Ceramic tile palletizing apparatus

A stacking device and ceramic tile technology, applied in the field of ceramic manufacturing, can solve the problems of high labor intensity, restricting the production process, low production efficiency, etc., and achieve the effects of simple and reliable operation, simple structure, convenient use and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

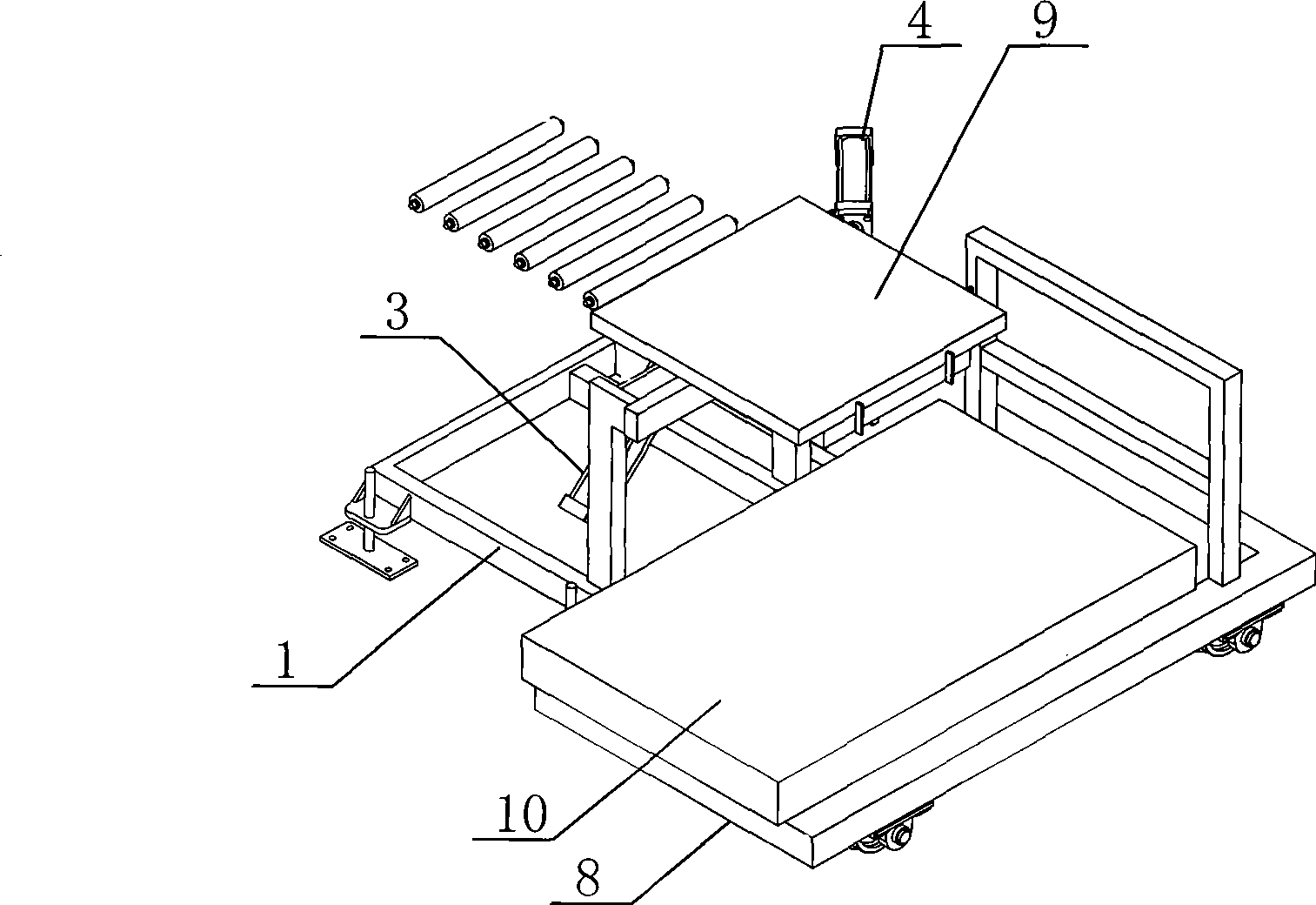

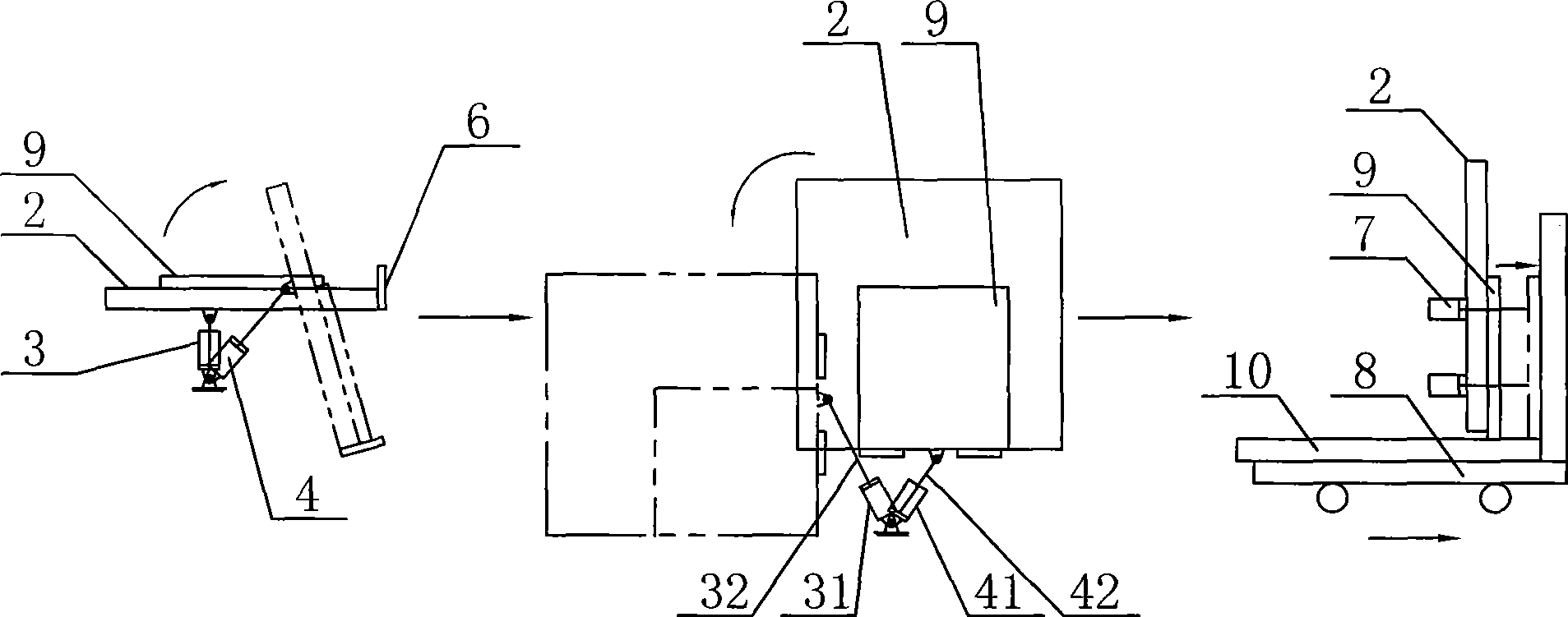

[0023] like figure 2 As shown, a tile palletizing device of the present invention includes a stand 1, a tray 2 for supporting tiles, an overturning device 3 for turning the tray 2 from the horizontal direction to the vertical direction, and turning the tray 2 in the vertical direction. Rotating rotating device 4, the bottom of the tray 2 is provided with a supporting base 5 for supporting, the supporting base 5 is flexibly connected with the upper beam of the stand 1, the supporting base 5 is connected with the output end of the turning device 3 and the rotating device 4 All are movably connected. In this embodiment, the tray 2 is a plate-shaped tray.

[0024] like Figure 4 As shown in FIG. 6 , the support seat 5 is rectangular, and its two right-angle sides are correspondingly arranged at the bottom edge position of the front side of the tray 2, and the right-angle vertex of the support seat 5 is movably connected to the top of the stand 1. Outer end, the end of the longit...

