Control method of palletizing robot based on formula

A technology of a palletizing robot and a control method, which is applied in the field of formula-based palletizing robot control, can solve the problems of complex operation of the robot palletizing system and increase the number of palletized products, etc., to improve the degree of automation and the simplicity of operation. Production efficiency, the effect of solving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

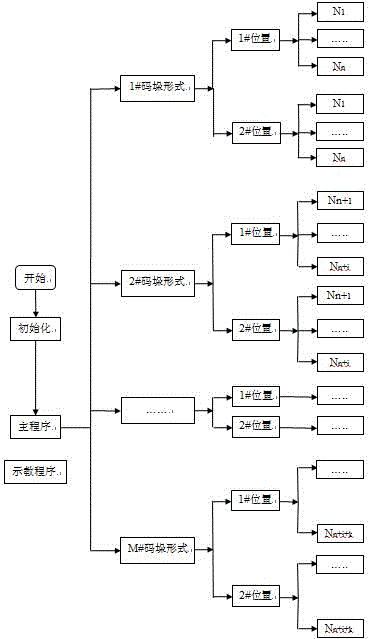

[0030] The invention discloses a formula-based palletizing robot control method, including

[0031] The teaching steps of teaching key teaching points to the robot;

[0032] The input steps of inputting the palletizing form data, palletizing position data, and palletizing formula data into the robot control system;

[0033] Select the selection steps of palletizing position, palletizing form and palletizing formula from the control system;

[0034] According to the data obtained in the above steps, the algorithm steps of using the palletizing algorithm to obtain the actual palletizing position.

[0035] This robot uses a certain carton in each palletizing type as the teaching reference. After the teaching is completed, for the cartons of the same palletizing type, you only need to input the corresponding parameters such as product size and number of palletizing layers. , the automatic palletizing of the robot can be realized.

[0036] The teaching steps are as follows:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com