Acoustic board stacking production line and method used for high-speed rail

A technology for sound-absorbing panels and production lines, which is applied in the stacking of objects, de-stacking of objects, conveyor objects, etc., can solve the problems of low degree of automation, low production efficiency, and high labor costs, and reduce labor intensity and production costs. , Guarantee the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: A palletizing production line of sound-absorbing panels for high-speed rail.

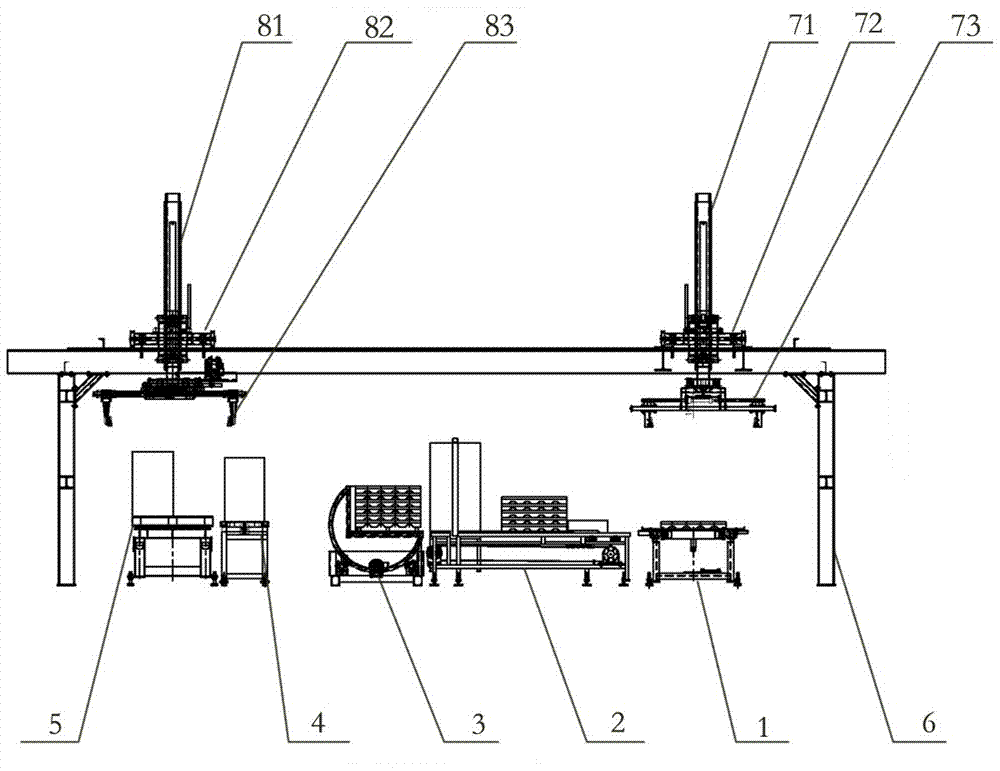

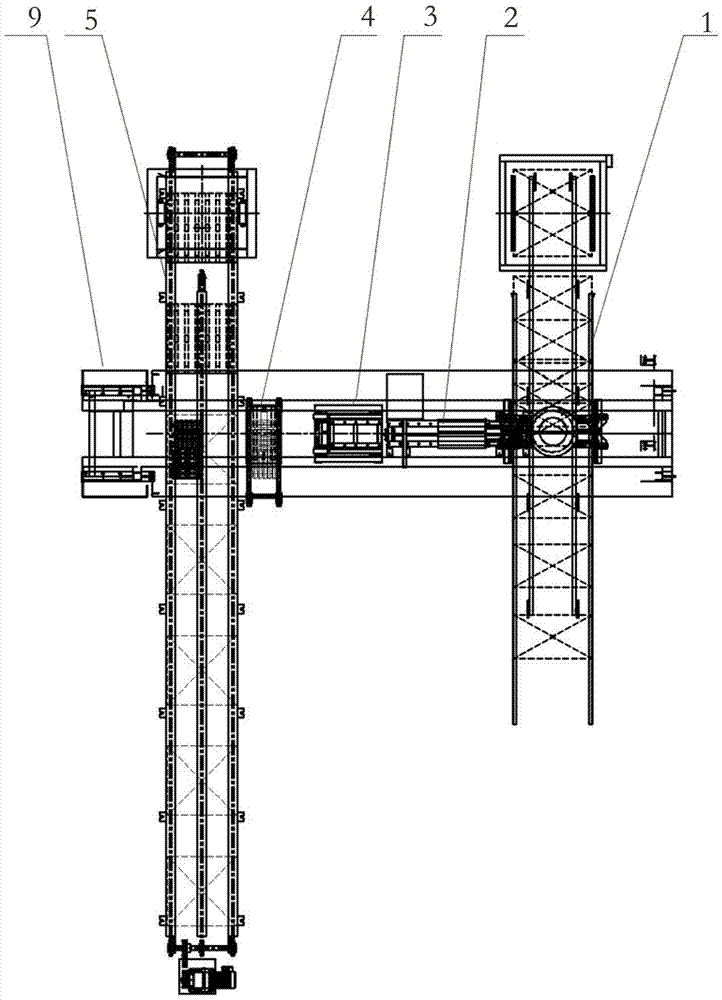

[0044] Such as Figure 1~Figure 4As shown, the high-speed rail sound-absorbing board palletizing production line of the present invention includes a conveyor 1 for conveying sound-absorbing board pallets, a packing machine 2 for bundling and packing a specified number of sound-absorbing boards into small stacks 10 of sound-absorbing boards, It is used to turn the sound-absorbing board small stack 10 from the horizontal placement to the vertical placement and put it into the turning machine 3. It is used to put the specified number of sound-absorbing board small stacks of 10 yards into neat semi-finished stacks and put them into the adjustment workbench 4. Use It is used to put