Surface mounting process for flexible circuit board and used magnetic tool and steel mesh

A surface mount technology and flexible circuit board technology, which is applied in the direction of assembling printed circuits with electrical components, can solve problems affecting the quality of the mounting process, affecting the SMT and reflow soldering process, and having too much solder paste to achieve good isolation Thermal effect, saving of tool cost and labor cost, effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

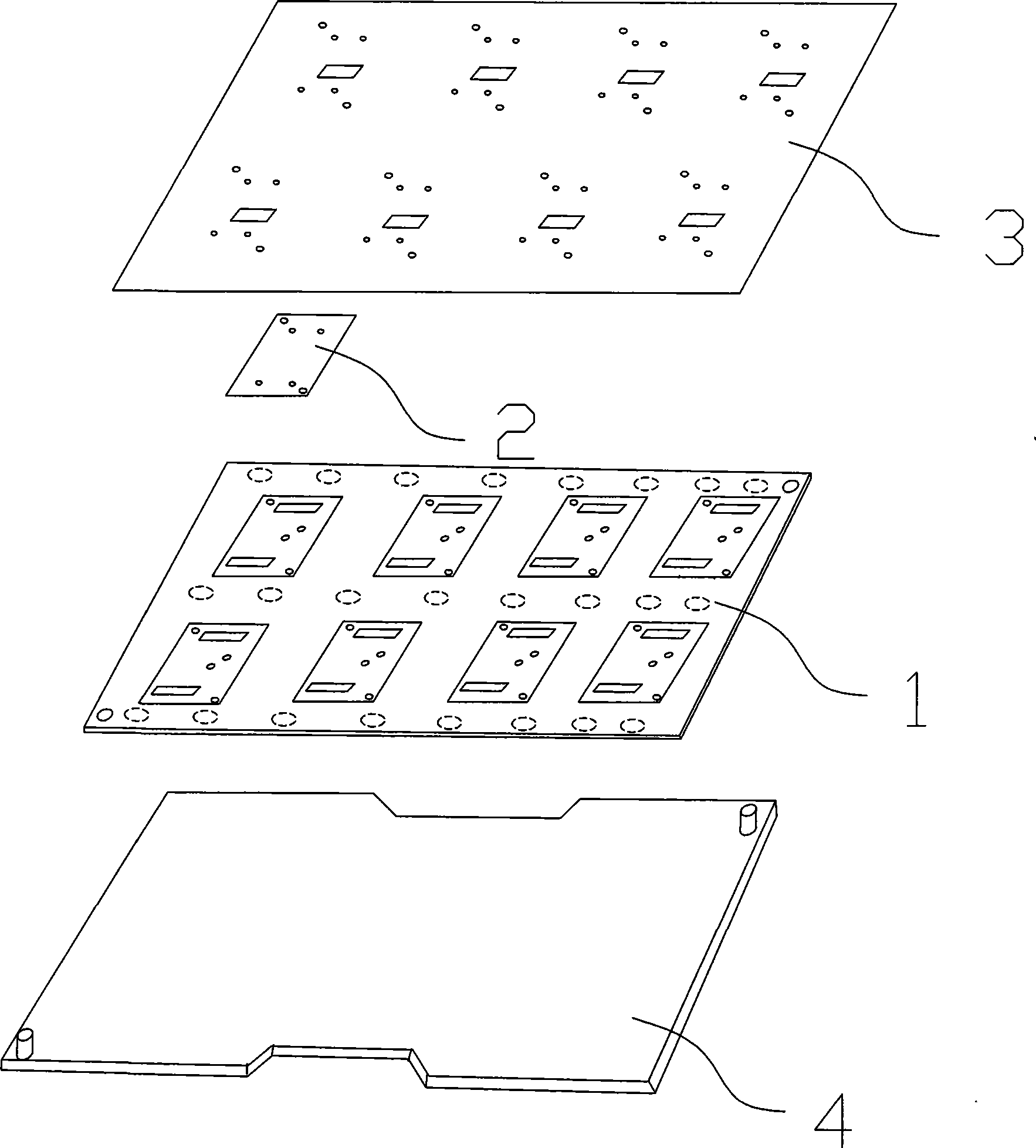

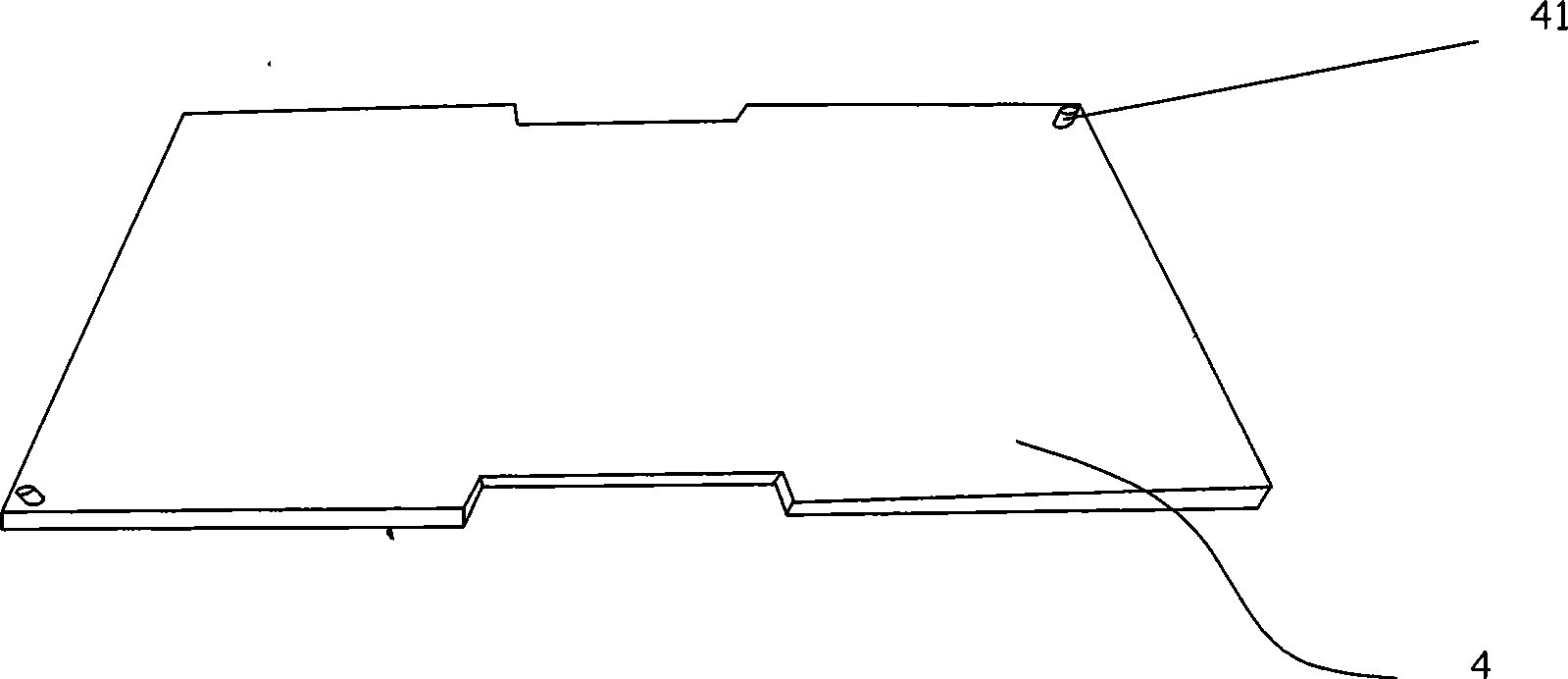

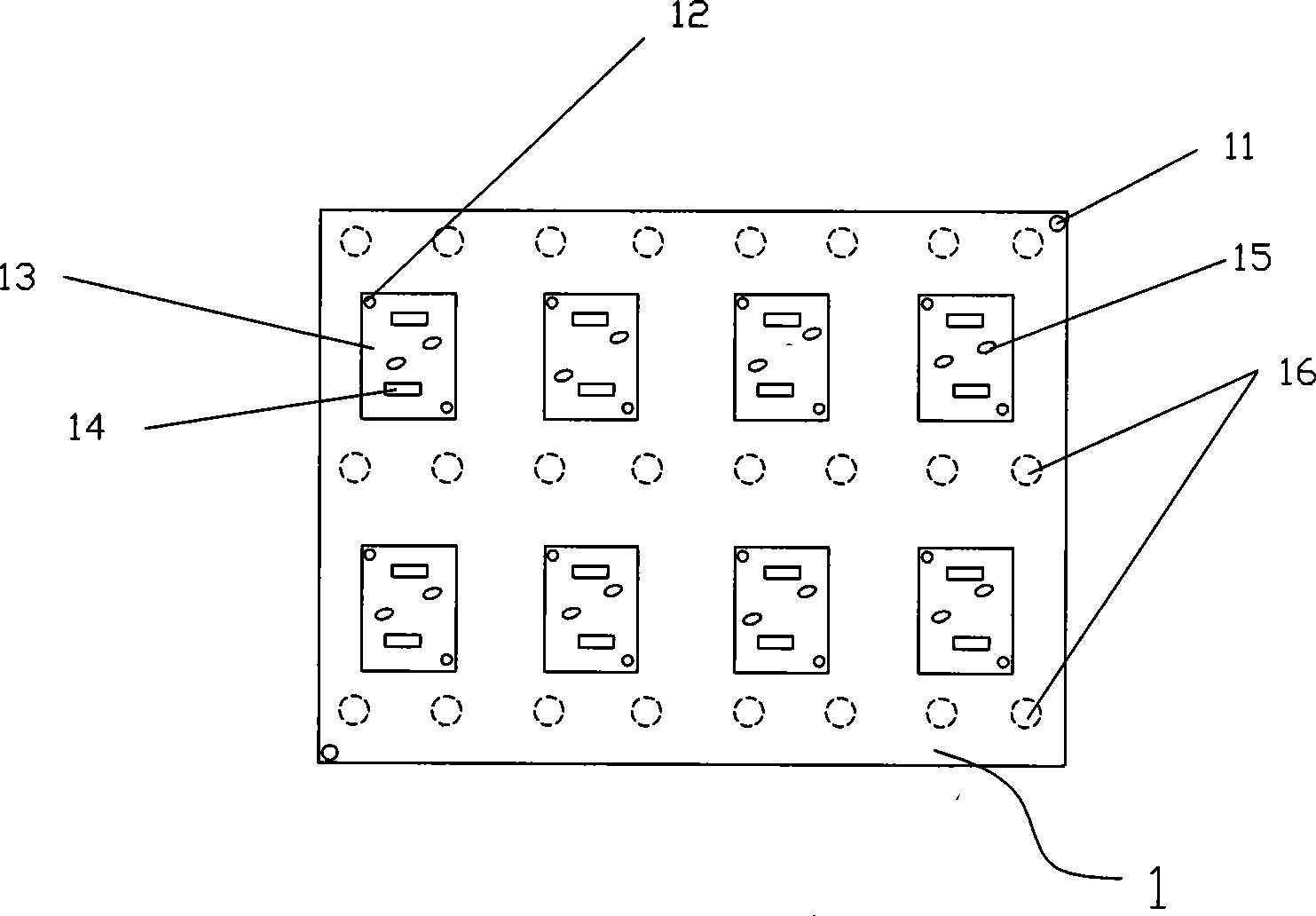

[0041] Such as Figure 1-5 As shown, the magnetic jig involved in the present invention includes a magnetic tray 1, a snap cover 3 and a positioning base 4, and the positioning base 4 is provided with two positioning pins 41 (three or more than