Embodiment 2

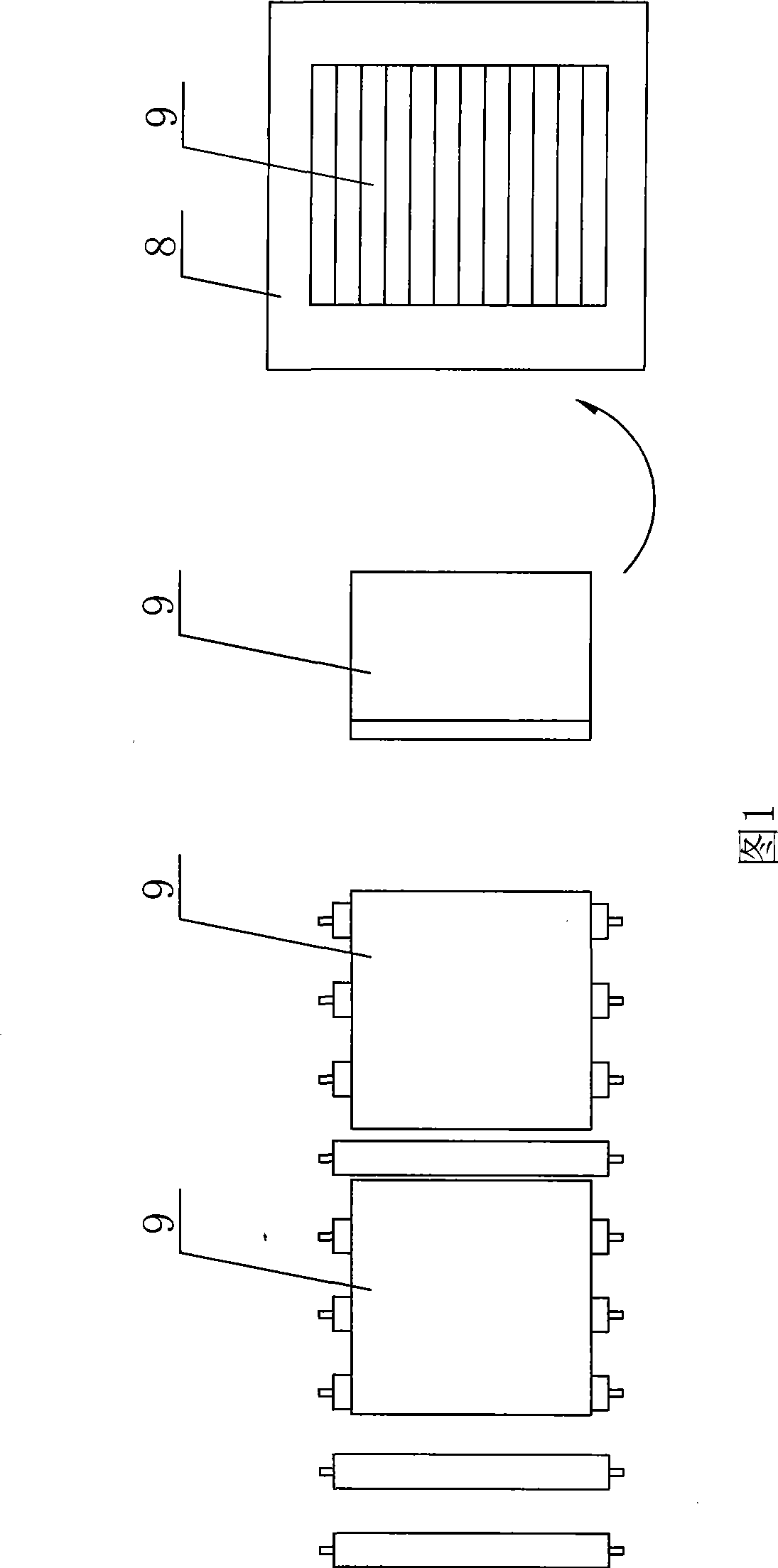

[0031] The structure of this embodiment is basically the same as that of the first embodiment above, and the difference is that: Figure 7 As shown, the pallet 2 is a support frame composed of several support rollers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com