High-brightness ultrathin light semiconductor device

An optical semiconductor, high-brightness technology, applied in the direction of semiconductor devices, electrical solid devices, electrical components, etc., can solve problems such as shedding, thermal deformation of printed circuit boards, expensive manufacturing costs, etc., and achieve the effect of improving brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

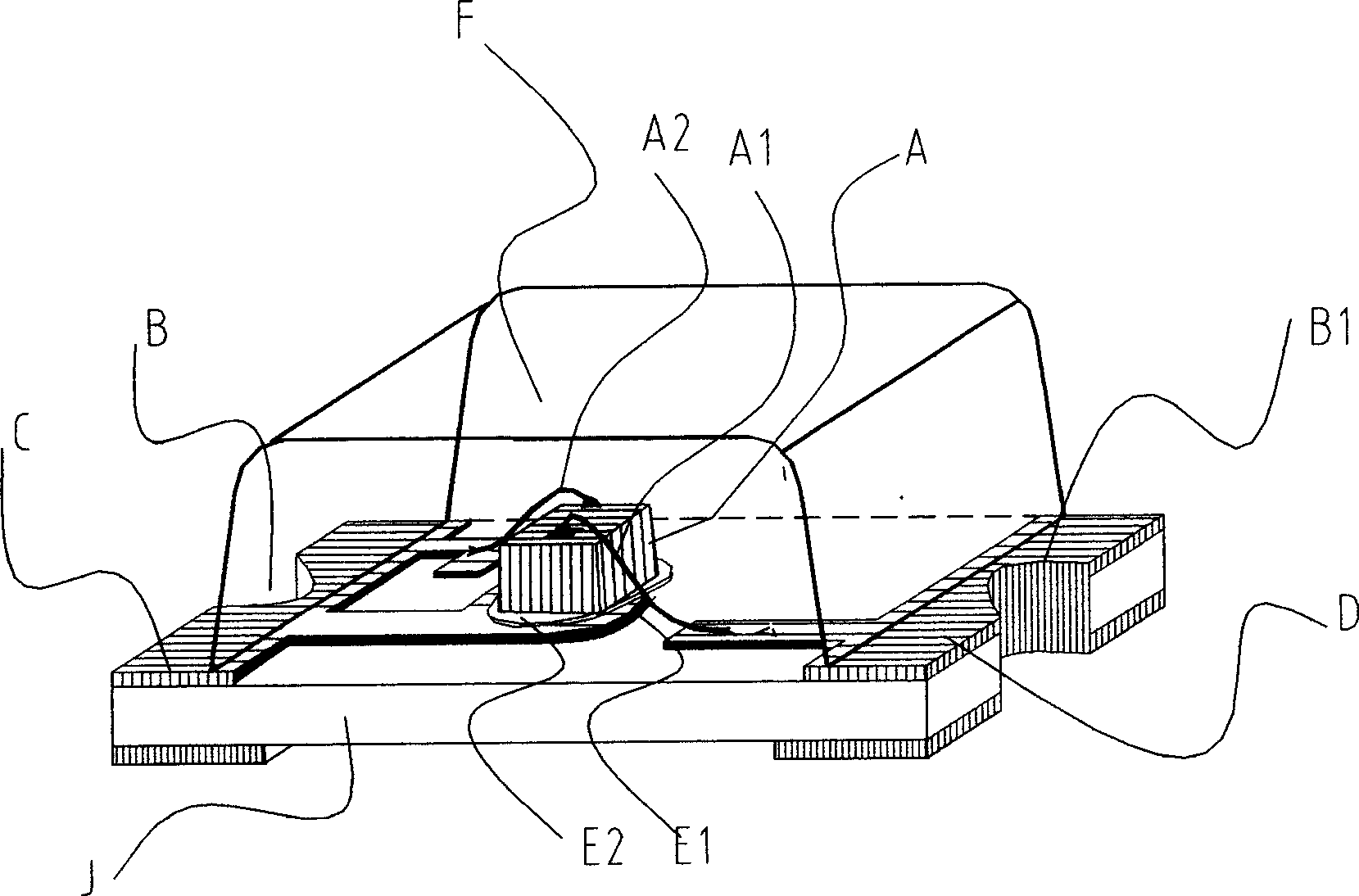

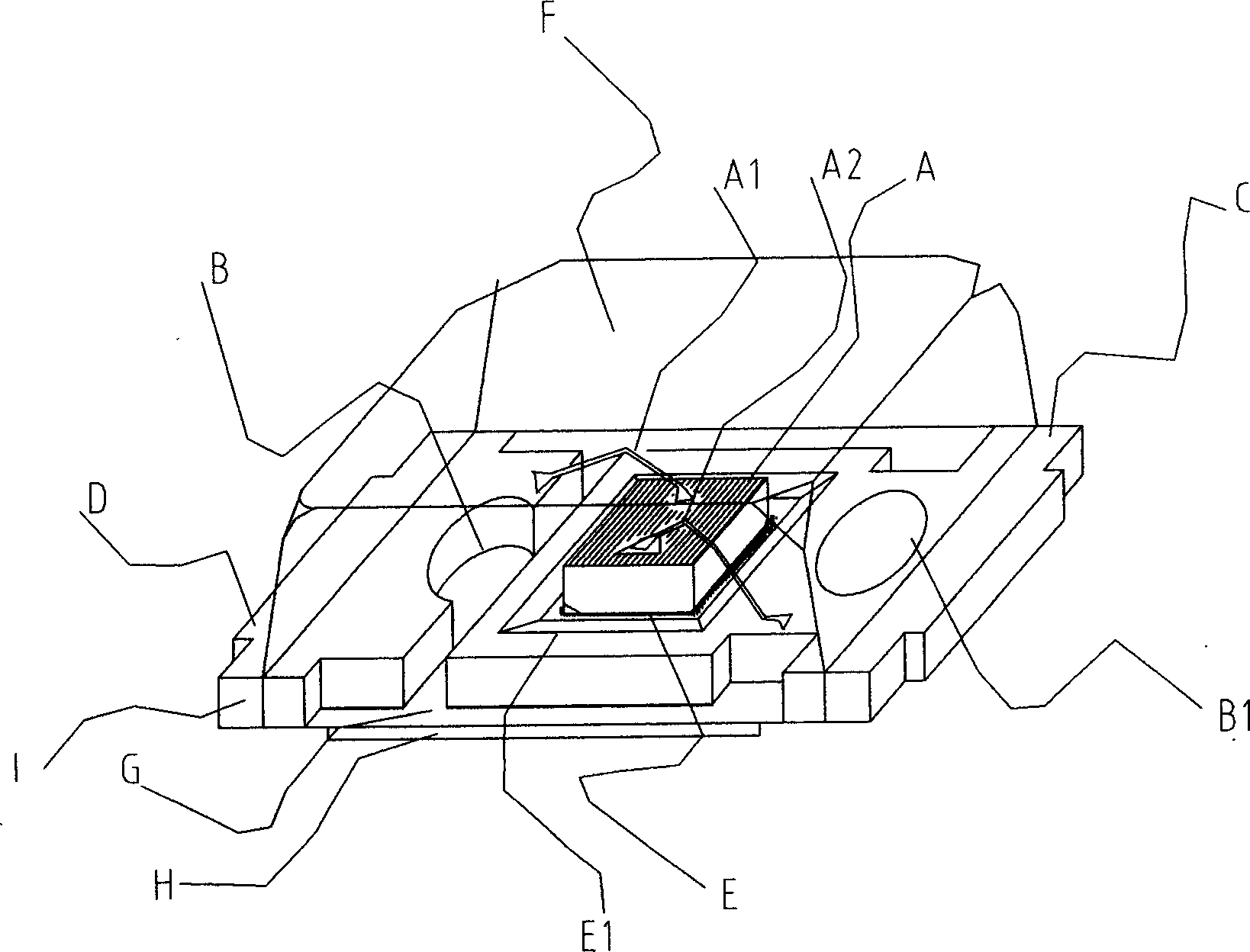

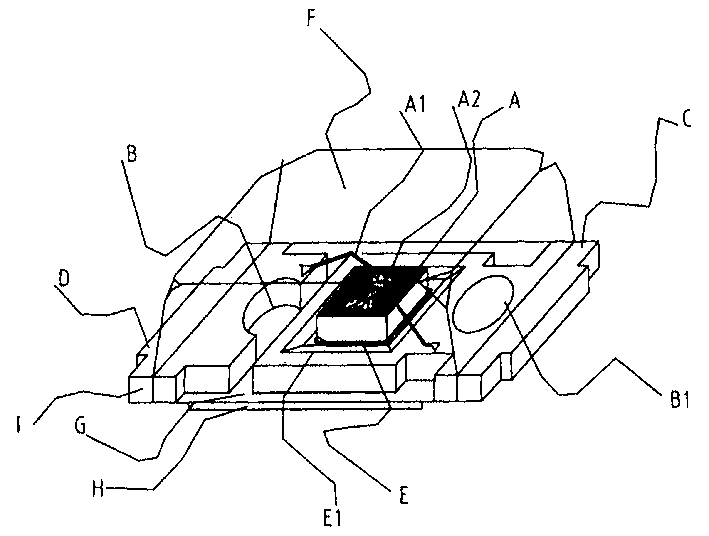

[0028] Such as figure 2 Shown, what the chip LED photo-semiconductor device of ultra-miniature of the present invention, ultrathin type is by anode lead frame (Anode Lead Frame) (D), negative electrode lead frame ((Dathode LeadFramed) (C), positive, negative electrode lead frame (D) Gold wires (A1) (A2) for conducting electricity between (C) and light-emitting chips (A), light-transmitting epoxy resin (F) for encapsulating the above two lead frames (D) (C), Lead The 10-50um protruding lower epoxy resin (H) formed on the lower end and the positive electrode lead through hole (B1) connecting Lead Frame, CathodeLead and the lower epoxy resin (H) to the upper epoxy resin (G), and the negative electrode lead through hole Hole (B2) constitutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com