Tipcart for controlling small bucket to automatically load objects by using member

A technology for automatic loading and dump trucks, applied in the field of dump trucks, can solve the problems of high labor costs, achieve simple structure, wide application, and solve the effects of labor and loading and unloading costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

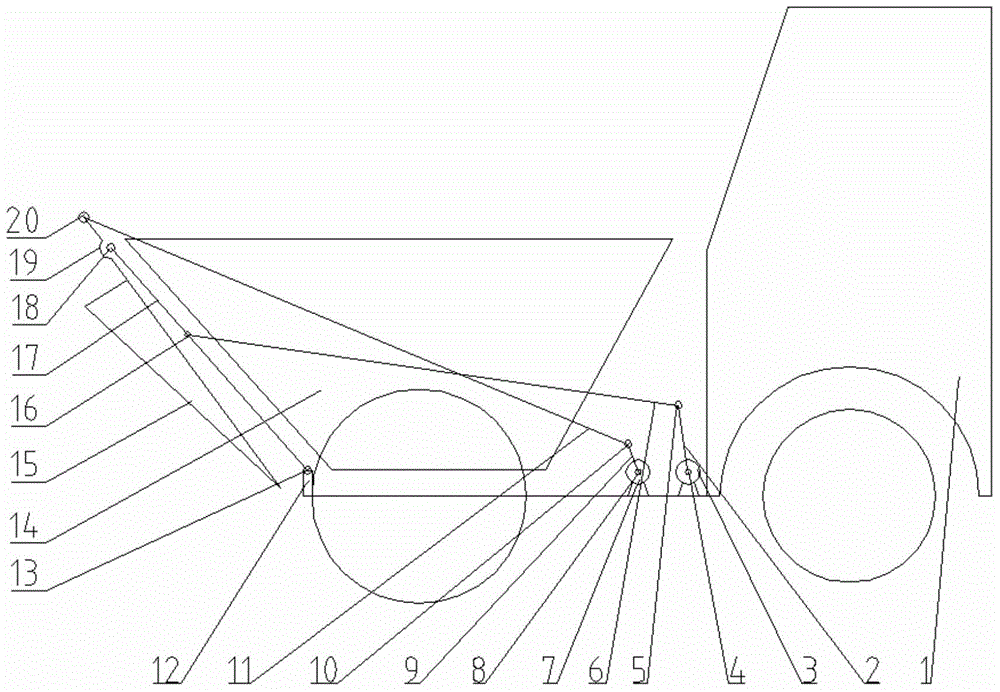

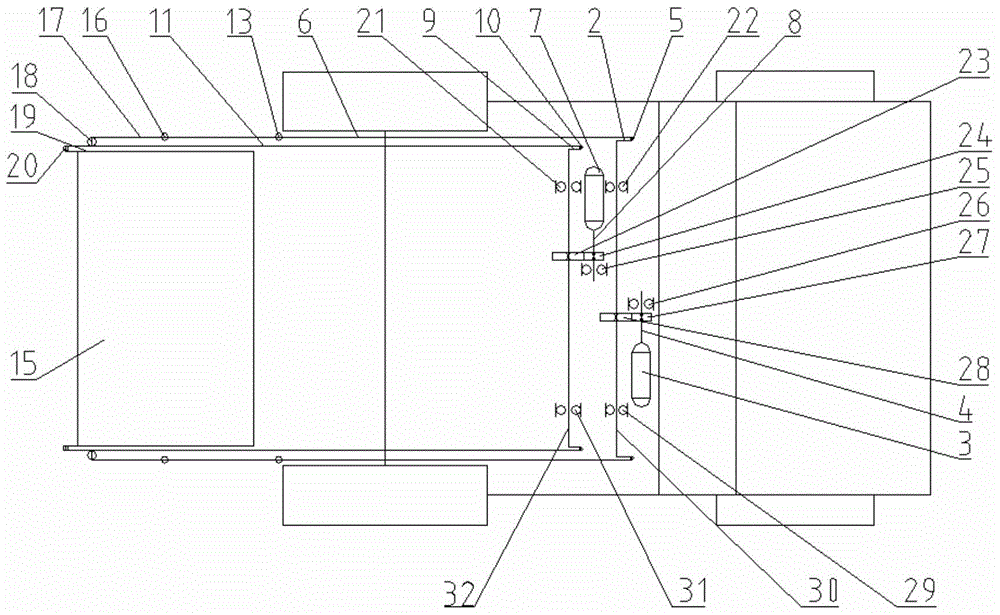

[0011] Below in conjunction with accompanying drawing, the present invention will be further described:

[0012] The dump truck of the present invention comprises a car body 1 and a large bucket 14 with running wheels at the bottom, the large bucket 14 is installed on the car body 1, and the front end of the large bucket 14 is provided with a small bucket 15, and the small bucket 15 is fixed on On the fourth connecting rod 19 on both sides of the large bucket 14, the top of the fourth connecting rod 19 is hinged with an end of the third connecting rod 17 through the fifth hinge hole 18, and the top of the fourth connecting rod 19 is connected to the second connecting rod. Rod 11 is hinged through the sixth hinge hole 20, and the bottom end of the third connecting rod 17 is hinged with the fixed block 12 on the vehicle body 1 through the third hinged hole 13. The fixed block 12 is welded on the vehicle body, and the third connecting rod The middle part of 17 is hinged with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com