Steel angle sectional bar stacking machine and stacking method

A material palletizer and angle steel technology, which is applied to the packaging field of products of angle steel profile processing enterprises, can solve the problems of inability to complete the palletizing operation, low efficiency and high operating costs, and achieves reduction of production labor intensity and improvement of palletizing. Efficiency and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

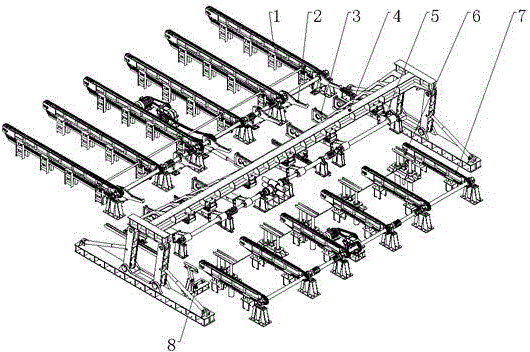

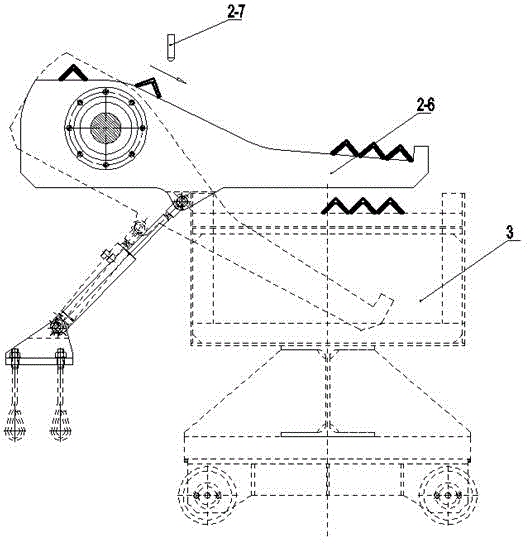

[0043] Referring to the accompanying drawings, an angle steel profile palletizer includes a feeding platform 1, a material distributing mechanism 2, a feeding trolley 3, a positive code mechanism 4, a negative code mechanism 5, a stacking lifting platform 6 and a stacking platform 7:

[0044] The feeding platform includes a support, a motor, a guide rail, a chain, two sprockets and a transmission shaft. The motor and the guide rail are fixed on the support, and one of the sprockets is arranged on the support and is movably connected with the support. , the other sprocket is set on the transmission shaft, and the motor is chain-connected with the transmission shaft through the transmission;

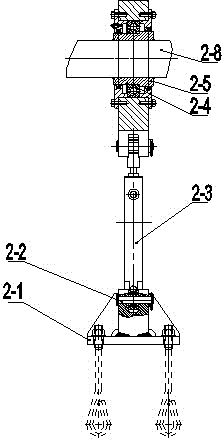

[0045] The material distribution mechanism includes a material distribution arm 2-6, a material distribution oil cylinder 2-3, a base 2-1, a pin shaft 2-2, a ball bearing 2-4, a fixed sleeve 2-5 and a photoelectric detection switch 2-7. The arm is installed on the transmission shaft 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com