Stacking machine and stacking method

A stacker and rack technology, applied in the field of logistics equipment, can solve the problems of poor stacking accuracy, high cost, and high labor intensity, and achieve the effects of improved stacking efficiency, improved accuracy, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

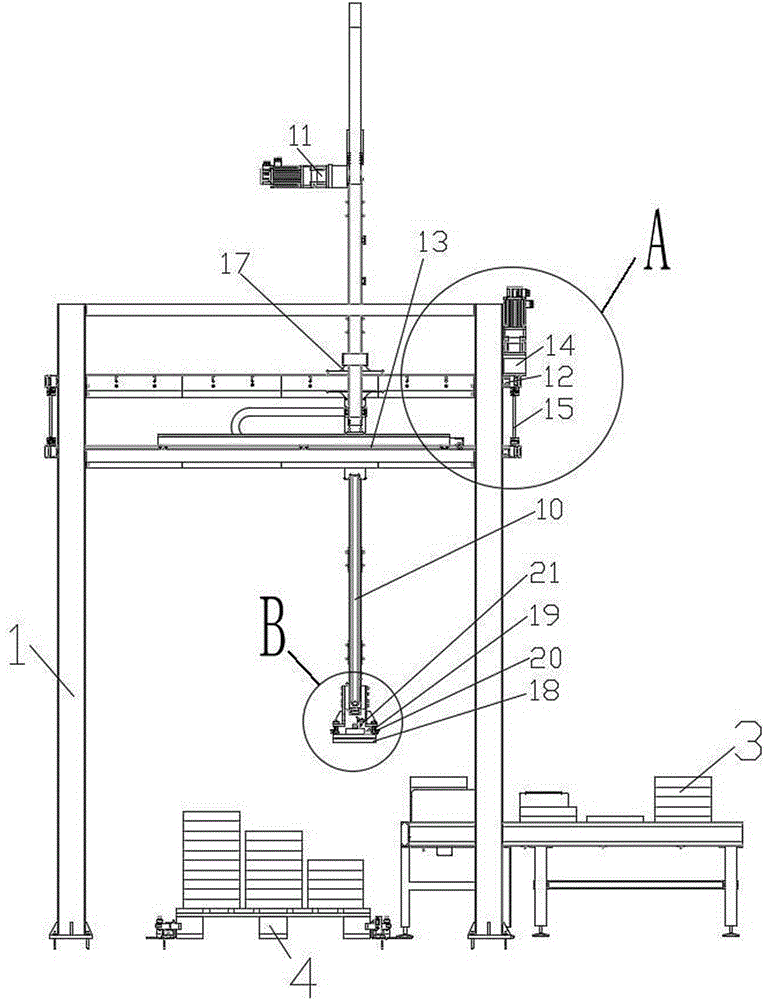

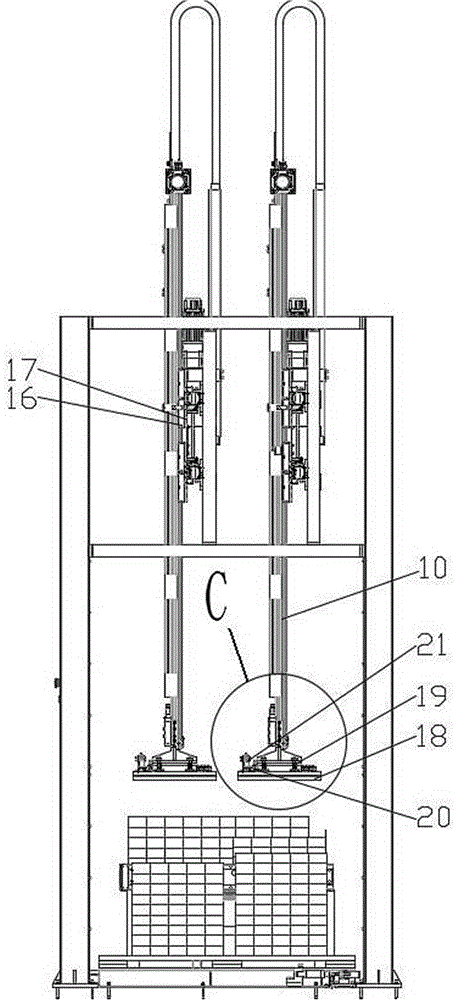

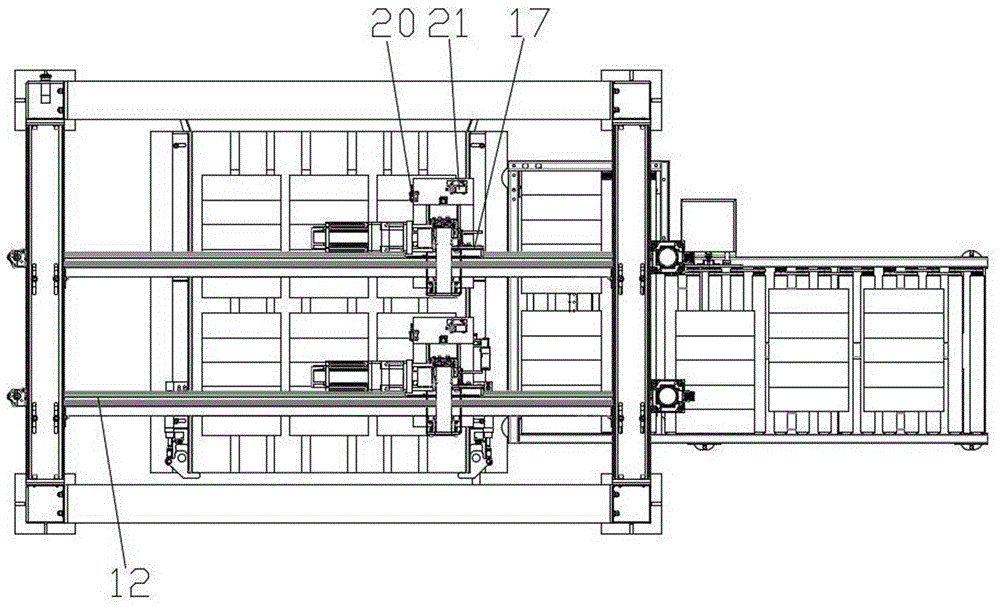

[0042] Attached below figure 1 to attach Figure 10 The present invention will be further described.

[0043] as attached figure 1 , attached Figure 4 and attached Figure 5 As shown, a palletizer includes: a frame 1, and a cargo carrying device 4 is located in the frame 1; a conveying roller table I 2, whose head end is connected with a plastic film packaging machine, and is used to pack the plastic film-packed goods 3 is conveyed in the Y-axis direction of the spatial coordinate system; the conveying roller table II 7 is located in the frame 1, and the conveying roller table II 7 is connected with the tail end of the conveying roller table I 2 for connecting the N conveying roller tables I 2 The conveyed plastic film-packed goods 3 are conveyed in the X-axis direction of the spatial coordinate system, where N is a natural number greater than or equal to 1; and N vacuum suction cups; The horizontal movement in the axial direction is respectively driven by the longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com