Single-shaft automatic feeding and discharging wall cloth processing device

A technology of automatic loading and unloading, processing device, applied in the field of wall covering production, can solve the problem of not having automatic loading and unloading function and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

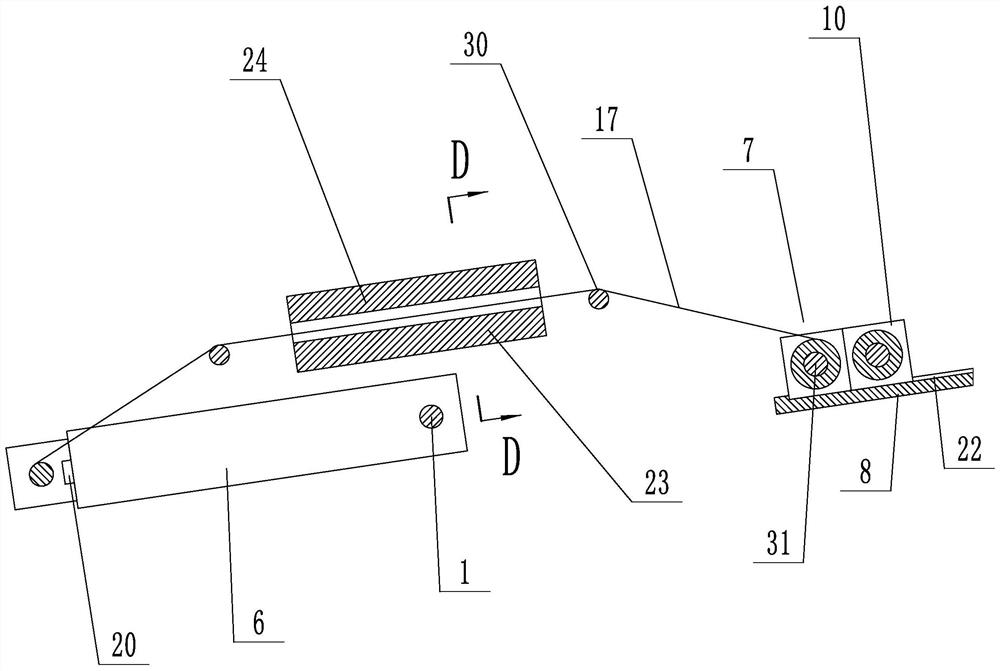

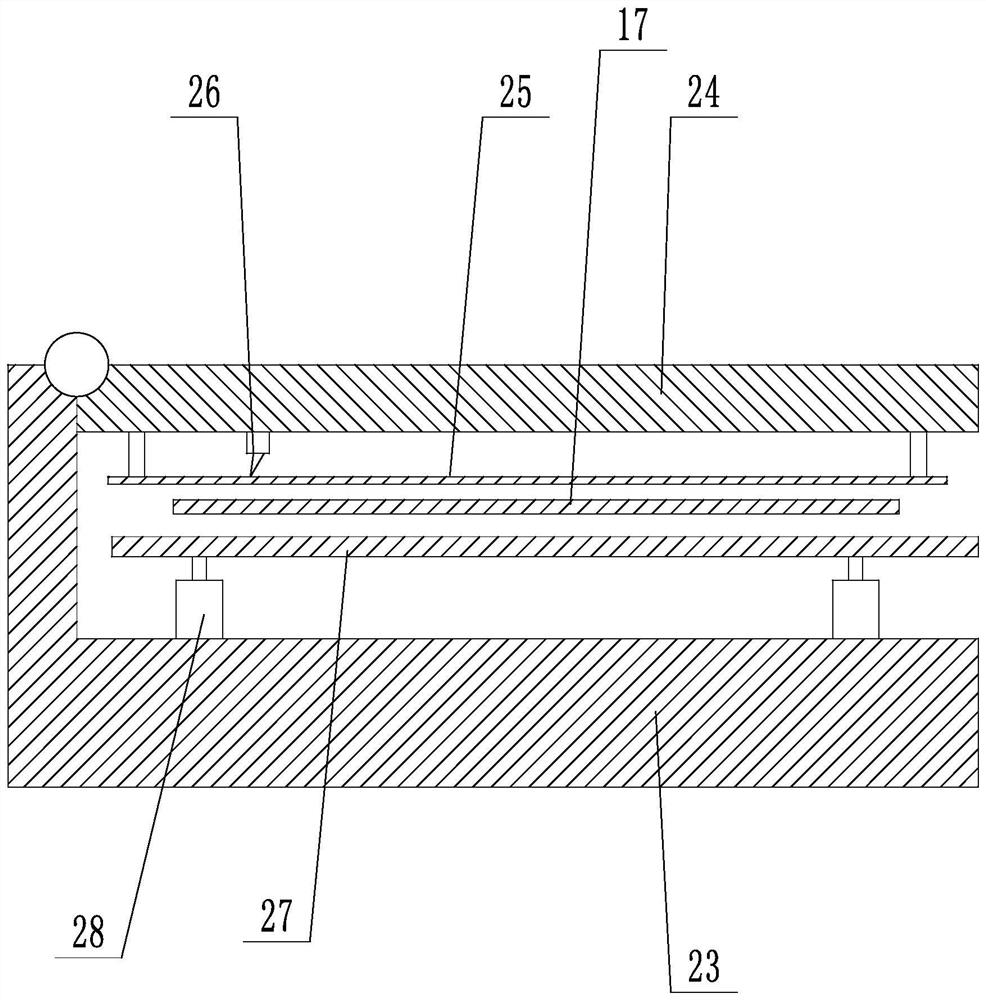

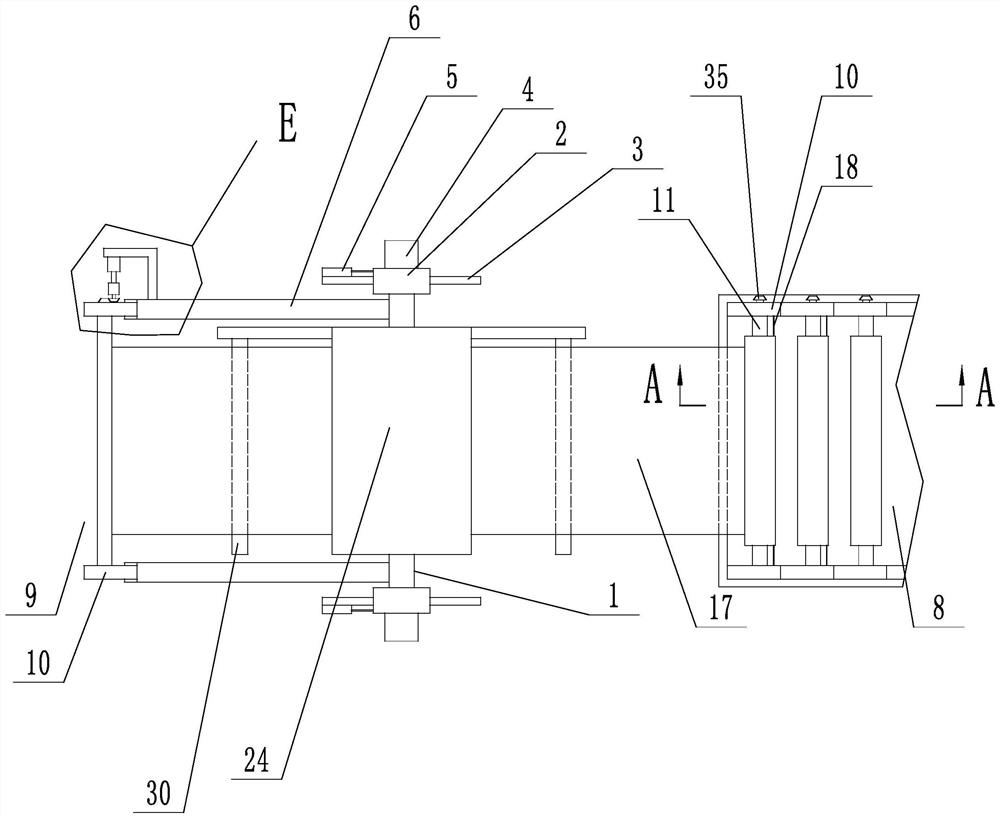

[0033] see Figure 1 to Figure 16 , a single-axis automatic loading and unloading wall covering processing device, comprising a rotating shaft 1, a slider 2 located at both ends of the rotating shaft 1, a slide rail 3 for sliding the slider 2, a first motor 4 for rotating the rotating shaft 1, The first electric cylinder 5 of the sliding sliding block 2, the support mechanism located on the rotating shaft 1 to support the wall covering roller 7, the screen printing device located above the rotating shaft 1 to screen the wall covering 17, to support the winding to be processed The supporting platform 8 of the wall cloth roller 7 of the wall cloth 17, the discharge conveyor belt 21;

[0034] The end of the wall covering 17 is provided with a connecting rod 18;

[0035] The wall covering roller 7 includes a main shaft 9 for wrapping the wall covering 17, a bracket 10 rotatably connected to both ends of the main shaft 9, and a connecting rod 18 corresponding to the adjacent wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com