Apparatus and Method for Monitoring the Mechanical Properties of Subsea Longitudinal Vertical Components in Offshore Drilling and Production Applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

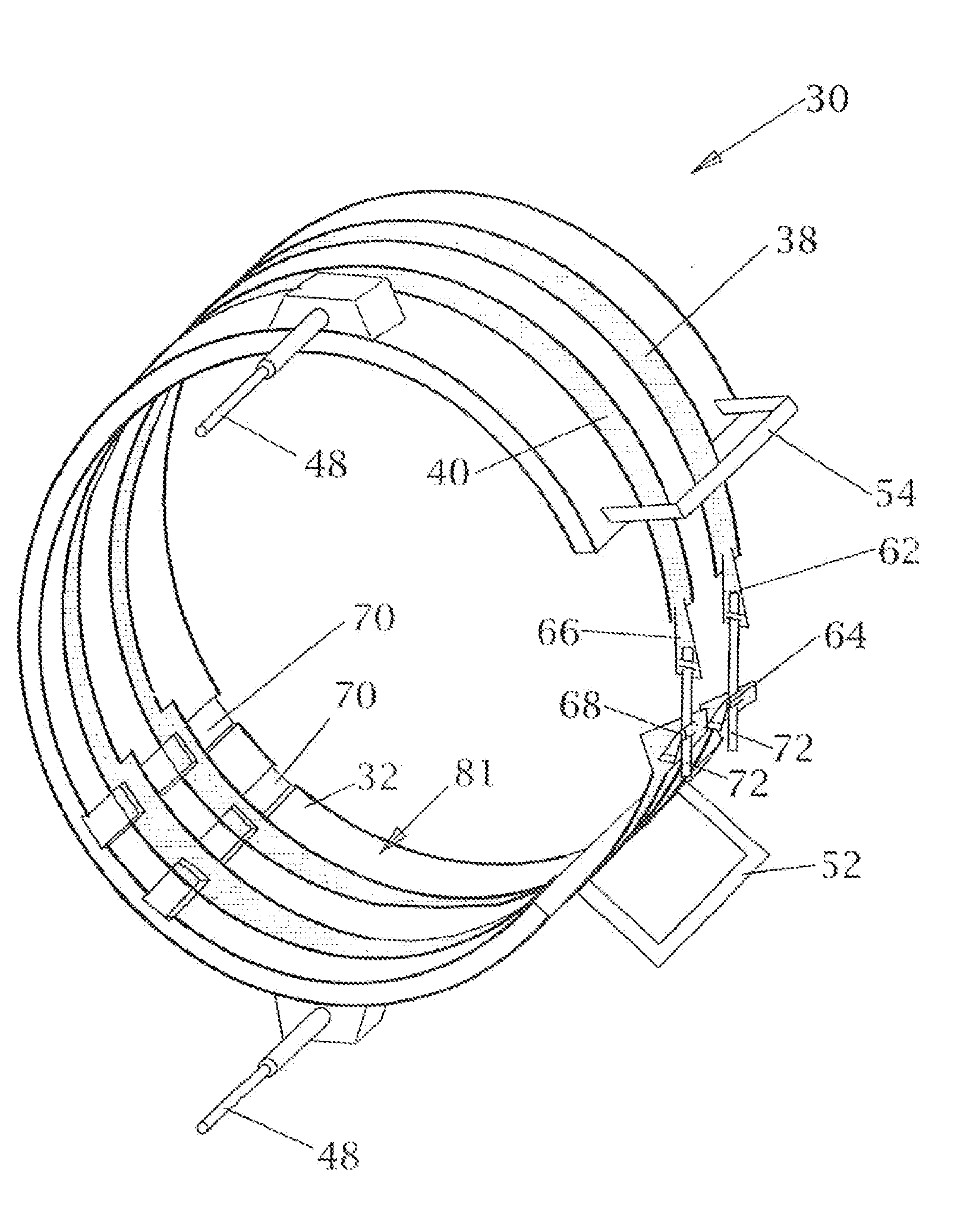

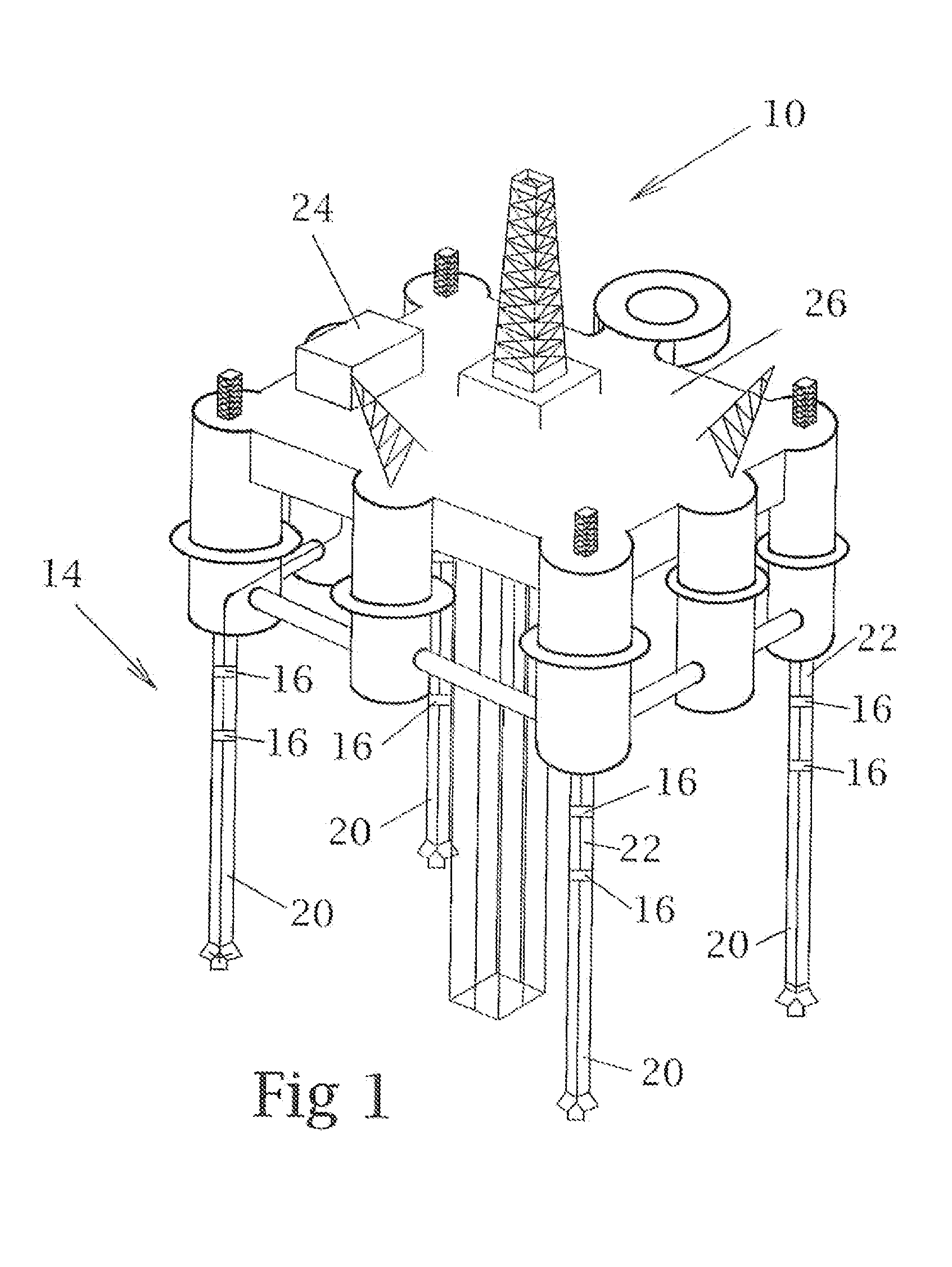

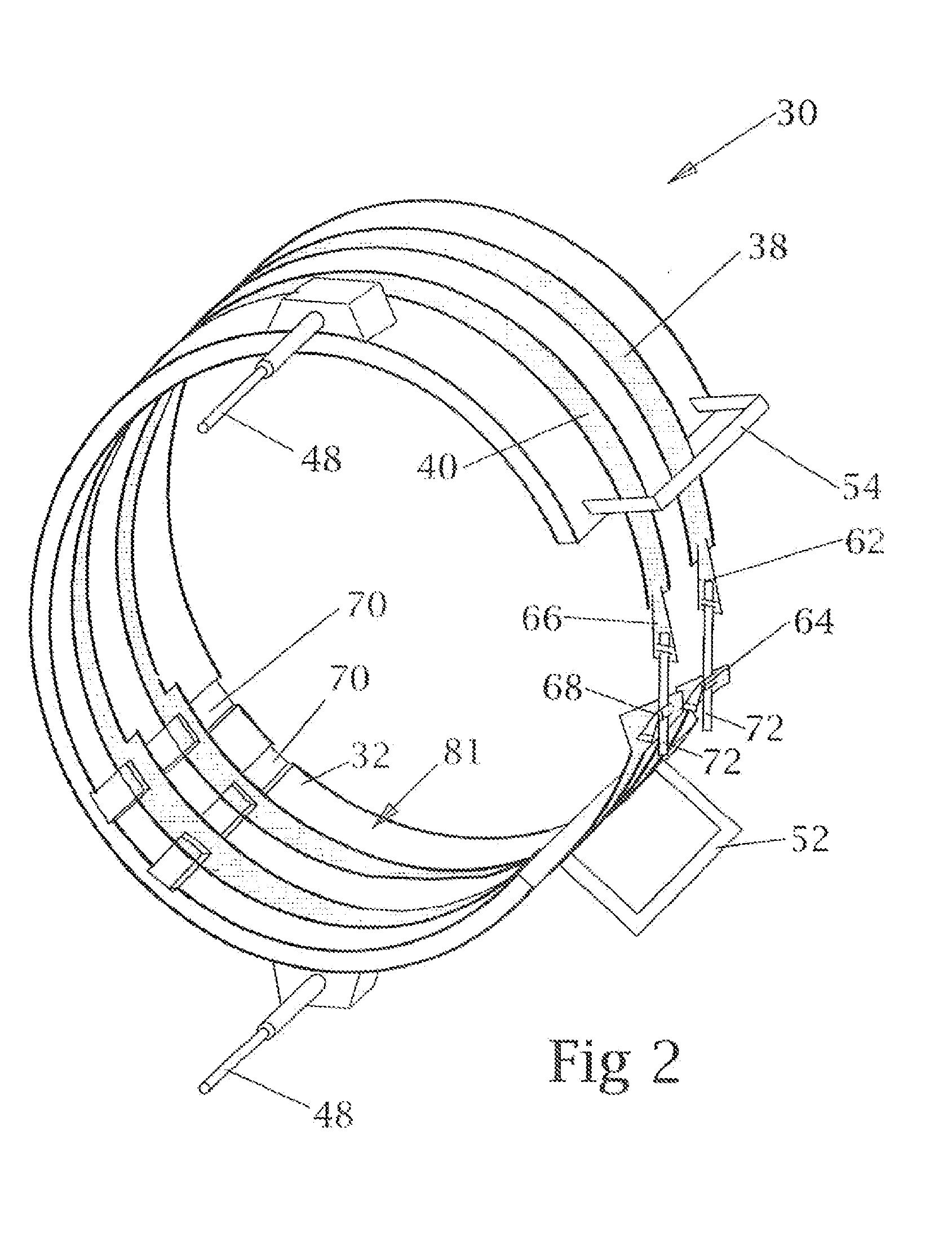

[0033]While the invention as described is illustrated using the sensor system 14 on the tension legs of a typical TLP 10, it should be understood that the system is readily adaptable to any SLVC incorporated in offshore drilling and production. The system is particularly useful, and similarly installed on risers, tension legs and other SLVC used during both the drilling and the production phase of the platform.

[0034]A TLP 10 with the sensor system 14 is shown in FIG. 1. In the preferred embodiment, the sensor system includes two groups of sensor assemblies 16 mounted on each tension leg 20. In the example, a first sensor ring 18 is mounted approximately thirty feet (eight to ten meters) from the mean sea surface and a second sensor ring 20 is mounted approximately sixty feet (sixteen to twenty meters from the surface. In some applications, it may be desirable to provide sensors strategically placed at intervals extending from the seafloor to a location near the surface platform. An ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com