Pallet supplying and stacking system of automatic firework production line

An automatic production line and palletizing system technology, which is applied in the stacking of objects, de-stacking of objects, conveyors, etc., can solve problems such as low productivity, dullness, and sensitivity to chemical properties, and achieves durable equipment, long service life, The effect of high palletizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The palletizing system for the automatic production line of fireworks of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

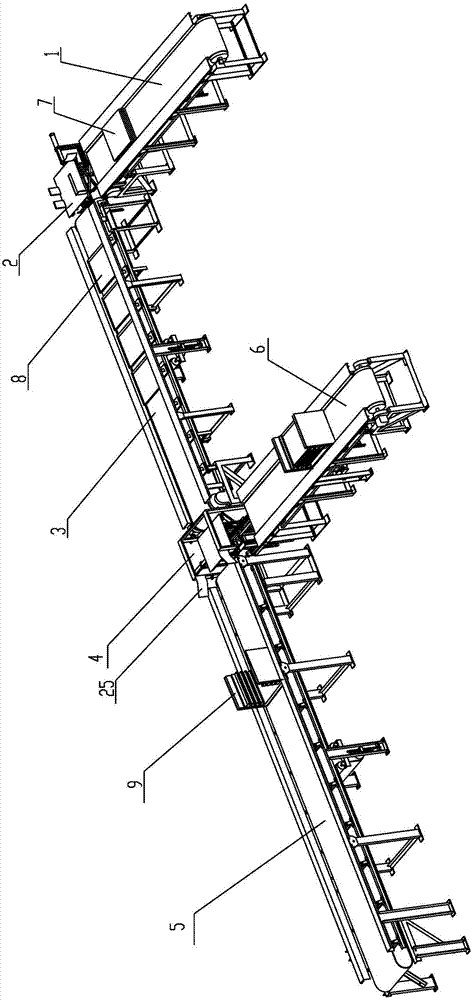

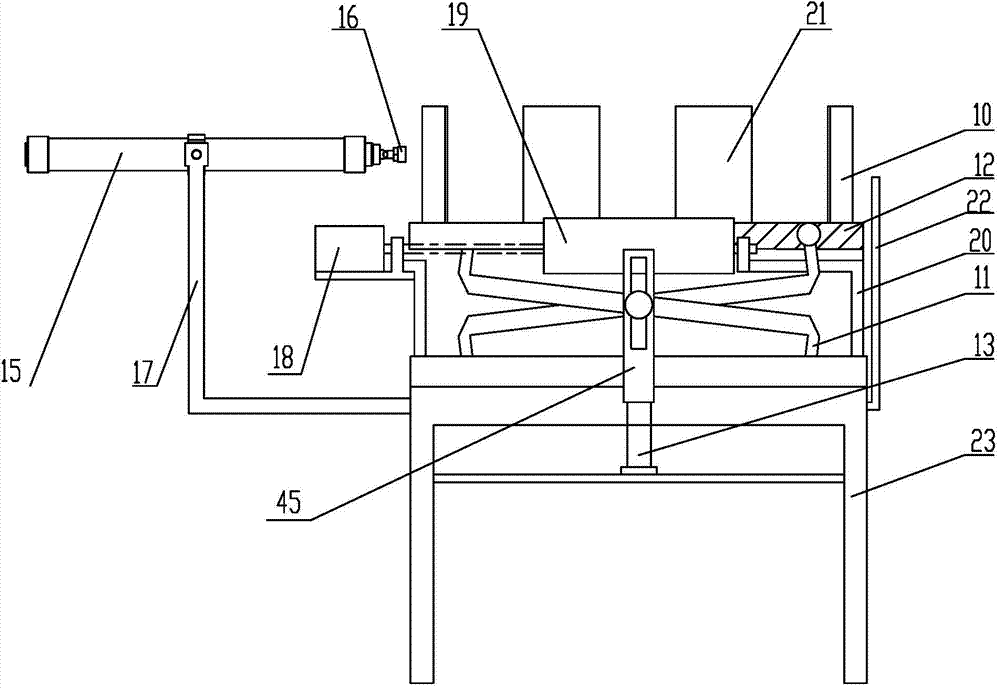

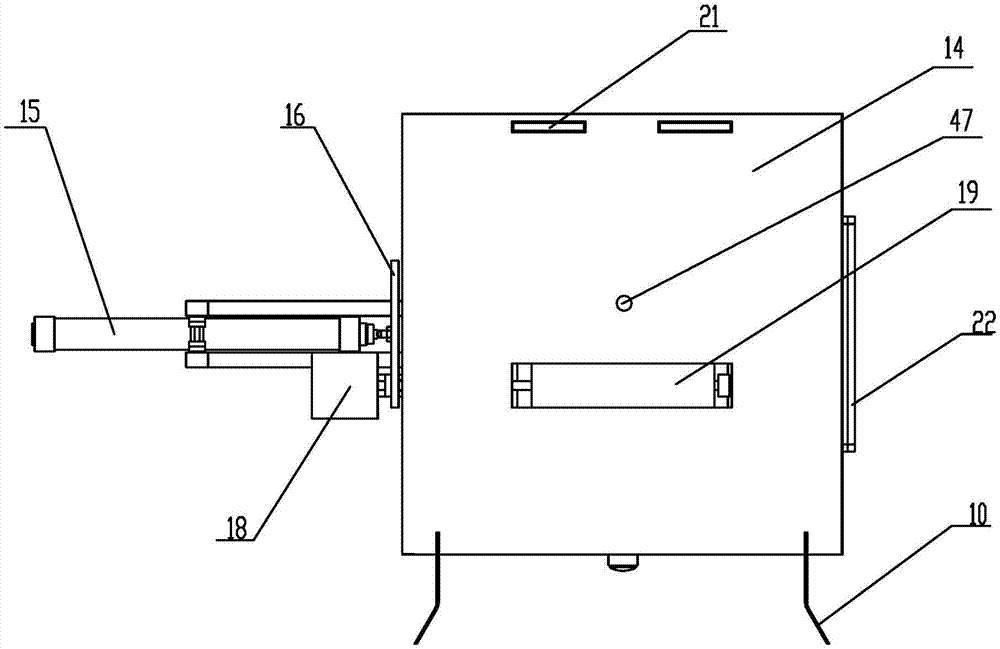

[0052] A palletizing system for automatic fireworks production line of the present invention includes: a first conveyor 1, used to receive and transmit the dried tray group 7; a second conveyor 3, used to transmit a single tray 8; The third conveyor 5 is used to transmit the rack 9; the fourth conveyor 6 is used to transport the rack 9 with the pallet 8 to the next process; it is characterized in that it is also provided with:

[0053] Disk feeder 2, located between the first conveyor 1 and the second conveyor 3, is used to receive the tray group 7 transported by the first conveyor 1, and transfer the trays 8 in the tray group 7 to the second conveyor On machine 3;

[0054] The palletizer 4 is located between the second conveyor 3, the third conveyor 5 and the fourth conveyor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com