Bearing pad double-sided chamfering machine with automatic loading and unloading function and its application method

An automatic loading and unloading and chamfering machine technology, applied in metal processing and other directions, can solve the problems of semi-automatic operation, increased product quality self-inspection frequency, product update, inconvenient equipment maintenance, overall control level and precision gap, etc., to avoid safety Hidden dangers and accidental errors, overall structure simplification, and the effect of stable speed control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

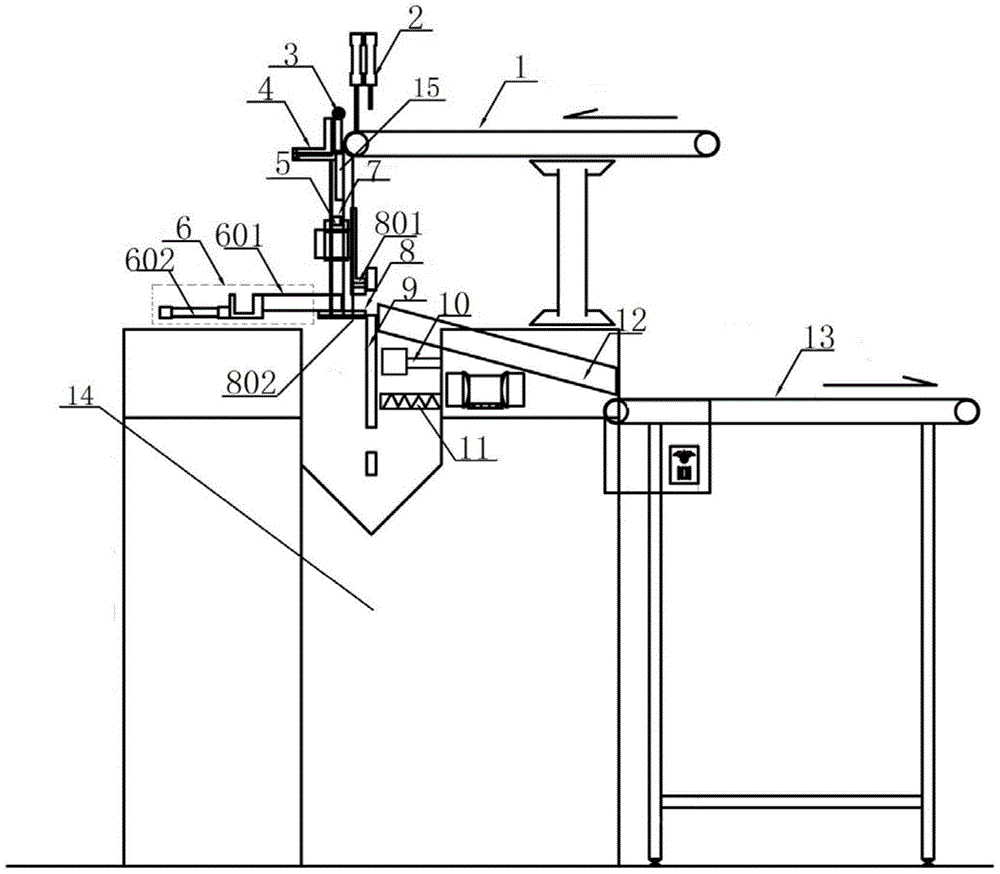

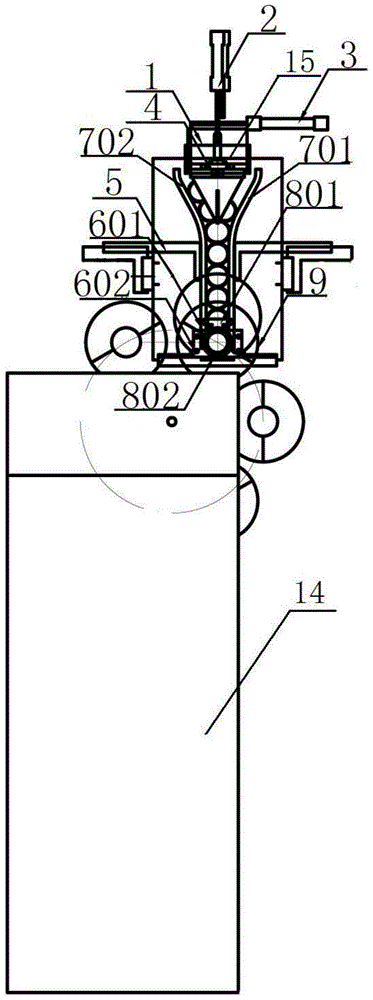

[0039] This embodiment provides a bearing pad double-sided chamfering machine with automatic loading and unloading functions, the structure is as follows figure 2 and 3 Shown, comprise the machine tool 14 that is arranged horizontally and be provided with motor in the machine tool 14, the rotating shaft of motor horizontally stretches out machine tool 14 and interferes with the center through hole of a vertically arranged station tire mold 9, one of machine tool 14 The side is also provided with a pressing device 10 and a two-end surface processing device 11 in turn, and six stations are arranged at equal intervals along the circumferential direction on the station tire mold 9, and a pushing device 6 is also horizontally arranged on the machine tool 14, and the pushing device 6 The pushing direction is towards the station tire mold 9 and is perpendicular thereto;

