Liquid crystal display device and assembly method thereof

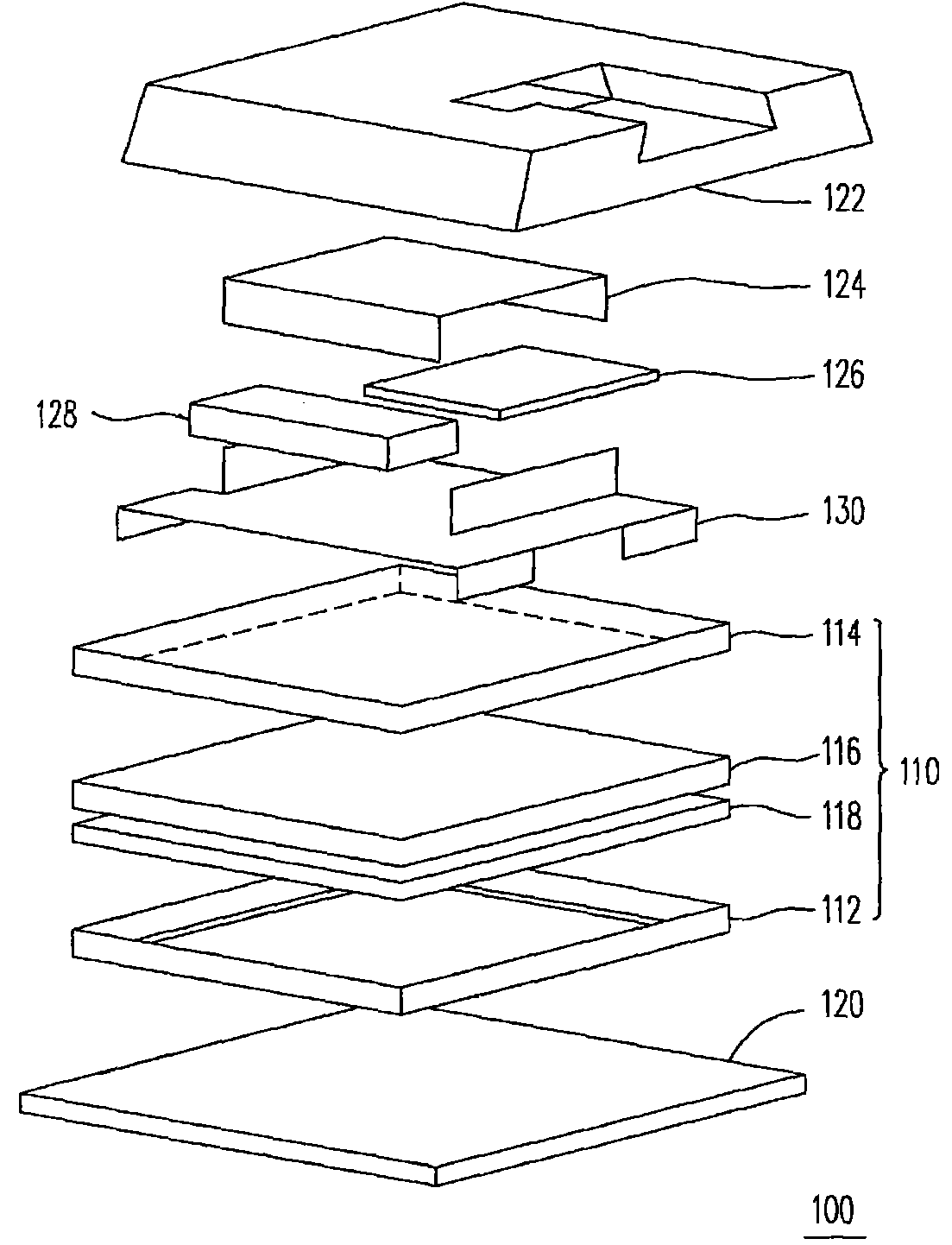

A technology for liquid crystal display devices and display panels, which is applied in the directions of identification devices, nonlinear optics, instruments, etc., and can solve the problems that the assembly efficiency cannot be effectively improved and the assembly cost of the liquid crystal display device 100 cannot be reduced, so as to improve the assembly efficiency and reduce the assembly cost. Cost, the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

