Mechanical arm paw for robot palletizer and manufacturing method of mechanical arm paw

A palletizing robot and mechanical gripper technology, applied in the field of packaging and transfer equipment, can solve the problems of increasing labor costs, inability to grasp, and the weight of the gripper is heavy, and achieves high transfer and palletizing efficiency, wide application range, and high versatility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

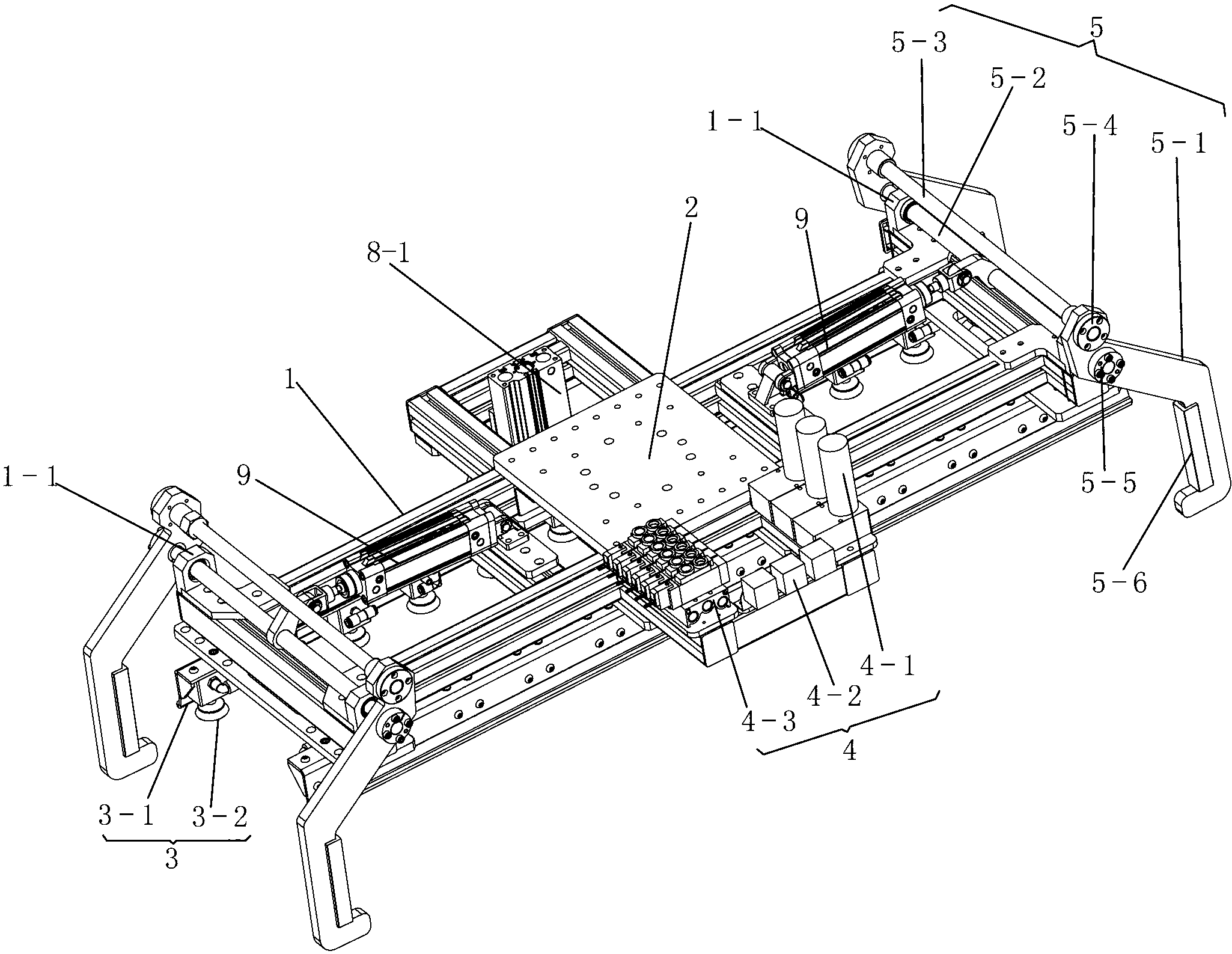

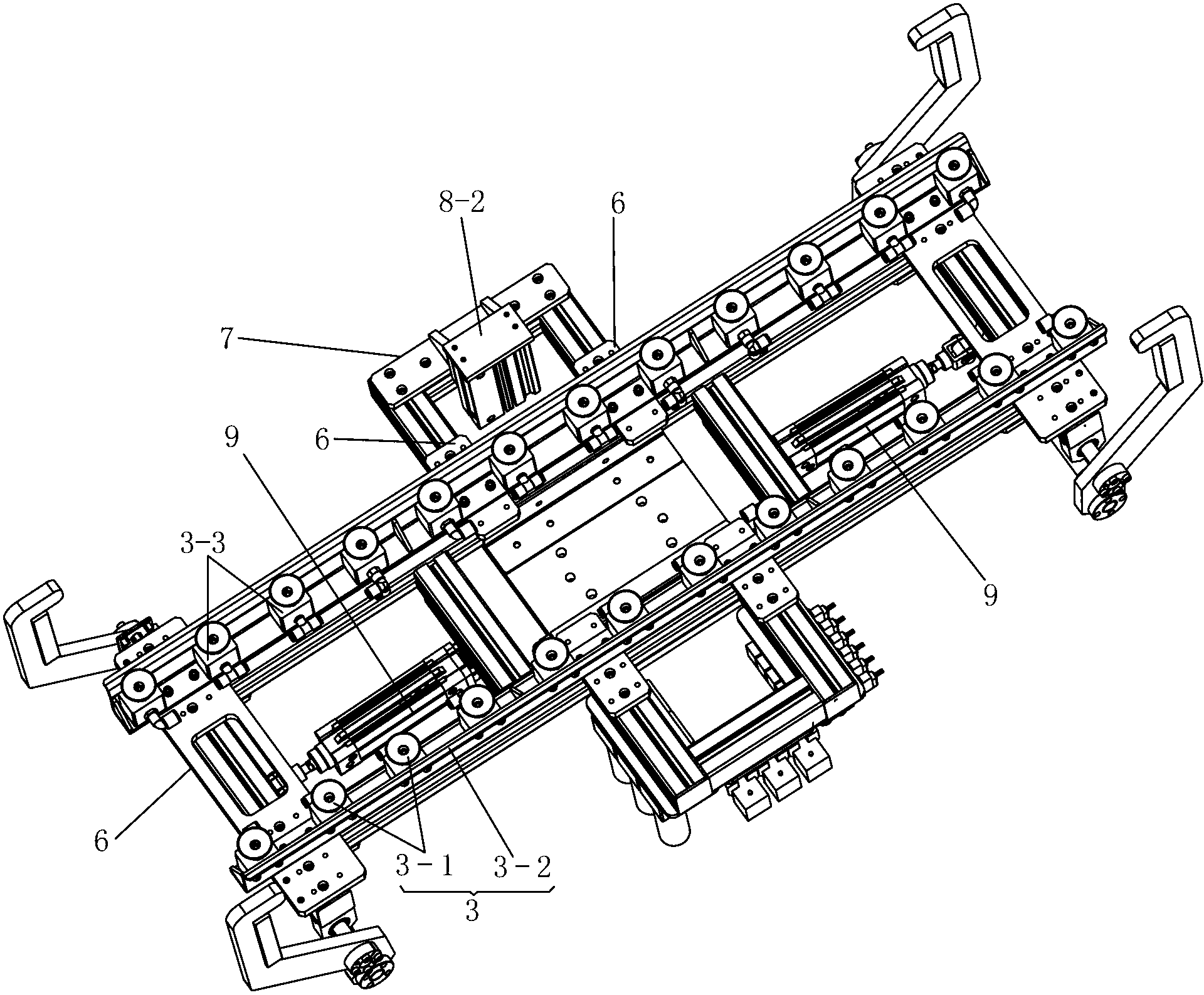

[0027] See Figure 1-2 , the manipulator claw for palletizing robot of the present invention, comprises: the connection flange 2 that links to each other with the mechanical arm of palletizing robot, the installation frame 1 that links to each other with this connection flange 2 bottom surfaces, this installation frame 1 is rectangular, is located at installation The brackets on both sides of the middle part of the frame 1 are connected to the suction cup device 3 on the installation frame 1 through a plurality of mounting plates 6, the vacuum control device 4 on one bracket, and the height detection device on the other bracket 7 , the grasping device 5 installed symmetrically at both ends of the installation frame 1 , and the cylinder drive device 9 provided on the installation frame 1 .

[0028] The suction cup device 3 includes: a pair of suction cup connecting baffles 3-1 arranged on both side edges of the installation frame 1, ten to twenty suction cup mounting seats 3 ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com