Production process of ethyl acetate

An ethyl acetate and production process technology, applied in the field of ethyl acetate production technology, can solve the problems of increasing the energy consumption of a reactive distillation column, reducing the yield and purity of ethyl acetate products, and avoiding waste and improving the purity. , The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

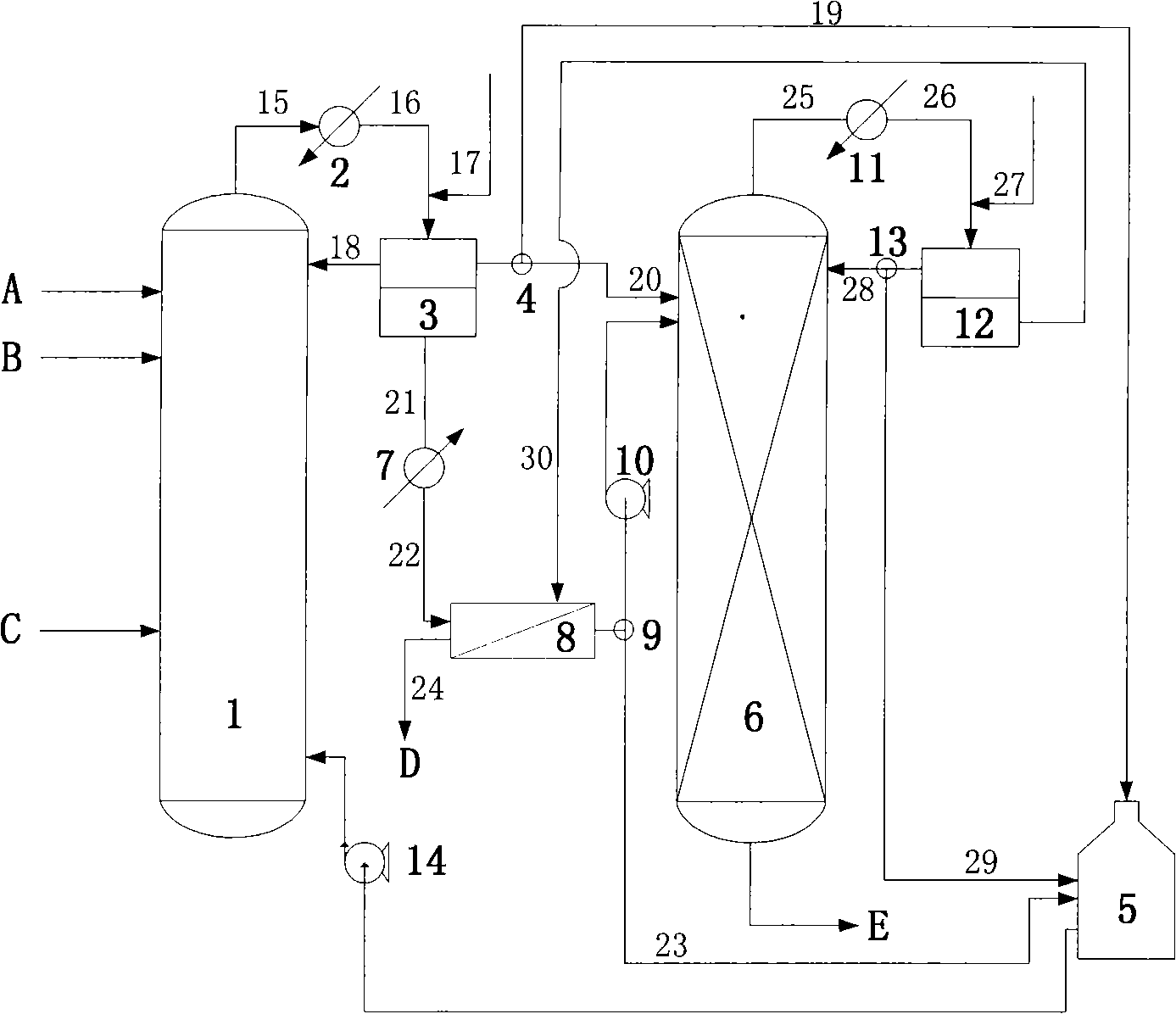

[0022] Embodiment 1. A kind of production technology of ethyl acetate

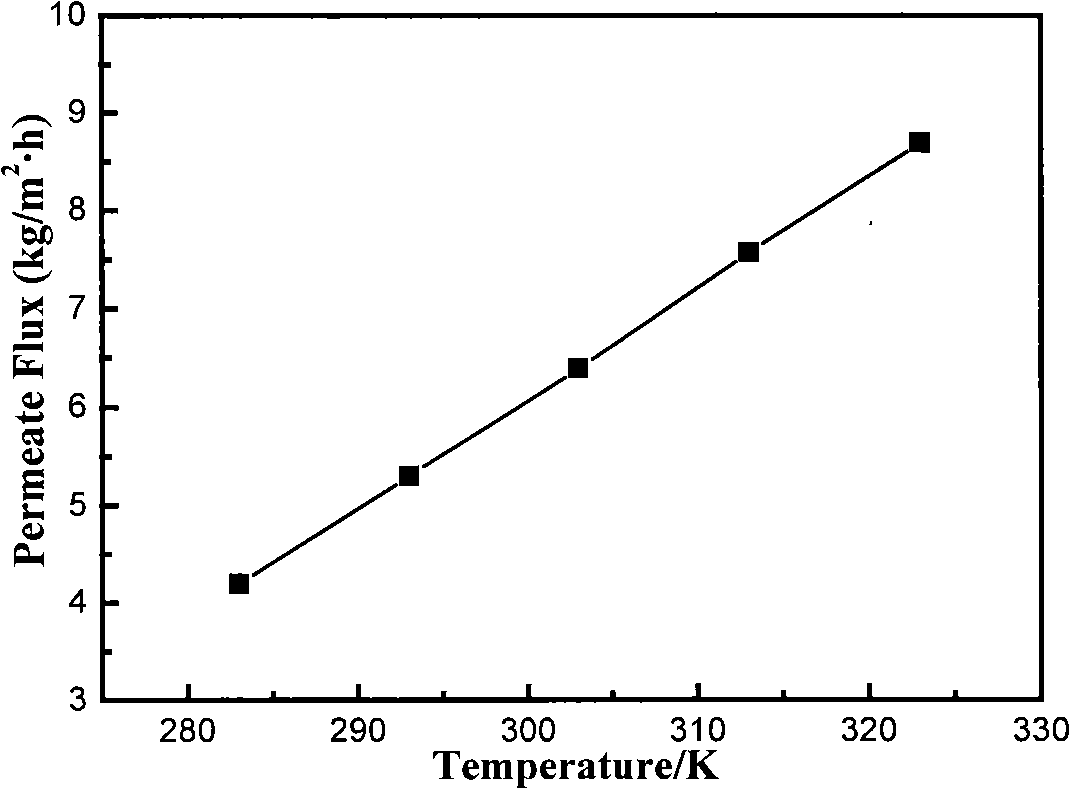

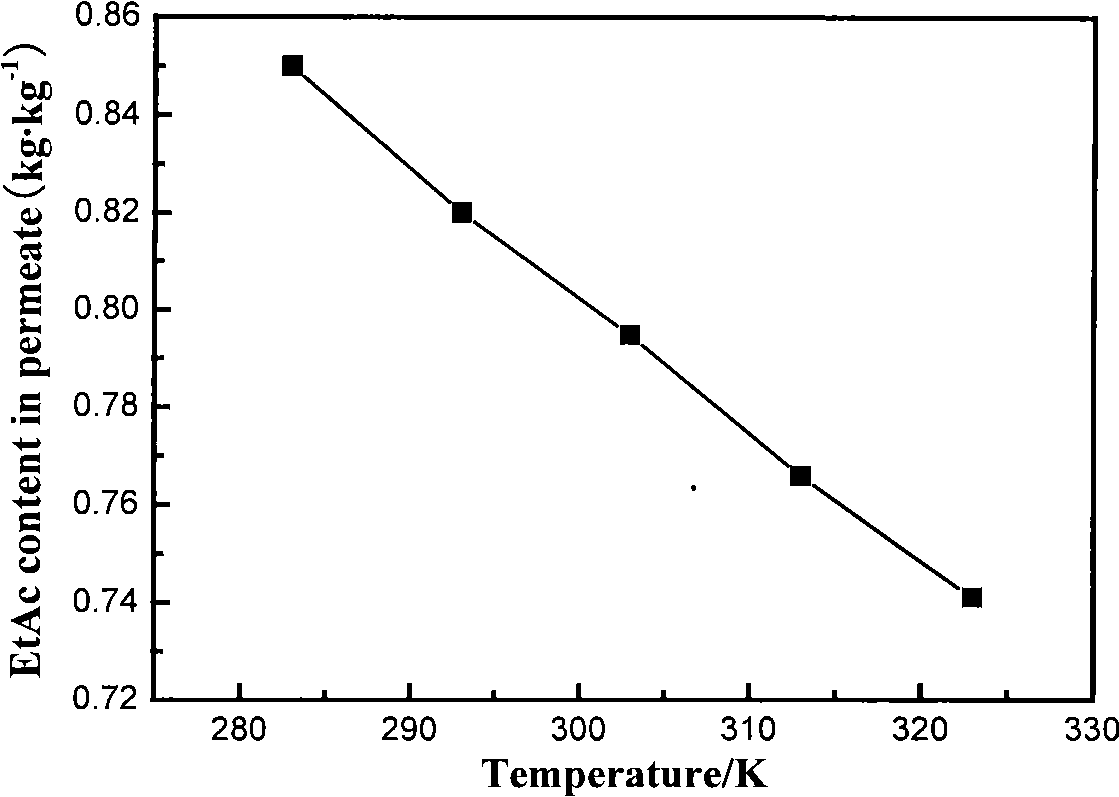

[0023] In this example, a tubular pervaporation membrane module is used, in which a self-made tubular composite membrane is used, the dense organic layer is polydimethylsiloxane, the thickness