Intelligent automatic stacking equipment and operating method thereof

An intelligent, stacking technology, applied in the field of stacking equipment, can solve the problems of low degree of automation, high work intensity and low efficiency, and achieve the effect of improving the level of automation, reducing labor costs and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

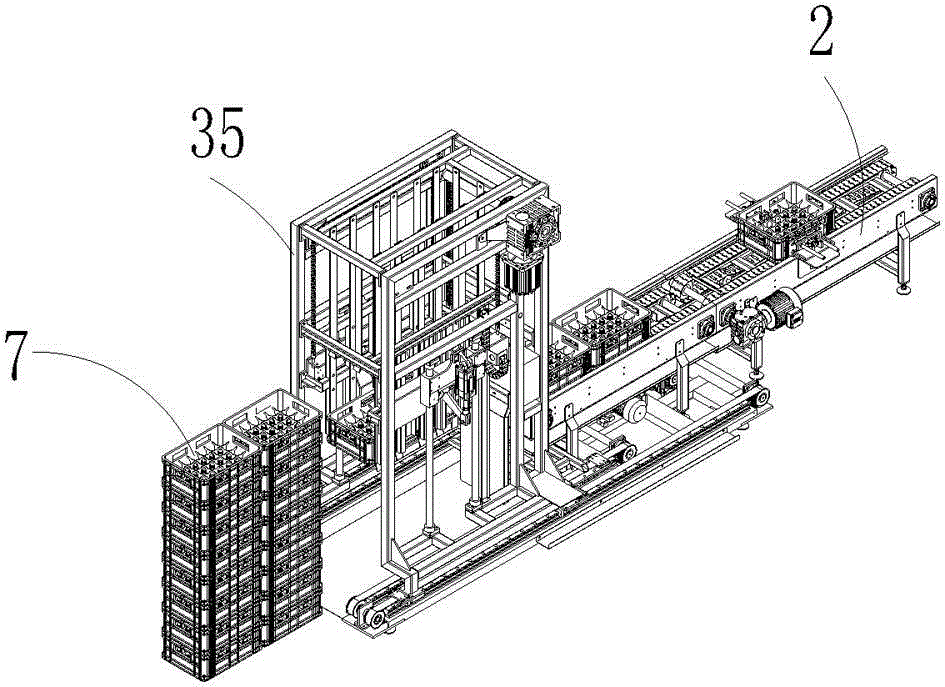

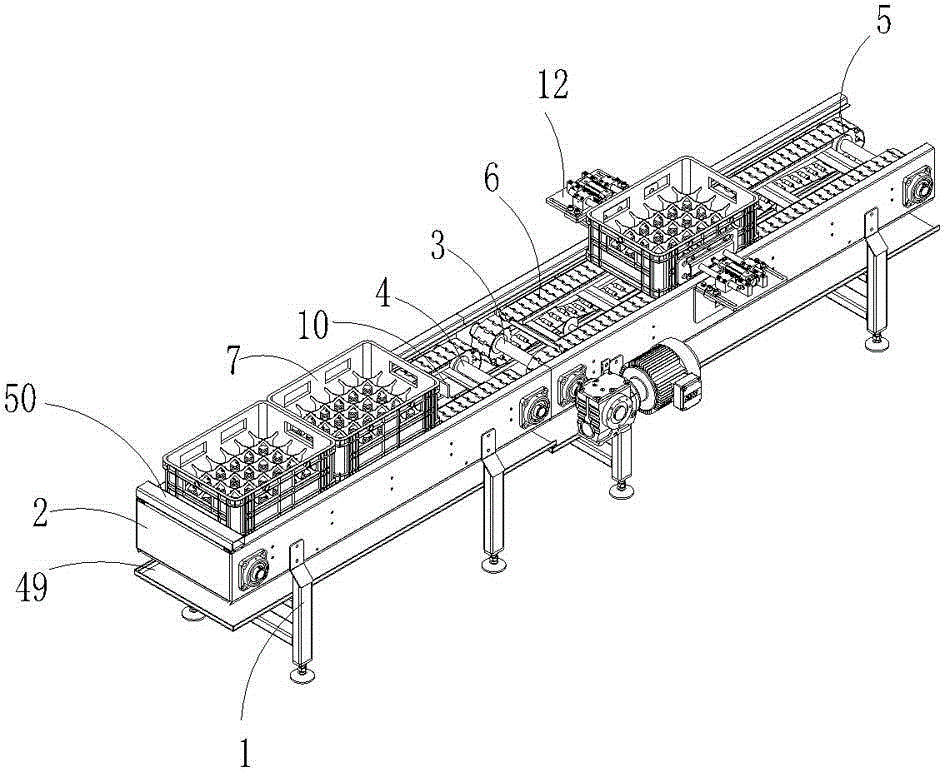

[0037] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, an intelligent automatic stacking equipment includes a conveying mechanism, a stacking mechanism and a grasping and lifting mechanism;

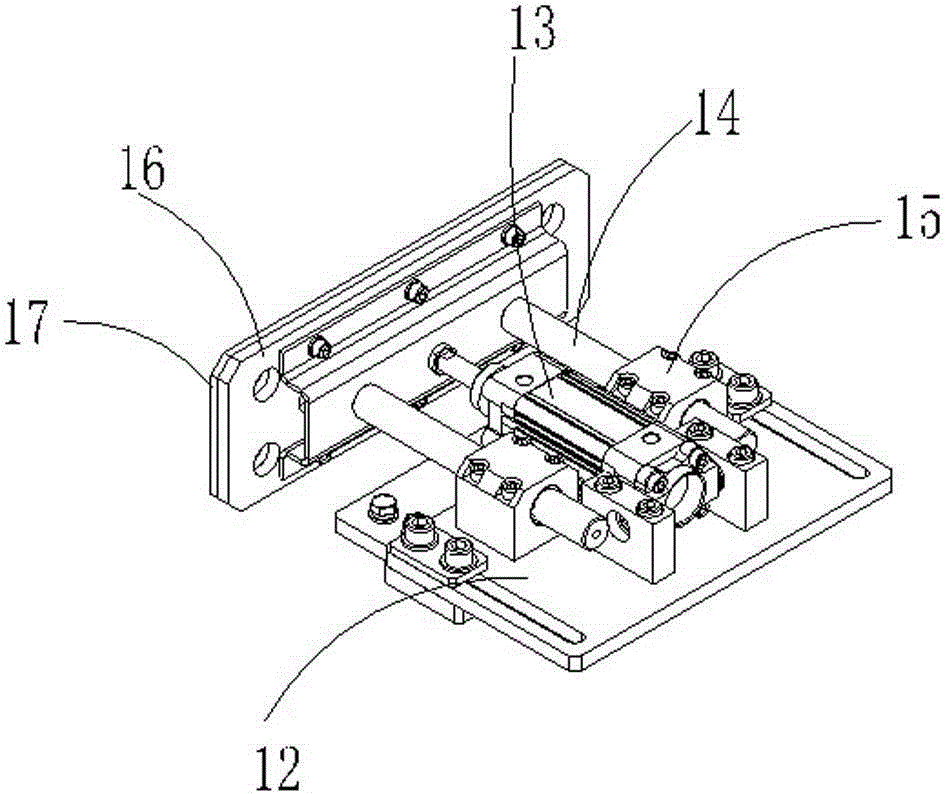

[0038] The conveying mechanism includes a conveying frame 1, the conveying frame 1 is provided with a conveying trough 2, and the conveying trough 2 is provided with at least one conveying assembly, and the conveying assembly includes a driving shaft 3 and a driven shaft 4 , the two ends of the driving shaft 3 and the driven shaft 4 are respectively provided with a sprocket 5, the sprocket of the driving shaft 3 and the sprocket of the driven shaft 4 are transmitted through the chain plate 6, and the chain plate 6 is provided with a turnover box 7, the drive shaft 3 is driven by 8 phases of the conveying motor, the conveying assembly is provided with a box assembly, and the outer wall of the entrance of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com