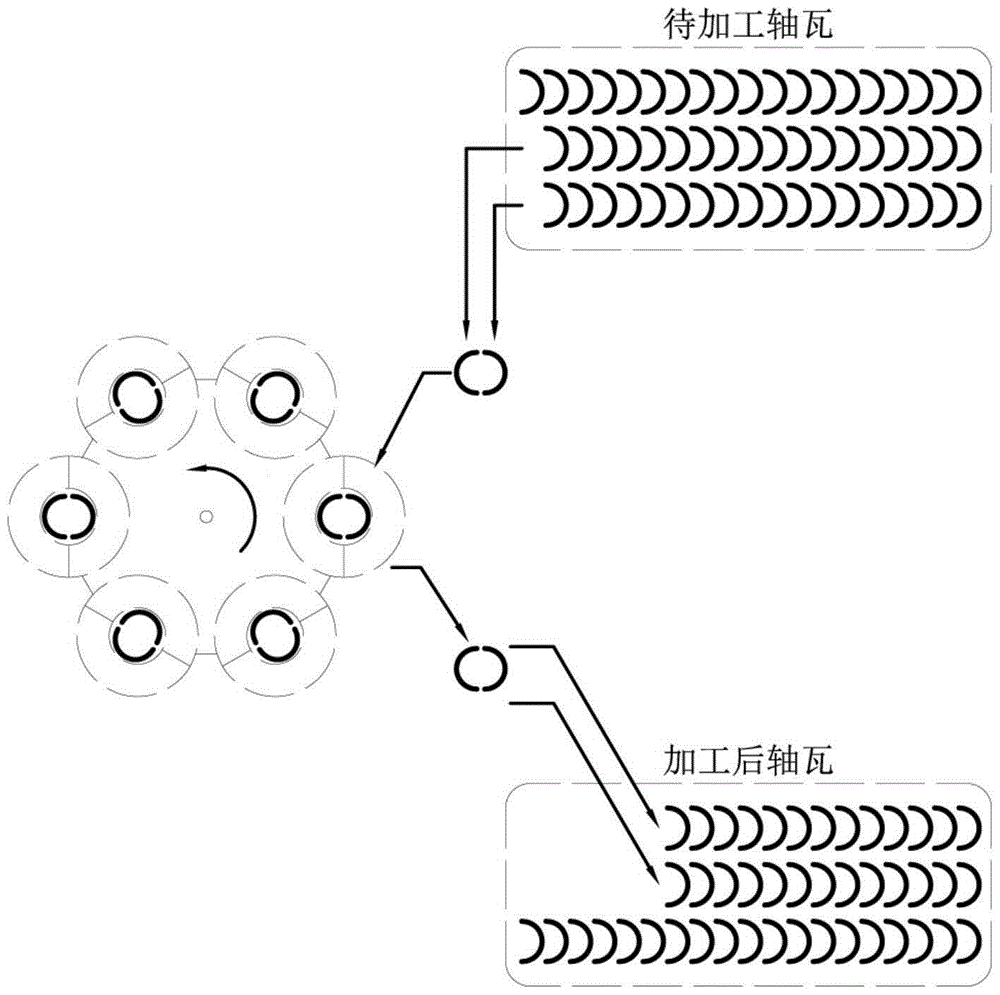

[0040] In the static state, the positions of the three consecutive stations on the station tire mold 9 are in s...

Embodiment 2

[0048] This embodiment provides the usage method of the bearing pad double-sided chamfering machine with automatic loading and unloading function in the above-mentioned embodiment 1, the process is as follows Figure 4 shown, including the following steps:

[0049] Step (1): In the initial state, all equipment is in the prohibited state, and the half-arc-shaped bearing bush blanks are arranged in a row on the feeding conveying device 1, and the arc-shaped opening of the bearing bush blanks faces the conveying direction of the feeding conveying device 1, according to the bearing bush blanks Set the parameters of the width adjusting device 5 and the thickness adjusting device 4;

[0050] Step (2): Turn on the feeding conveying device 1 and the blocking cylinder group 2 at the same time, set the running speed of the feeding conveying device to 1-4 m / min according to the size of the bearing bush blank to be processed, and the working frequency of the blocking cylinder group 2 2 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com