Surface deformation distribution test sensing element

A technology for distributed testing and sensing elements, which is applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement devices, etc. Problems such as the stiffness of the medium to be measured does not match

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

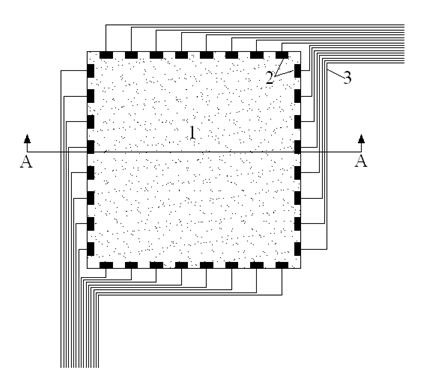

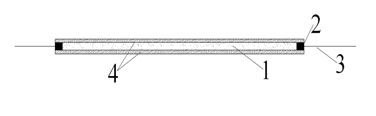

[0015] Embodiment 1, as figure 1 image 3 As shown, the surface deformation distribution test sensing element includes a flexible sensing film 1, electrodes 2 evenly spaced around the flexible sensing film 1, wires 3 connected to the electrodes, and flexible insulating layers attached to the upper and lower surfaces of the flexible sensing film 4. The flexible sensing film 1 is made of a carbon black-filled rubber-based conductive composite material with a thickness of 40 μm. The shape of the flexible sensing film 1 is a square with a side length of 250 mm. The 32 electrodes are arranged at equal intervals of 8 on each side. The electrode 2 is made of a 0.05mm thick copper sheet with a size of 5mm×10mm, and the electrodes 2 are connected with wires 3 . The copper electrode 2 and the flexible sensing film 1 are bonded with conductive adhesive, and the wire 3 is welded to the electrode 2 . A layer of flexible insulating layer 4 poured with liquid silicone rubber is respective...

Embodiment 2

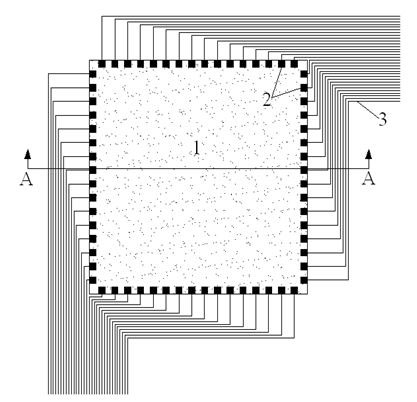

[0016] Embodiment 2, as figure 2 image 3 As shown, the surface deformation distribution test sensing element includes a flexible sensing film 1, electrodes 2 evenly spaced around the flexible sensing film 1, wires 3 connected to the electrodes, and flexible insulating layers attached to the upper and lower surfaces of the flexible sensing film 4. The flexible sensing film is made of a rubber-based conductive composite material filled with carbon nanotubes and carbon black. Each electrode is made of 0.05mm thick copper sheet with a size of 5mm×5mm, and each electrode is connected with a wire. The copper electrode 2 and the flexible sensing film 1 are bonded with conductive adhesive, and the wire 3 is welded to the electrode 2 . A layer of flexible insulating layer 4 poured with liquid silicone rubber is respectively attached to the upper and lower surfaces of the flexible sensing film 1 and the joints of the electrodes 2. The liquid silicone rubber is used to cast the flex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com