Direct type ultrathin liquid crystal display device

A liquid crystal display device, a direct-type technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of large space occupation, difficulty in ultra-thin liquid crystal display device, increase of display device thickness, etc., to reduce thickness and realize ultra-thin Thin, well-conceived effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

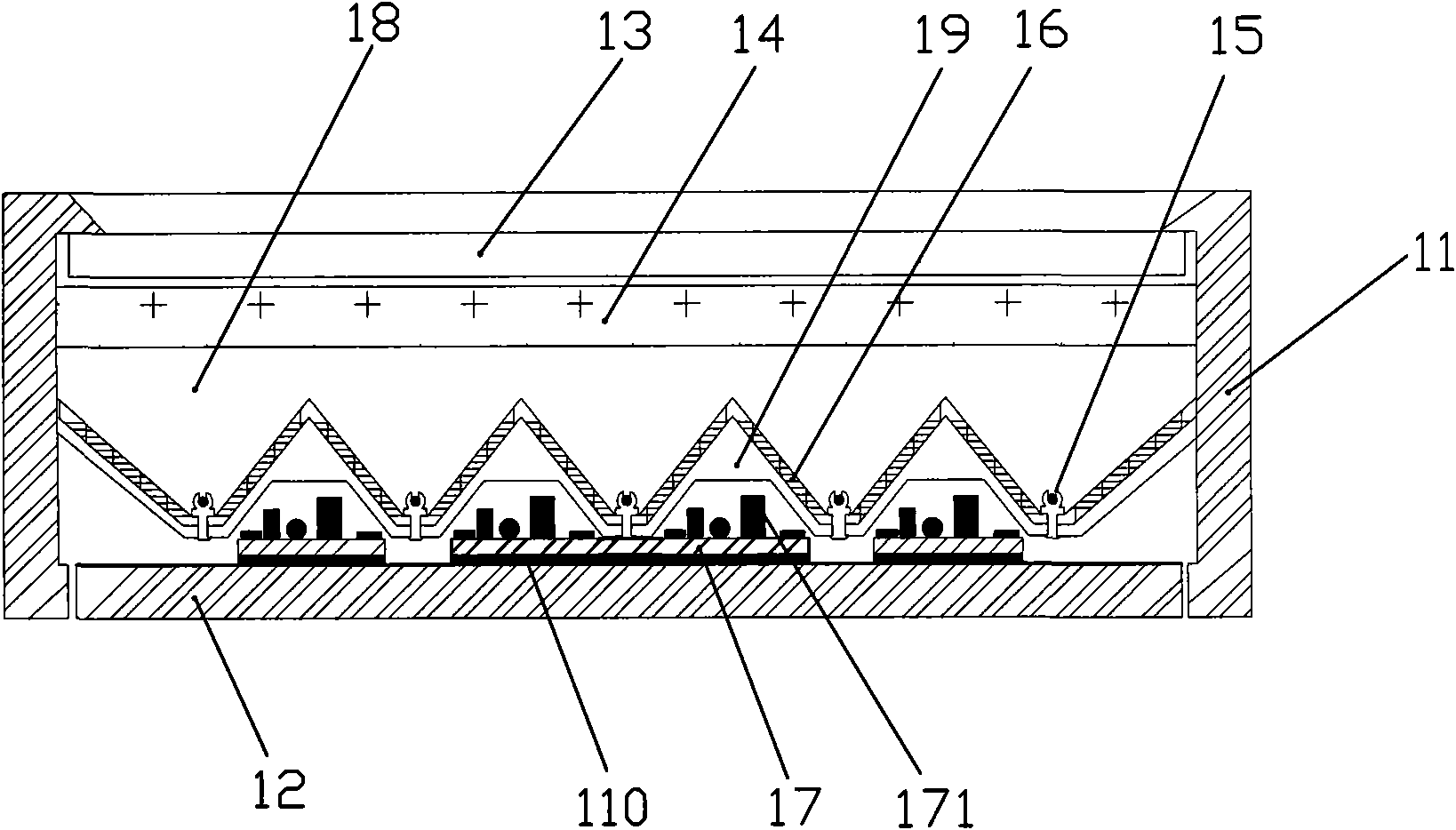

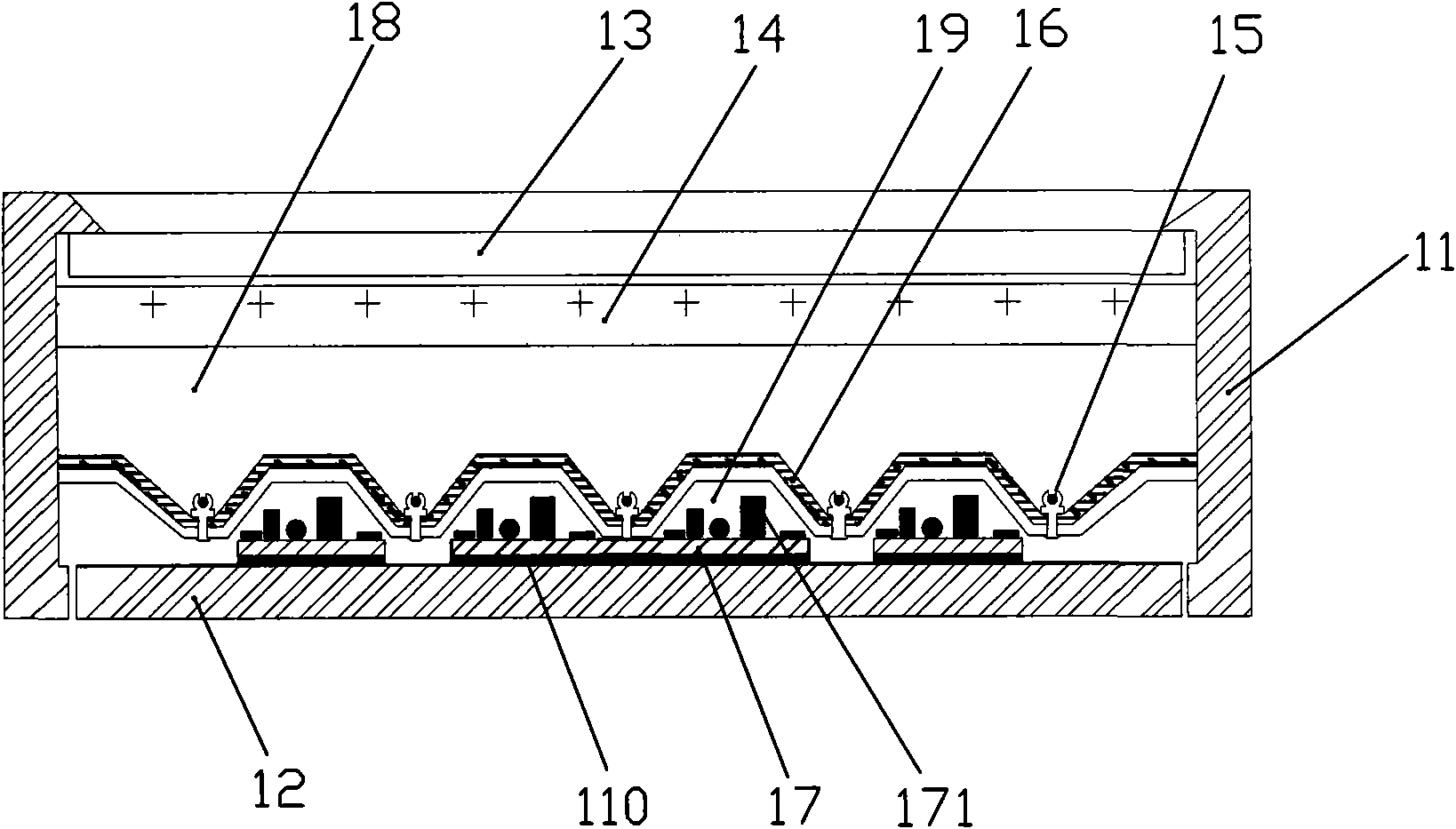

[0025] Such as Figure 2A , Figure 2B with image 3 As shown, a direct-type ultra-thin liquid crystal display device provided by Embodiment 1 of the present invention includes a front cover 11 and a rear cover 12. The front cover 11 and the rear cover 12 cooperate to form a cavity, and the cavity is provided with Display screen 13, diffusion film 14, light source 15, reflection film 16 and PCB board 17, described PCB board 17 is provided with some electronic components 171, and described reflection film 16 is the convex-concave structure of non-planar, and described light source 15 is located at The cavity 18 formed between the reflective film 16 and the diffusion film 14 is located in the recess of the reflective film 16, the PCB board 17 and the circuit components 171 on it are arranged on the reflective film 16 and the back cover 12 and is fixed on the back cover 12 in the cavity 19 formed between them. Compared with the existing direct-type liquid crystal display devic...

