One-dimensional contact point positioning method of capacitive touch screen/board and capacitive touch screen/board

A technology of capacitive touch screen and positioning method, applied in the direction of electric digital data processing, input/output process of data processing, instruments, etc., can solve the problems of high production cost, many manufacturing processes, expensive price, etc., and achieve reduction of production cost and reduction The effect of material consumption and simplification of production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

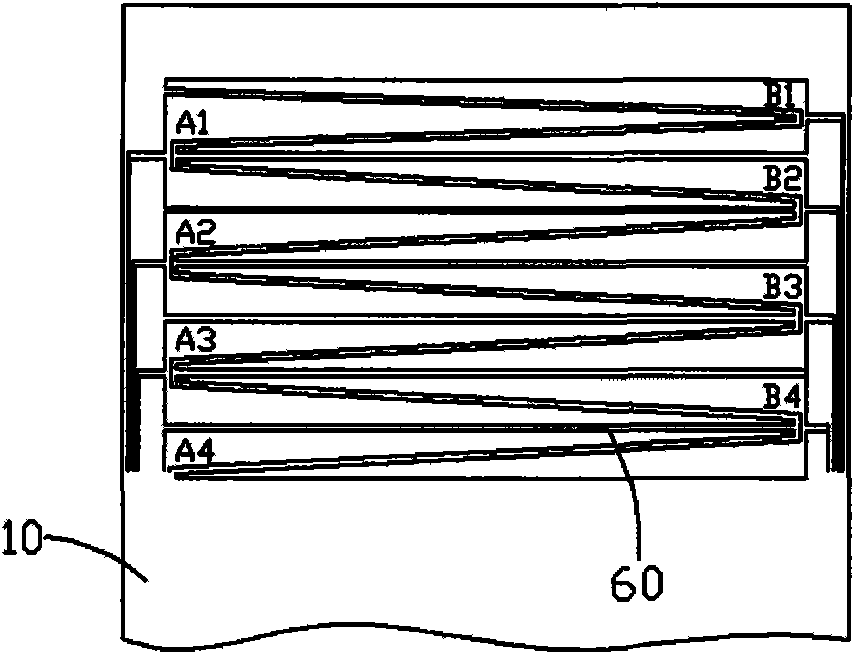

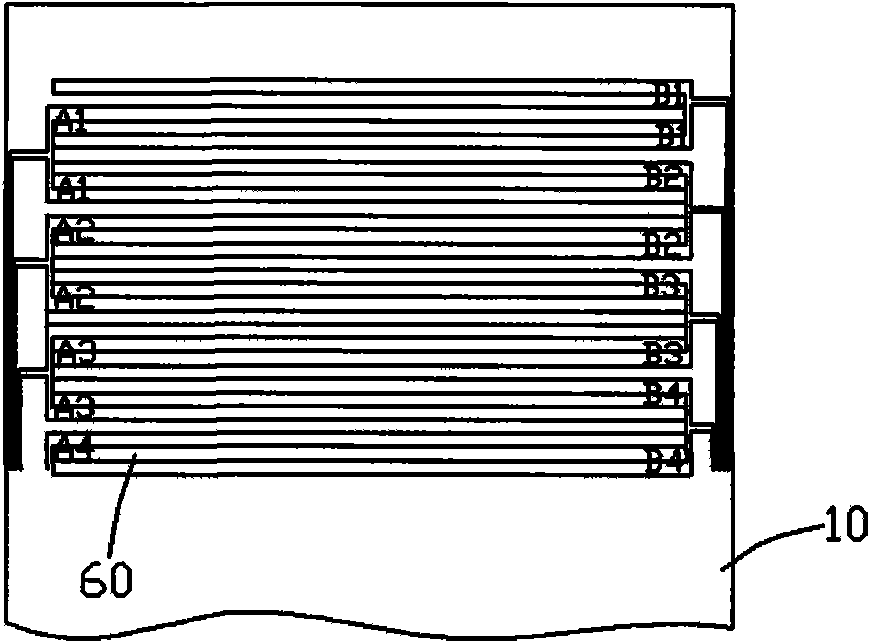

[0016] The one-dimensional contact positioning method of the capacitive touch screen / board of the present invention is to arrange a single-layer ITO line on the substrate, and each ITO line of the ITO line has a certain capacitance value, and forms an interactive cross arrangement, but is not electrically connected. Graphics; when a finger touches the display screen, the touch IC first determines the position of the touch point in the Y-axis direction according to whether the total capacitance value of the multiple ITO lines touched by the finger changes, and then, according to the capacitance value of each line accounted for by the finger touch The determined ratio of the total capacitance of the ITO line is used to determine the position of the touch point in the X-axis direction.

