Half-offline mixed stacking method and system as well as robot

A hybrid palletizing and palletizing technology, applied in the field of systems, robots, and semi-offline hybrid palletizing methods, can solve the problems of low pallet utilization rate, poor palletizing stability, and increased palletizing cost, and achieve high pallet utilization rate and low cost. Easy to roll and reduce the cost of palletizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

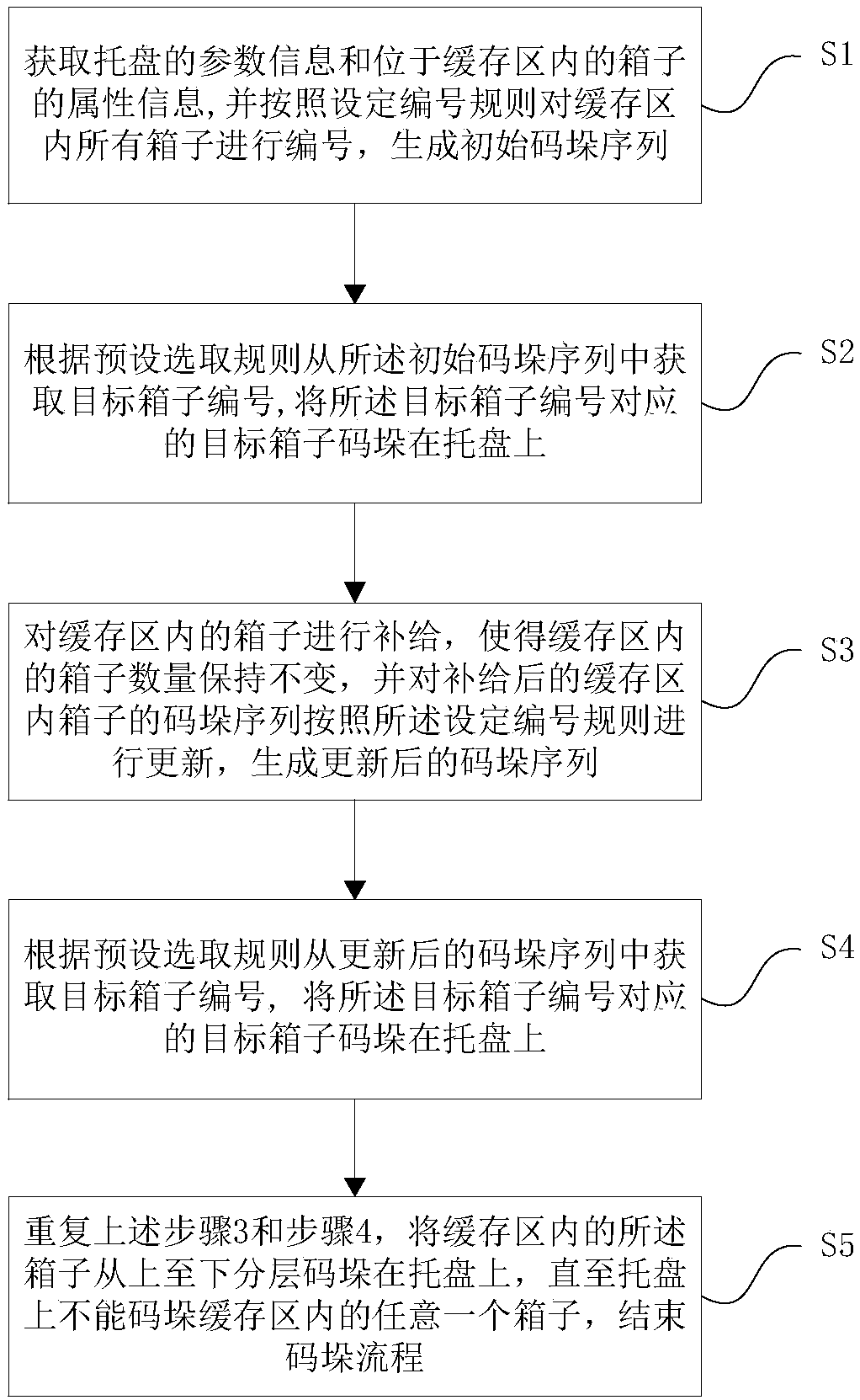

[0060] Such as figure 1 Shown, a kind of semi-offline mixed stacking method comprises the steps:

[0061] Step 1: Obtain the parameter information of the pallet and the attribute information of the boxes in the buffer area, and number all the boxes in the buffer area according to the set numbering rules to generate the initial palletizing sequence;

[0062] Step 2: Obtain the target box number from the initial stacking sequence according to the preset selection rules, and stack the target box corresponding to the target box number on the pallet;

[0063] Step 3: Replenish the boxes in the buffer area so that the number of boxes in the buffer area remains unchanged, and update the stacking sequence of the boxes in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com