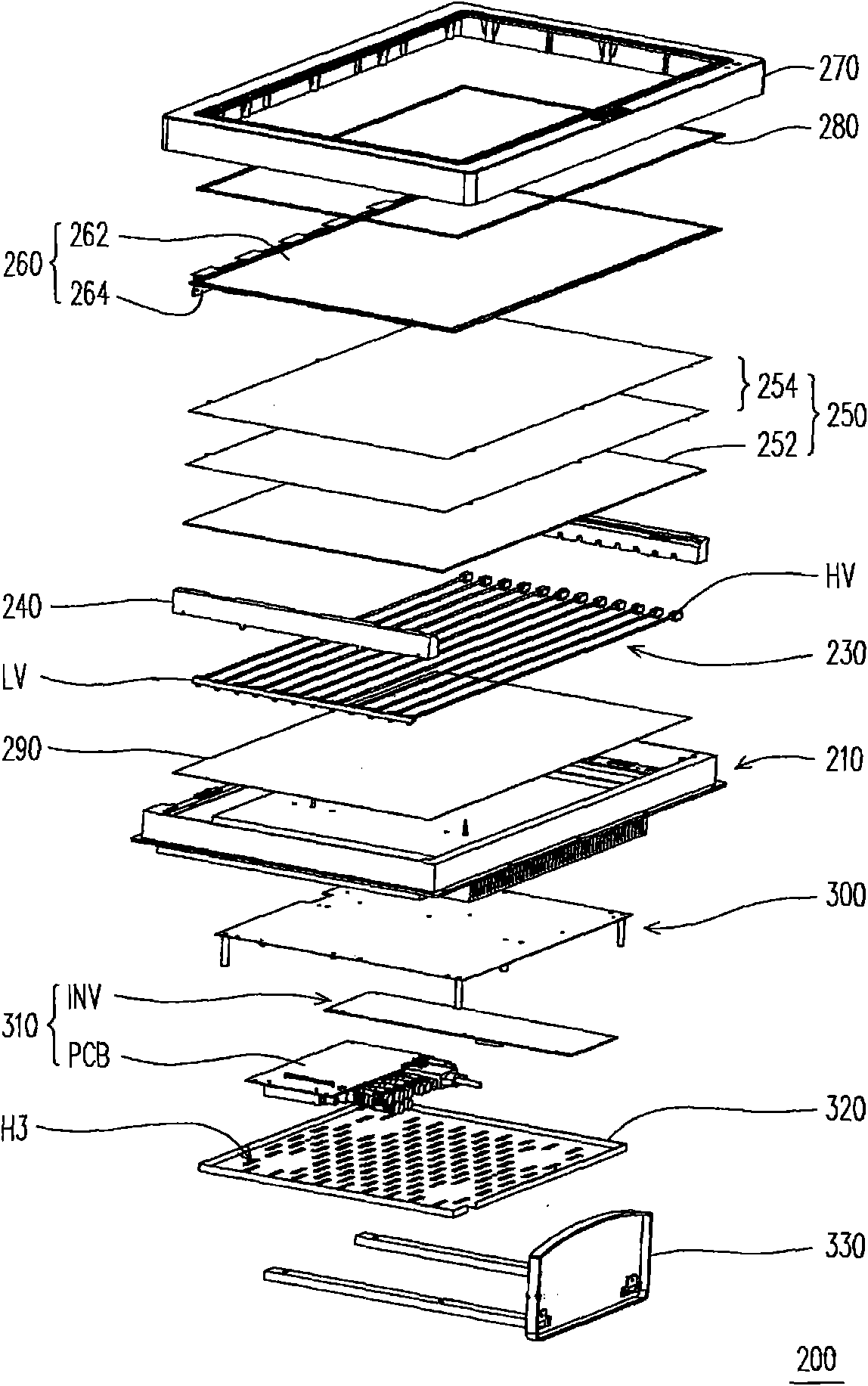

[0107] figure 2 It is an exploded perspective view of a liquid crystal display device according to an embodiment of the present invention. Please refer to figure 2 The liquid crystal display device 200 includes a signal control module 310, a rear cover 210, a plurality of line light sources 230, a pair of carriers 240, a plurality of optical films 250, a display panel 260, a front frame 270, etc. stacked in sequence. member.

[0108] In the liquid crystal display device 200 of this embodiment, the linear light source 230 , the carrier 240 , the optical film 250 , the display panel 260 and the front frame 270 are sequentially assembled on one side of the rear cover 210 . Moreover, the signal control module 310 is disposed on the other side of the rear cover 210 . In addition, the rear cover 210 is, for example, an integrally formed plastic shell. Compared with the traditional liquid crystal display device 100 which requires at least four front frames and rear covers in to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com