Sintered flat plate heat pipe and manufacturing method thereof

A technology for flat heat pipes and manufacturing methods, which is applied in indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as expansion pipe deformation, disturbing steam flow, etc., and achieve rolling or heat expansion, optimization of performance and thickness, and good The effect of the heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The sintered flat plate heat pipe of the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

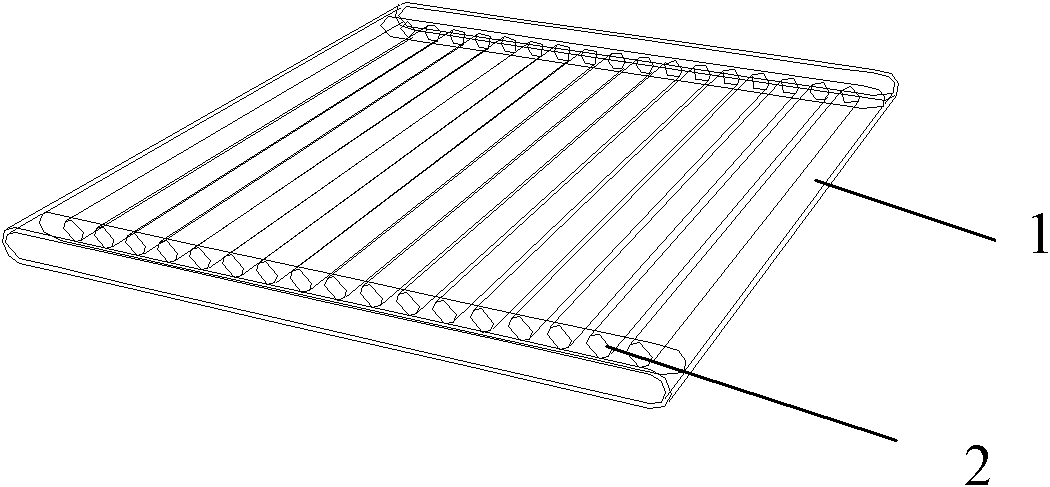

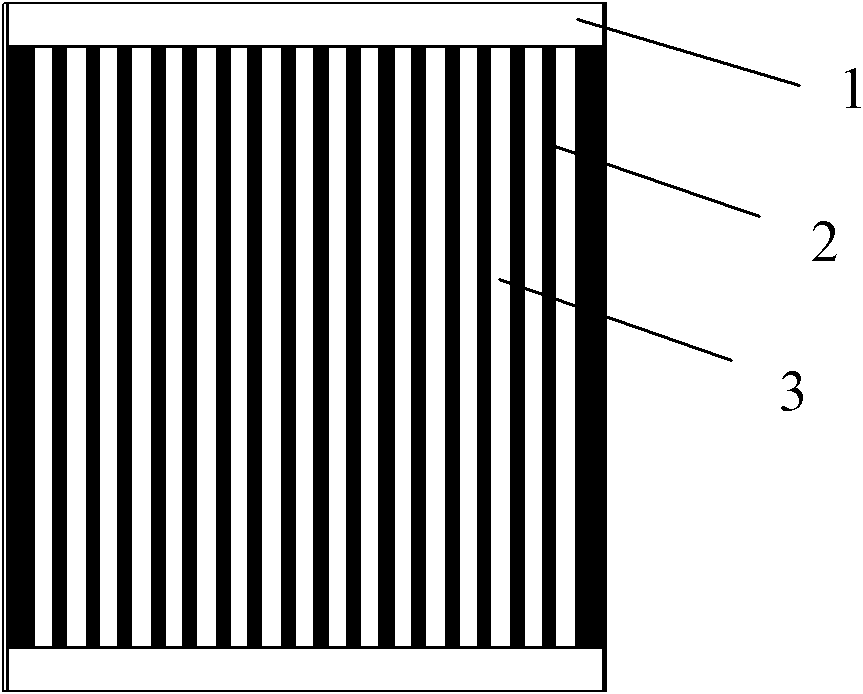

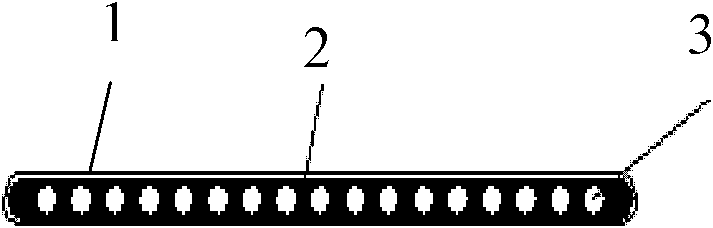

[0032] Such as figure 1 , 2 The sintered flat heat pipe shown in . The porous capillary structure 2 is formed by filling metal powder into the flat metal shell 1 with a central rod interspersed in advance, and sintering at high temperature. After sintering, the porous capillary structure 2 is closely and reliably connected with the upper and lower walls of the flat metal shell 1 . The steam channel 3 is formed when the central rod is drawn away from the porous capillary structure 2 after sintering, and runs through the porous capillary structure 2 in parallel. The porous capillary structure 2 between the steam channels 3 is also connected to the upper and lower walls of the airtight flat metal shell 1, which can not only make the condensed working fluid quickly return to the ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com