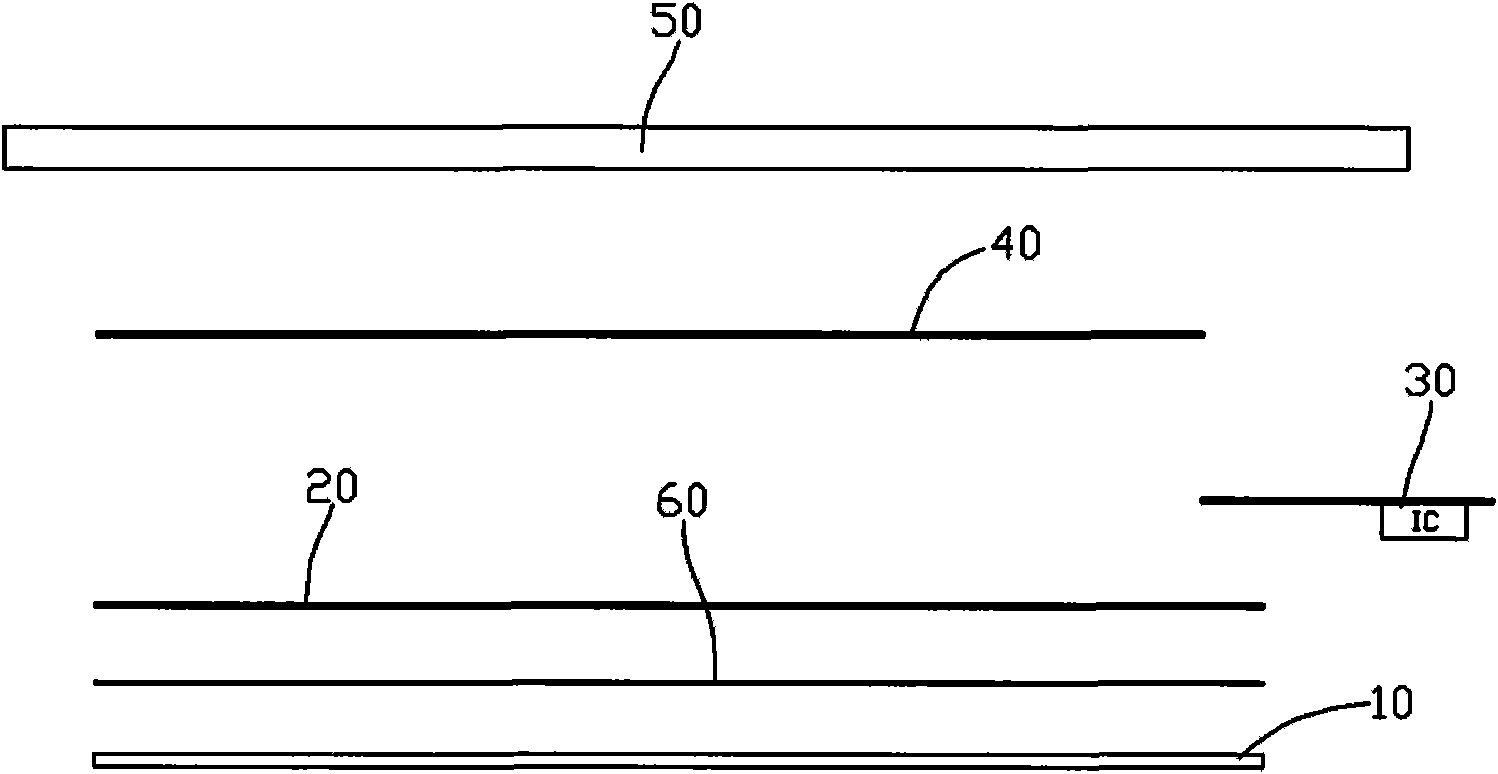

[0017] attached figure 1 Sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com