Full-automatic carton stacking production line

A production line, fully automatic technology, applied in the field of carton palletizing, can solve the problems of difficult disassembly, difficult long-distance transportation, and high maintenance costs, and achieve the effect of convenient later maintenance and repair, convenient long-distance transportation, and shortened positioning time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

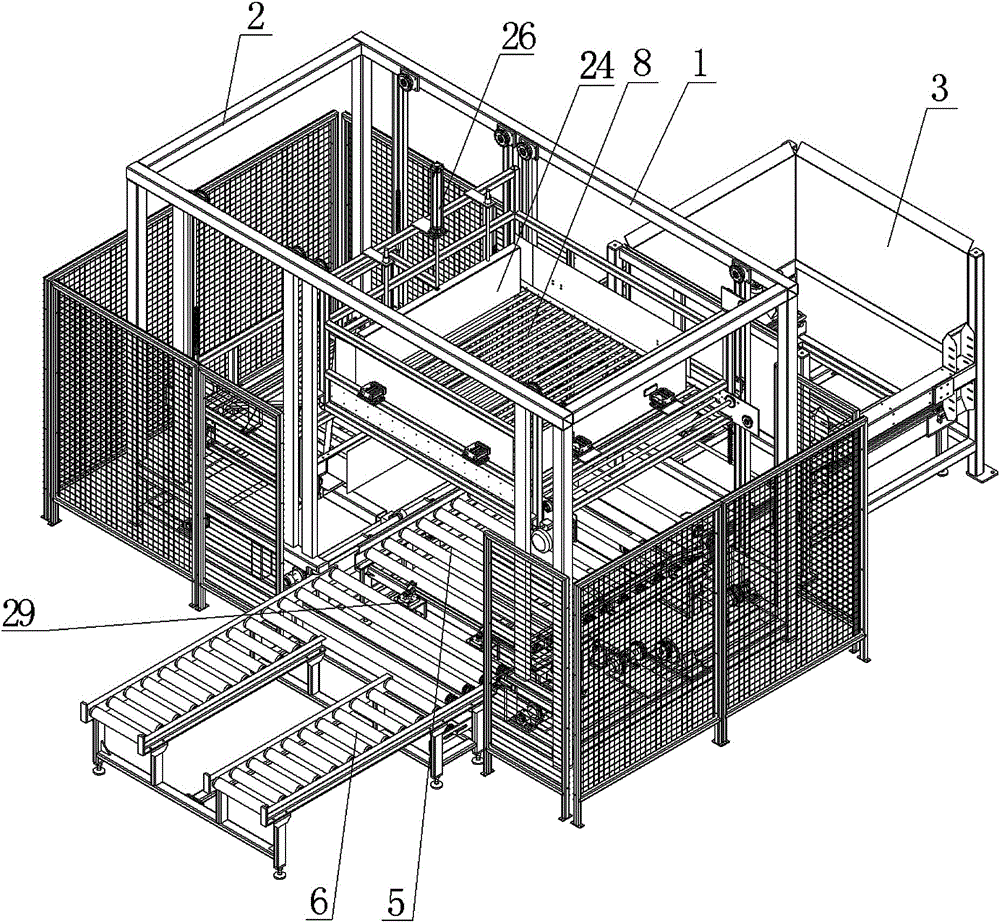

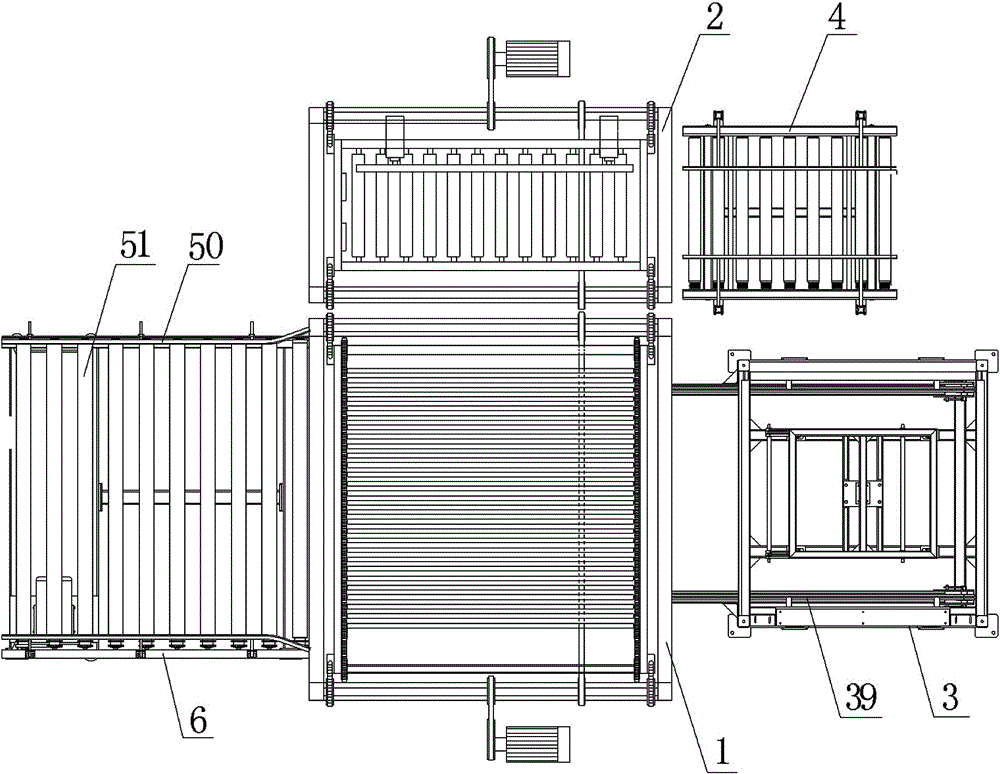

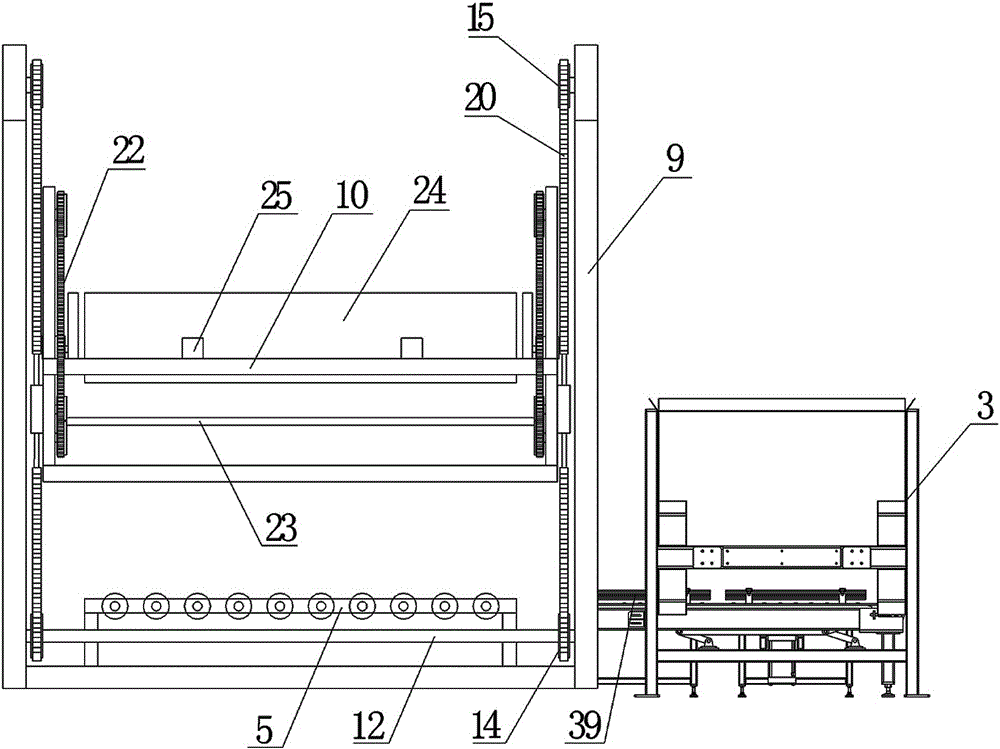

[0033] Such as Figure 1~12 Shown, a kind of full-automatic carton palletizing production line, it comprises palletizer 1, box pusher 2, tray storehouse 3, case-feeding roller table 4, pile conveying mechanism 5 and finished product pile conveying device 6, described palletizing Machine 1 is made up of elevating mechanism I7 and curtain drawing mechanism 8, and elevating mechanism I7 is made up of main frame 9, auxiliary frame 10, motor 11, driving shaft 12, driven shaft 13, lower sprocket wheel 14, upper sprocket wheel 15, driving chain wheel 16 and driven sprocket 17, the sub-frame 10 is set in the main frame 9, the four corners of the sub-frame 10 are provided with fixed blocks 18, the driving shaft 12 and the driven shaft 13 are both rotatably mounted on the main frame At the lower end of the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com