Special-shaped cigarette stacking device and stacking method

A stacking device and a technology for special-shaped smoke, which are applied in the stacking, transportation and packaging of objects, and the destacking of objects, can solve the problems of increased labor costs, heavy stacking workload, and low production efficiency, and achieve grasping High efficiency, improve stacking efficiency, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

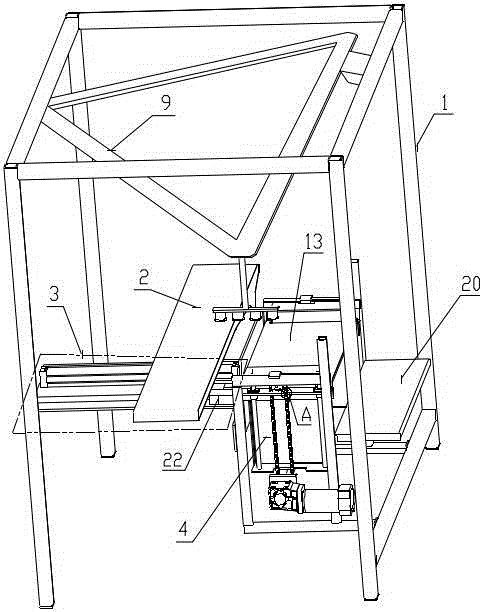

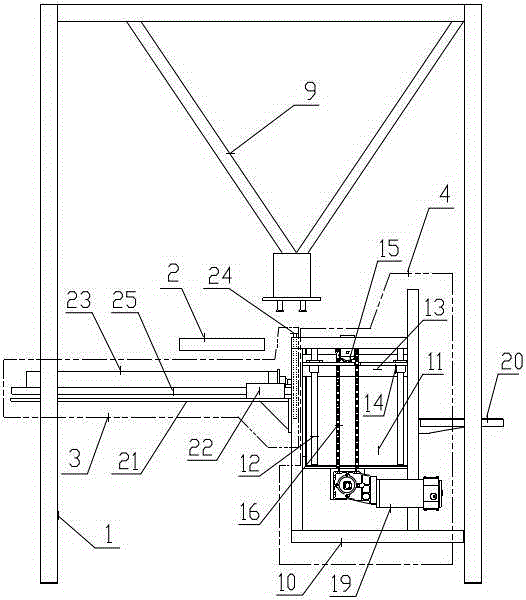

[0021] Example 1. A special-shaped cigarette stacking device, composed of Figure 1-5 As shown, including a bracket 1, a detection transmission device 2 is provided on the support 1, a grasping device is provided above the detection transmission device 2, a push device 3 is provided below the detection transmission device 2, and a stacking unit 4 is provided beside the push device 3; The detection and conveying device 2 includes a conveyor belt 5, on which a projection area 6 is provided, and a palletizing area 7 is provided beside the projection area 6; a projection camera 8 is provided at the projection area 6.

[0022] The stacking method used by the aforementioned special-shaped cigarette stacking device is:

[0023] a, the special-shaped smoke is transported to the conveyor belt 5 of the detection transmission device 2, when passing through the projection area 6 of the conveyor belt 5, the projection camera 8 in the projection area 6 collects the projected area of each...

Embodiment 2

[0026] Example 2. A special-shaped cigarette stacking device, composed of Figure 1-5 As shown, including a bracket 1, a detection transmission device 2 is provided on the support 1, a grasping device is provided above the detection transmission device 2, a push device 3 is provided below the detection transmission device 2, and a stacking unit 4 is provided beside the push device 3; The detection and conveying device 2 includes a conveyor belt 5, on which a projection area 6 is provided, and a palletizing area 7 is provided beside the projection area 6; a projection camera 8 is provided at the projection area 6.

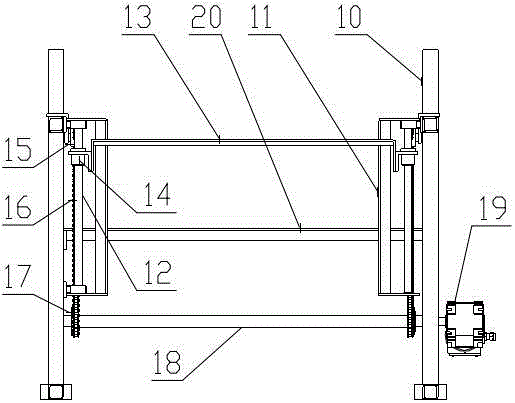

[0027] The aforementioned grabbing device is a spider manipulator 9; the stacking unit 4 includes a fixed mount 10, and both sides of the fixed mount 10 are provided with a guide plate 11, and the guide plate 11 is provided with a packing platform 20, and the guide plate 11 is provided with Lifting guide shaft 12, stacking platform 13 is provided between two guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com