High power LED two-dimension light source

A high-power, LED chip technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of increasing the cost of lamps, large differences in heat conduction paths, and affecting work, so as to improve the level of automated production and improve visual comfort. , The effect of simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] High-power light-emitting diode (LED) two-dimensional light source, using LED chips directly packaged on metal aluminum-based circuit boards, integrating power chips into one body, forming a low-cost, highly integrated surface light source, with excellent heat dissipation function and uniform luminous effect .

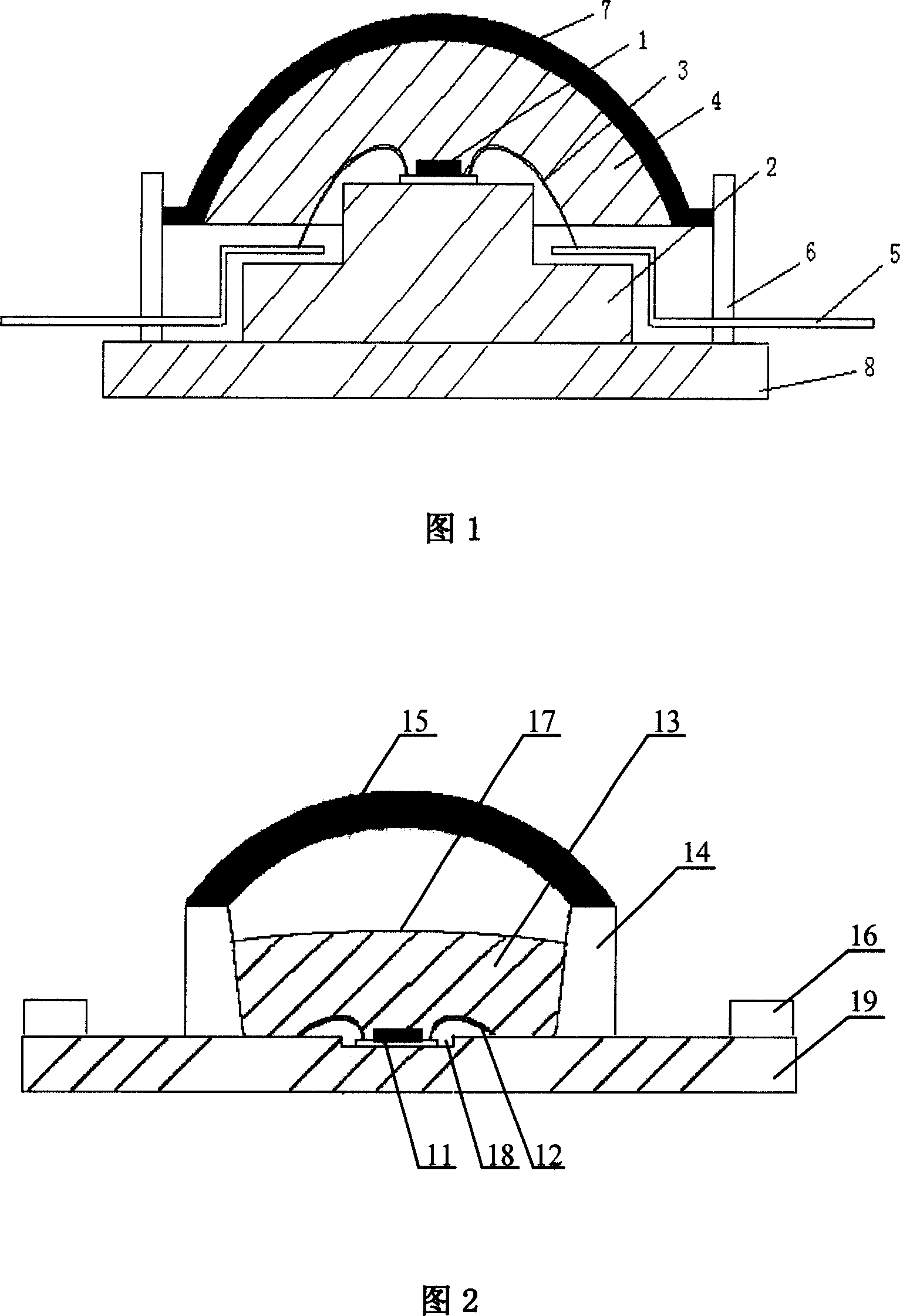

[0024] The structure of the single two-dimensional light source of the present invention is shown in Figure 2, including: a high-power light-emitting diode chip 11, a metal wire 12, a metal aluminum-based circuit board 19 and a bowl-shaped pit 18, a plastic light reflection bowl 14, and a transparent package. Resin 13 and curved surface 17, lens 15 and electrical connection socket 16 molded by process mold.

