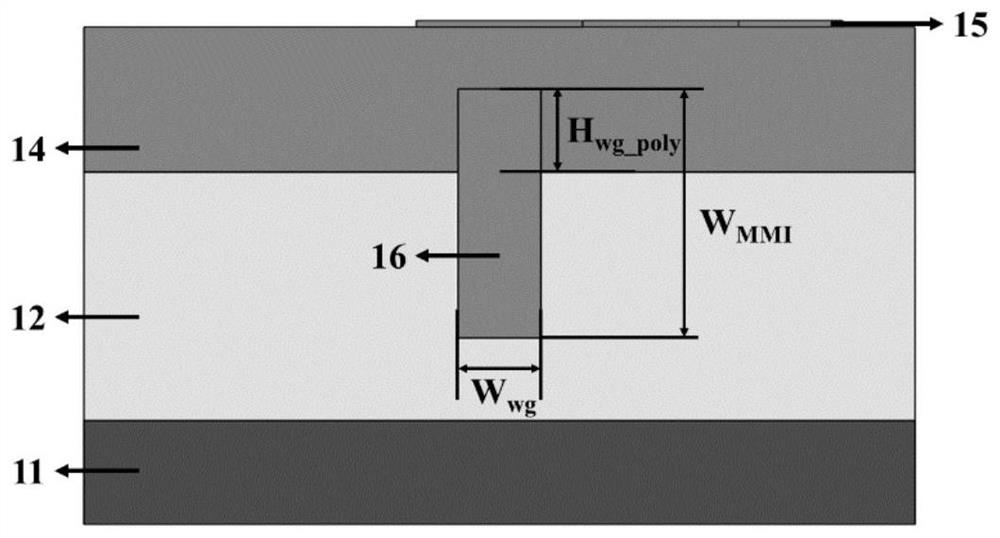

[0041] as attached figure 1 As shown, it is a VOA device based on organic-inorganic hybrid integration of vertical MMI structure. In order to demonstrate the structure of the device, the schematic diagram is partially sectioned to expose the silicon dioxide cladding and polymer core waveguide structure. Wherein the name of each part is: silicon substrate 11, silicon dioxide cladding layer 12, the silicon dioxide core layer waveguide of the strip structure is respectively used as the silicon dioxide input waveguide unit 131 and the silicon dioxide output waveguide unit 132, and the polymer cladding layer 14, metal modulation electrode 15, polymer core waveguide 16.

[0042] The refractive index difference between the cladding layer and the core layer of silicon dioxide is 2%, and the calculation formula is shown in formula (1), wherein the core layer of silicon dioxide is a silicon dioxide material doped with germanium, and the refractive index is n 1 =1.4739; the upper cladd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com