Microreactors, systems and liquid acid alkylation methods for liquid-liquid multiple phase applications

A technology of microreactors and multiphase reactions, applied in chemical instruments and methods, chemical/physical/physicochemical reactors, chemical/physical processes, etc., can solve limited applications and affect the reaction effect of tubular membrane microreactors, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

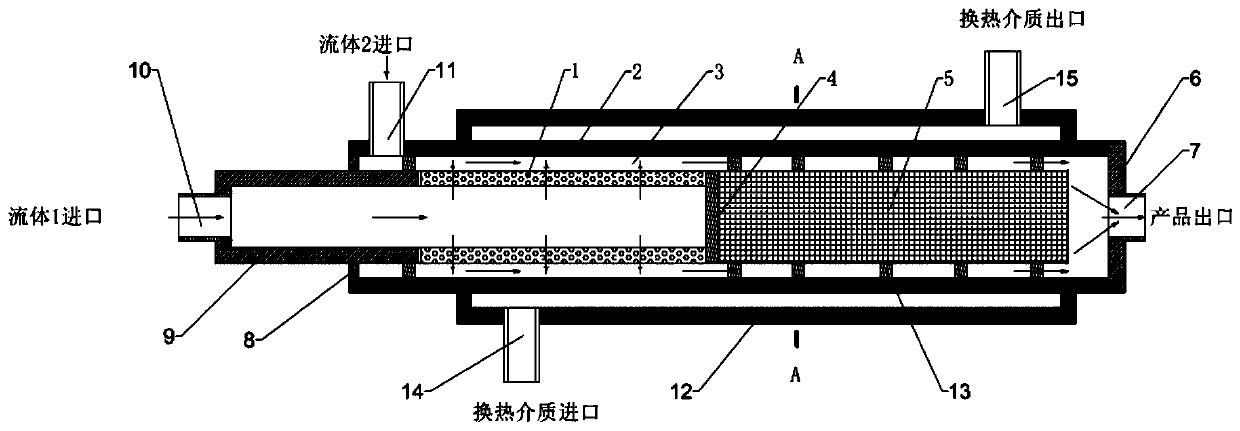

[0080] A liquid-liquid multiple phase application microreactor, such as figure 1As shown, it consists of a coaxially fixed inner tube, sleeve 2 and heat exchange tube 12, wherein the inner tube includes a flow guide tube 9, a film tube 1 and a flow guide tube 5 connected in sequence from left to right, and the flow guide tube 9 communicates with the membrane tube 1, the plug 4 between the diversion tube 5 and the membrane tube 1 is isolated, and an annular microchannel 3 with a radial width of 0.5mm is formed between the inner tube and the sleeve tube 2, and an inlet is provided at one end of the inner tube. The feed pipe 10 and the upper side of the sleeve pipe 2 are provided with a feed pipe 11, which is a tangential feed pipe. One end of the casing 2 and the wall of the inner pipe are closed with a plug 8, the other end is provided with a discharge pipe 7, and the rest is closed with a plug 6, and the annular microchannel 3 is spirally distributed with positioning strips 13...

Embodiment 2

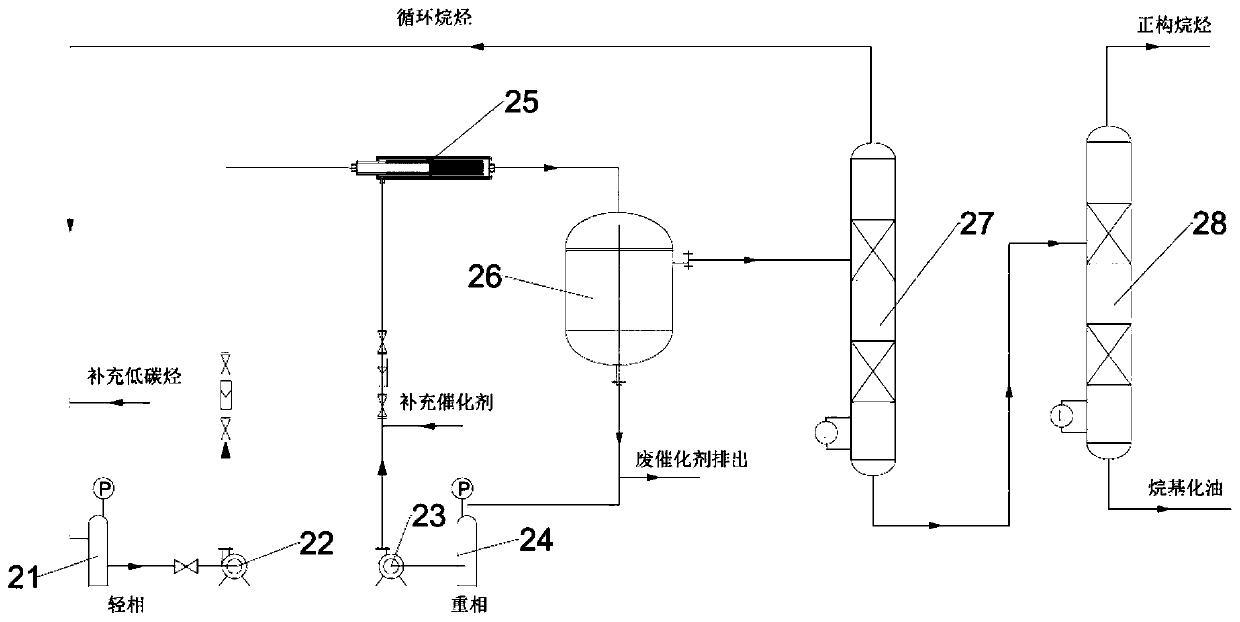

[0083] A liquid-liquid multiphase reaction system, such as figure 2 As shown, it consists of the following devices:

[0084] 1) sleeve type membrane emulsion microreactor 25, structure such as figure 1 shown;

[0085] 2) a light phase storage tank 21, which is connected to the feed pipe 10 through a light phase delivery pipeline, and a light phase delivery pump 22 is arranged on the pipeline;

[0086] 3) a heavy phase storage tank 24, which is connected to the feed pipe 11 through a heavy phase delivery pipeline, and a heavy phase delivery pump 23 is arranged on the pipeline;

[0087] 4) acid hydrocarbon separator 26, the heavy phase outlet at the bottom of which is connected to the heavy phase storage tank 24;

[0088] 5) De-isobutanizer 27 and de-n-butanizer 28, de-isobutanizer 27 is connected with the light phase outlet of acid hydrocarbon separator 26 top, and the top of de-isobutanizer 27 is connected with light phase storage tank 21 The bottom of de-isobutanizer 27 ...

Embodiment 3

[0090] A kind of liquid acid alkylation method using isobutane and olefin as raw material, utilizes the system of embodiment 2 to carry out, and the steps are as follows:

[0091] The mixture of olefins and isobutane is stored in the light phase storage tank 21, and enters the reactor 25 after metering through the light phase delivery pump 22; the liquid acid catalyst is stored in the heavy phase storage tank 23, and enters after being metered through the heavy phase delivery pump 24 Reactor 25; hydrocarbons pass through the membrane tube 1 as the dispersed phase, enter the microchannel 3 in the form of microemulsion droplets, and then mix and react with the continuous phase of the liquid acid catalyst in the microchannel, and the reaction is carried out at 8 ° C. The reaction pressure is 0.4MPa, the volume ratio of raw material isobutane and olefin is 8:1, the volume ratio of catalyst and raw material is 1:1, and the reaction time is 5min; the reaction product enters the acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com