is 8 μm, and the effective membrane area is 12m 2, the porous support layer (Nanjing Jiusi Technology Co., Ltd., ceramic microfiltration membrane) has an average pore size of 0.5 μm and a thickness of 100 μm. The process conditions were calculated by using the chemical process simulation software Aspen Plus. Reactive distillation tower 1 is made of special stainless steel 316L, with 50 plates and a reflux ratio of 1.7. The feed rates of ethanol, acetic acid and concentrated sulfuric acid are 50kmol / h, 25kmol / h and 1.3mol / h respectively. Feed from the 35th, 5th and 9th trays respectively. The raw materials are sent to the reactive distillation column 1, the temperature at the top of the column is 75°C, the pressure ...

Embodiment 2

[0025] In this example, the dense film material of the top layer of the composite membrane that preferentially passes through organic matter is polydimethylsiloxane, and the thickness is 5 μm; 0.1μm, thickness 50μm, effective membrane area 5m 2 , all the other conditions are identical with embodiment 1, and the result is substantially consistent with embodiment 1.

Embodiment 3

[0027] In this example, the compact organic layer is polydimethylsiloxane with a thickness of 50 μm, and the porous support layer (Nanjing Jiusi High-Tech Co., Ltd., ceramic microfiltration membrane) has an average pore diameter of 10 μm and a thickness of 1000 μm. The effective membrane area is 25m 2 , all the other conditions are identical with embodiment 1, and the result is substantially consistent with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com