Inserting electrode lead-out method for micro platinum thermal resistance temperature sensor

A temperature sensor, platinum thermal resistance technology, applied in the direction of resistors, non-adjustable metal resistors, resistors with lead-out terminals, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

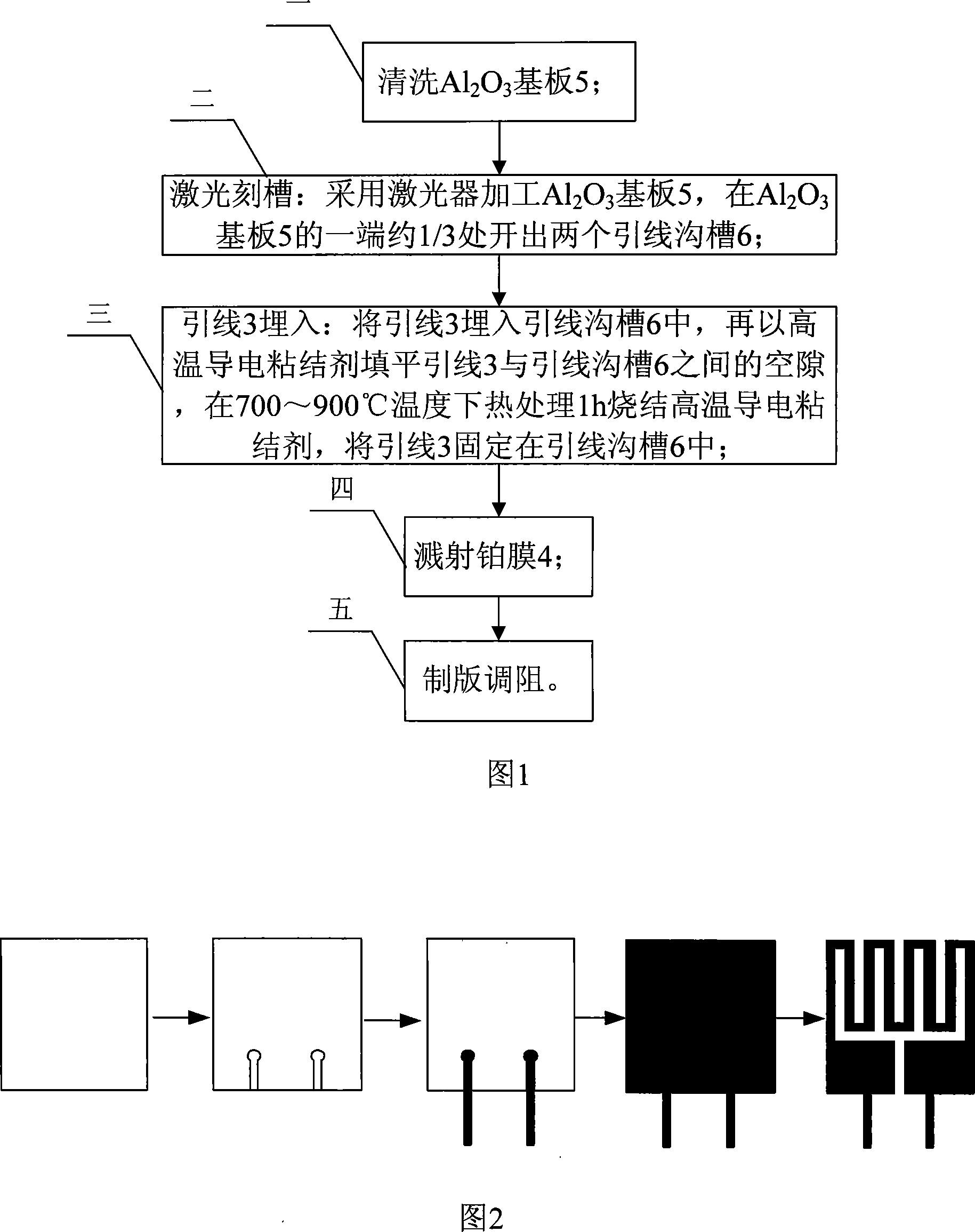

[0013] Specific embodiment one: illustrate this embodiment in conjunction with Fig. 1 and Fig. 2, the steps of this embodiment are as follows:

[0014] Step 1: Clean Al 2 o 3 Substrate 1;

[0015] Step 2: Laser grooving: use laser to process Al 2 o 3 Substrate 1, in Al 2 o 3 Two electrode grooves 2 are opened at about 1 / 3 of one end of the substrate 1;

[0016] Step 3: Embedding of electrode 3: Embedding electrode 3 in electrode groove 2, filling the gap between electrode 3 and electrode groove 2 with high-temperature conductive adhesive, heat treatment at 700-900°C for 1 hour and sintering A high-temperature conductive adhesive to fix the electrode 3 in the electrode groove 2;