three positioning pin); the magnetic tray 1 is made of aluminum alloy blackened and then inlaid with a permanent magnet 16 resistant to a high temperature of 300°C made), the magnetic tray 1 is provided with a base positioning hole 11 corresponding to the base positioning pin 41 and a tray positioning hole 12, and the magnetic tray 1 is also provided with a positioning groove with the same shape as the flexible circuit board 2 13. The groove 14 and the heat dissipation hole 15 corresponding to the position of the components on the circuit board, the groove 14 can be filled with components when the flexible circuit board 2 is mounted on both sides; the press button cover Plate 3 is a stainless steel sheet that can be attracted by a magn...

Embodiment 2

[0050] Such as Figure 1-5 As shown, the magnetic jig involved in the present invention includes a magnetic tray 1, a snap cover 3 and a positioning base 4, and the positioning base 4 is provided with two positioning pins 41 (three or more than three alignment pin); the magnetic tray 1 is made of blackened aluminum alloy and then inlaid with a permanent magnet resistant to 300°C high temperature (also can be made of synthetic stone, high temperature resistant glass fiber and inlaid with a high temperature resistant permanent magnet ), the magnetic tray 1 is provided with a base positioning hole 11 corresponding to the base positioning pin 41 and a tray positioning hole 12, and the magnetic tray 1 is also provided with a positioning groove 13 having the same shape as the flexible circuit board 2 1. The groove 14 and the heat dissipation hole 15 corresponding to the position of the components on the circuit board, the groove 14 can be filled with components when the flexible cir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com