Inserting electrode lead-out method for micro platinum thermal resistance temperature sensor

A technology of temperature sensor and platinum thermal resistance, applied in the direction of resistors, non-adjustable metal resistors, resistors with lead-out terminals, etc., can solve the problems that cannot meet the requirements of ultra-thin body, and achieve strong operability and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

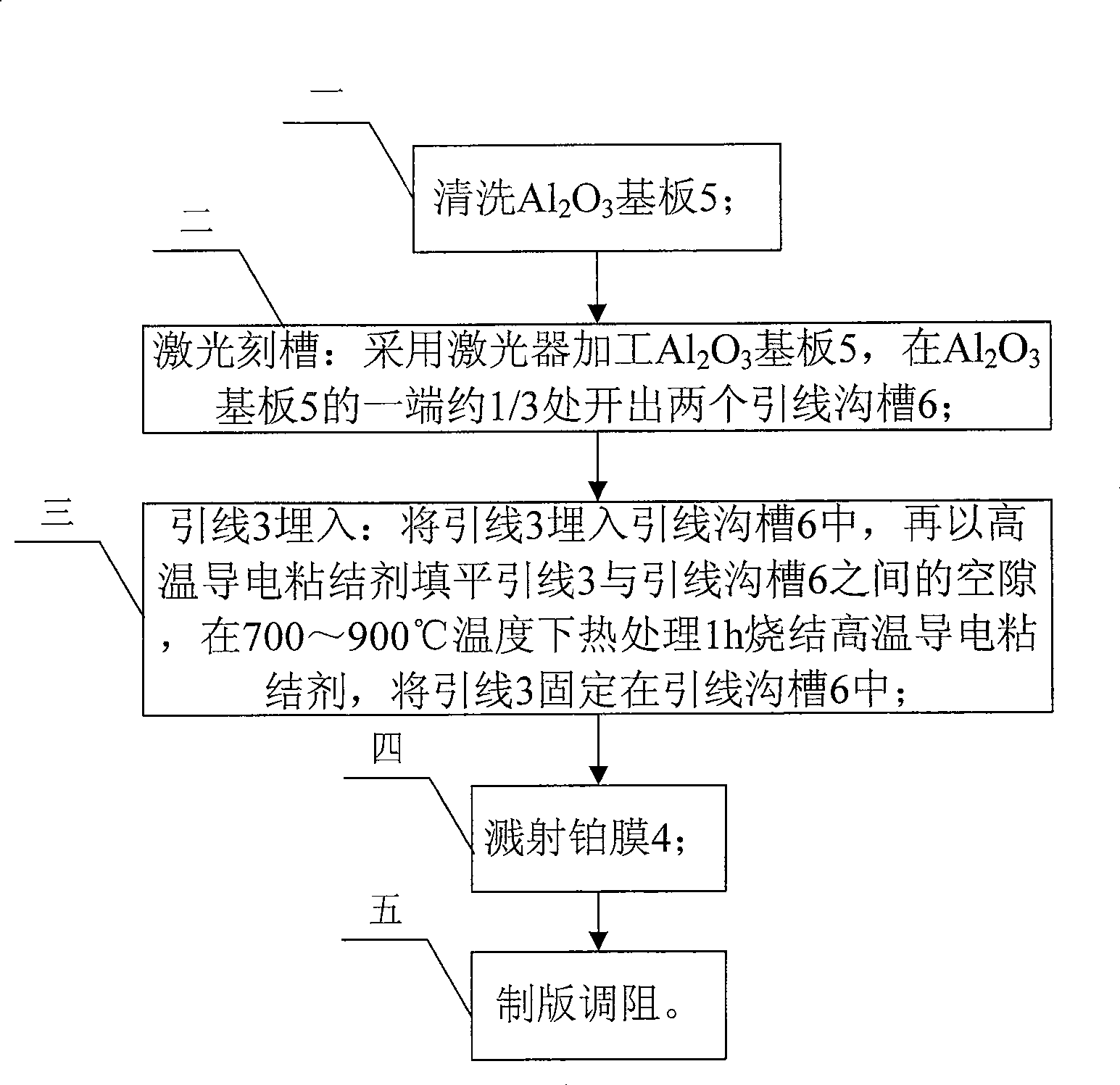

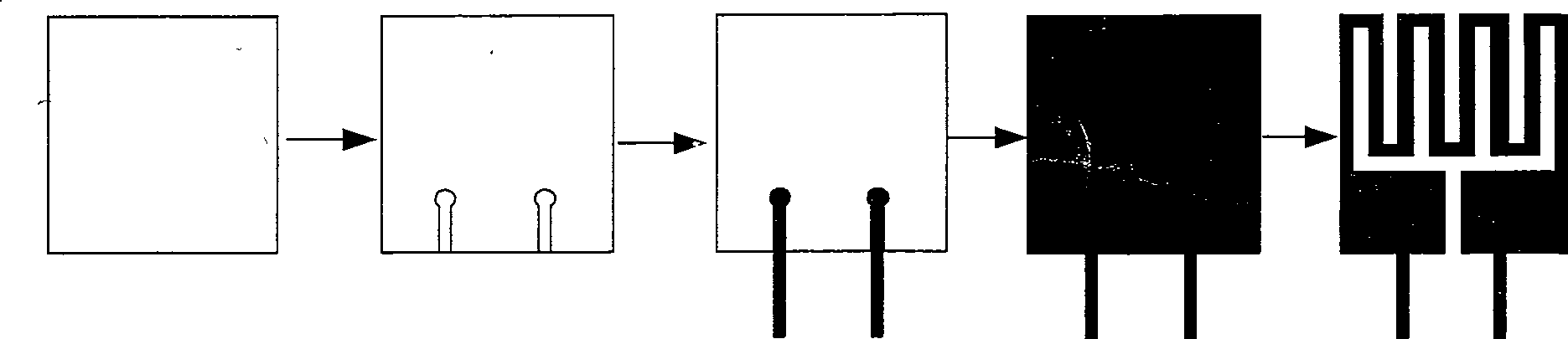

[0013] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, the steps of this embodiment are as follows:

[0014] Step 1: Clean Al 2 o 3 Substrate 1;

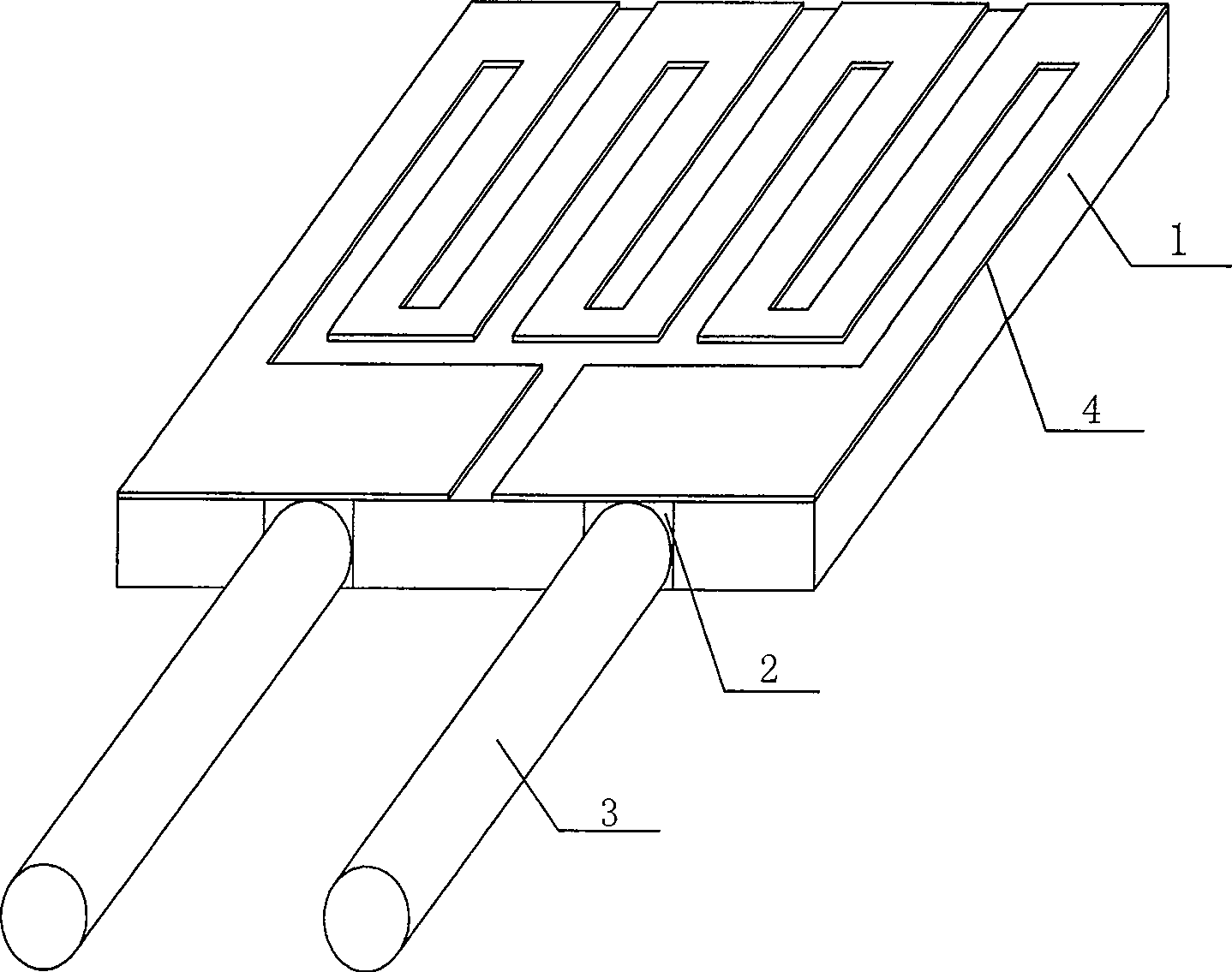

[0015] Step 2: Laser grooving: use laser to process Al 2 o 3 Substrate 1, in Al 2 o 3 Two electrode grooves 2 are opened at about 1 / 3 of one end of the substrate 1;

[0016] Step 3: Embedding of electrode 3: Embedding electrode 3 in electrode groove 2, filling the gap between electrode 3 and electrode groove 2 with high-temperature conductive adhesive, heat treatment at 700-900°C for 1 hour and sintering A high-temperature conductive adhesive to fix the electrode 3 in the electrode groove 2;

[0017] Step 4: sputtering platinum film 4;

[0018] Step 5: Plate making and resistance adjustment.

specific Embodiment approach 2

[0019] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the high-temperature conductive adhesive is a mixture of glass frit and platinum paste in a ratio of 1:5 to 1:10; other compositions and connection methods are the same as the specific embodiment One is the same.

specific Embodiment approach 3

[0020] Specific implementation mode three: combination image 3 Describe this embodiment, the difference between this embodiment and the specific embodiment is that the overall thickness of the embedded electrode miniature platinum thermal resistance temperature sensor is 0.15-0.65 mm, which reduces the overall thickness of the sensor and meets the ultra-thin requirement; other components The connection method is the same as that in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com