[0017] Step 4: sputtering platinum film 4;

[0018] Step 5: Plate making and resistance adjustment.

specific Embodiment approach 2

[0019] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the high-temperature conductive adhesive is a mixture of glass frit and platinum paste in a ratio of 1:5 to 1:10; other compositions and connection methods are the same as in Embodiment 2 One is the same.

specific Embodiment approach 3

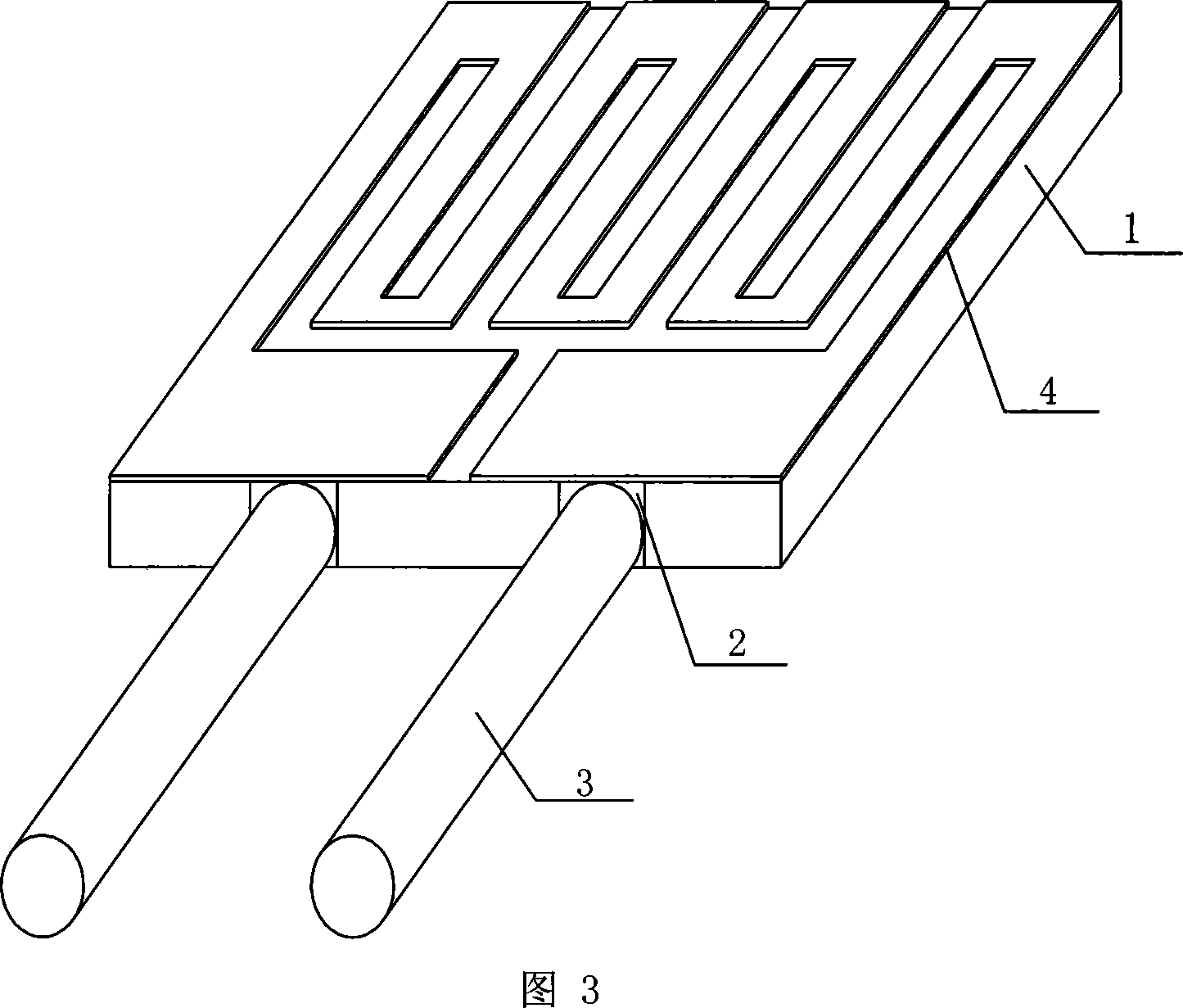

[0020] Specific embodiment three: This embodiment is described in conjunction with FIG. 3. The difference between this embodiment and specific embodiment one is that the overall thickness of the embedded electrode miniature platinum thermal resistance temperature sensor is 0.15-0.65 mm, which reduces the overall thickness of the sensor. Reaching the ultra-thin requirement; other composition and connection methods are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com