the specified number of semi-finished product stacks into finished product stacks and transport the finished product stacks to the designated position and put them into the finished product conveyor 5. It is ...

Embodiment 2

[0047] Embodiment 2: A method for stacking sound-absorbing panels for high-speed rail.

[0048] Such as Figure 1~Figure 4 As shown, a high-speed rail sound-absorbing board stacking method includes the following steps:

[0049] a. Install sound-absorbing panel palletizing production line:

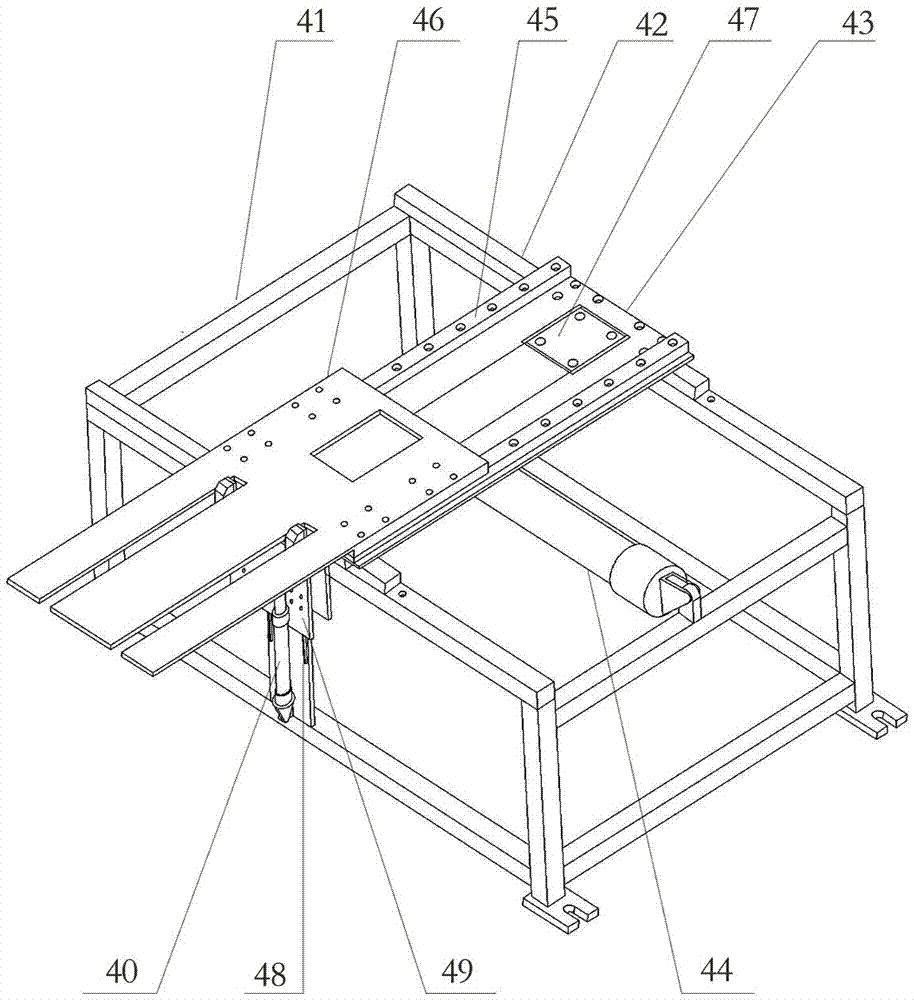

[0050] Install conveyor 1, baler 2, turner 3, adjustment workbench 4 and finished product conveyor 5, connect baler 2 to the delivery area of conveyor 1, and connect turner 3 to the delivery end of baler 2 For docking, the adjustment position workbench 4 is placed on the delivery side of the turning machine 3, and the finished product conveyor 5 is attached to one side of the adjustment position workbench 4. The adjustment workbench 4 in the step a is a telescopic workbench capable of stretching back and forth, effect stretching and stretching up and down.

[0051] Install the stacking device: install the first pick-and-place mechanism and the second pick-and-place mechanism on the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com