Embodiment 2

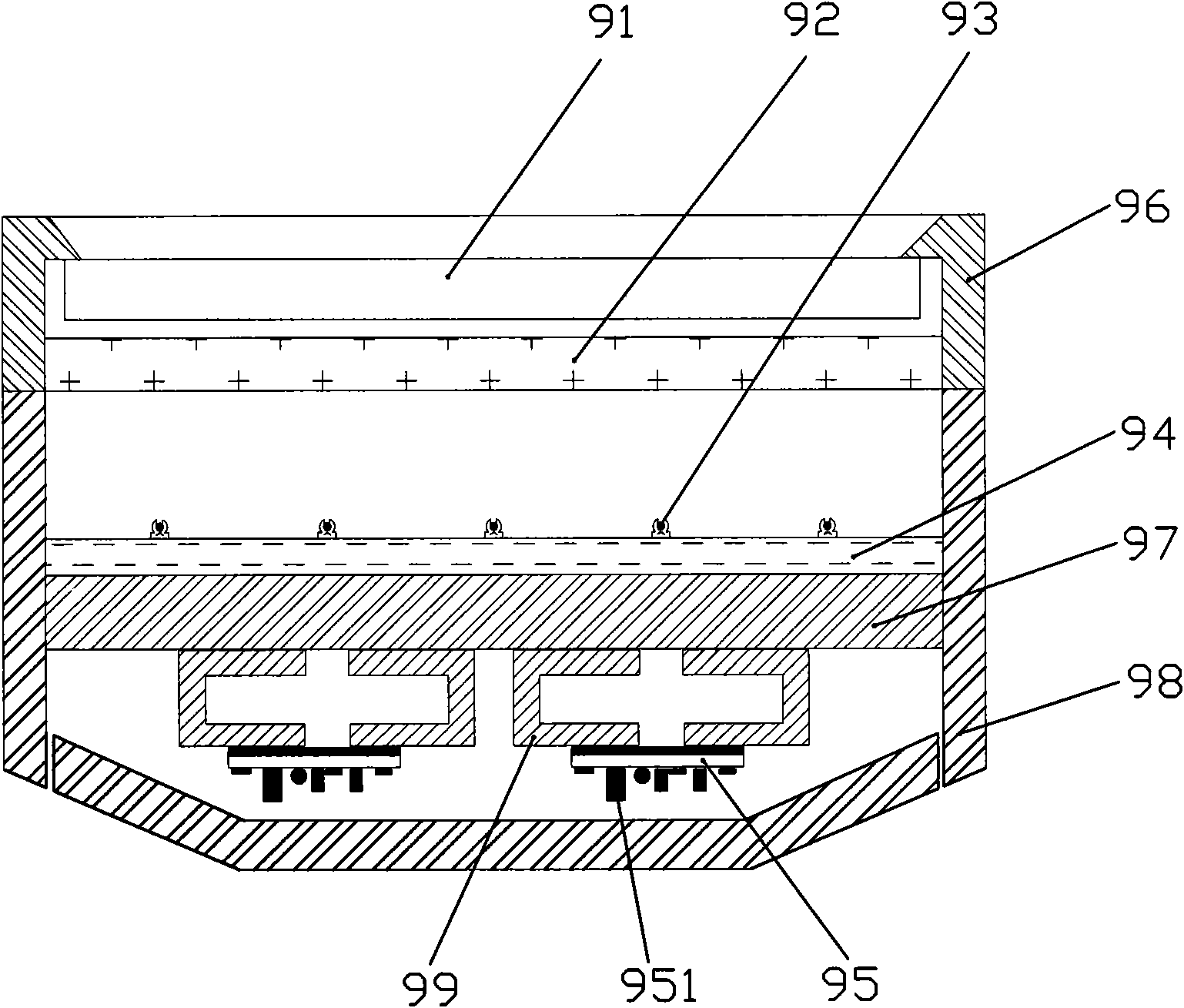

[0032] Such as Figure 4 As shown, a direct-type ultra-thin liquid crystal display device provided by Embodiment 2 of the present invention includes a front cover 21 and a rear cover 22. The front cover 21 and the rear cover 22 cooperate to form a cavity, and the cavity is provided with Display screen 23, diffusion film 24, light source 25, reflection film 26 and PCB board 27, described PCB board 27 is provided with some electronic components 271, and described reflection film 26 is planar structure, and described light source 25 is located at described reflection The cavity 28 formed between the film 26 and the diffusion film 24 is located on the reflective film 26, and the PCB board 27 and the circuit components 271 on it are scattered between the light sources 25 and located on the reflective film. on the membrane 26. Compared with the existing direct-type liquid crystal display device, in the second embodiment of the present invention, the PCB board 27 and the circuit ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com