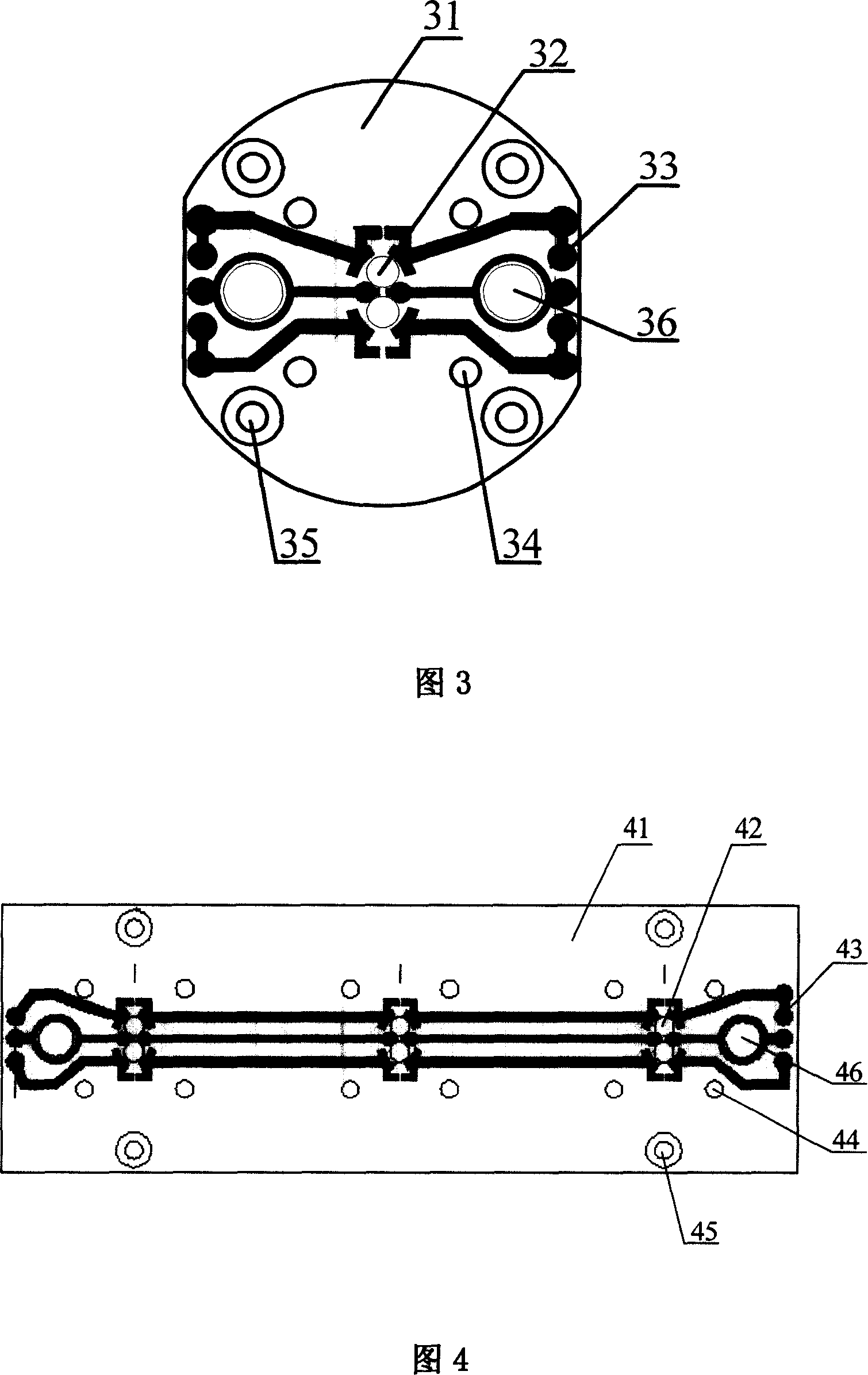

[0025] The metal aluminum-based circuit board of a single two-dimensional light source product is shown in Figure 3. In the figure: aluminum alloy plate 31, bowl-shaped pit 32, plastic light reflection bowl positioning hole 34, standard-spaced pads 33, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com