Technology and equipment for arranging wiring terminals on motor coil framework

A technology of coil bobbins and terminals, applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of low production efficiency, cumbersome operation, large workload, etc., to ensure the assembly effect and improve work efficiency, The effect of the compression station

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

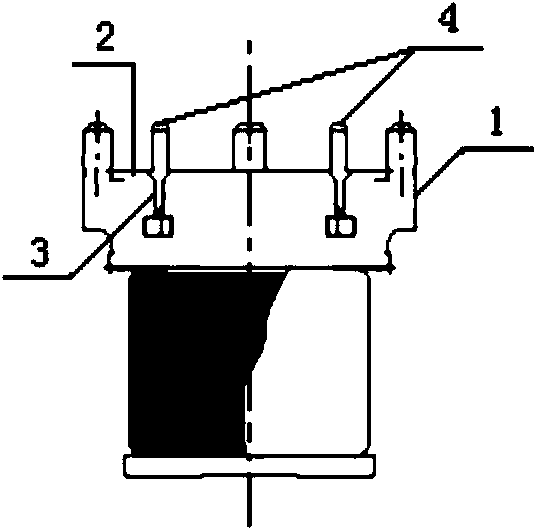

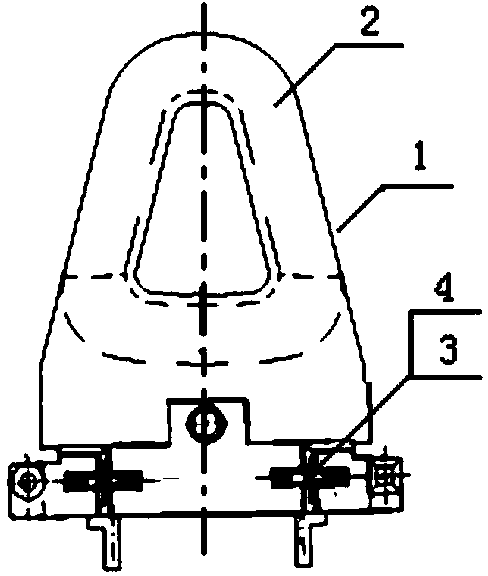

[0041] exist figure 1 , figure 2 Among them, the motor coil assembly related to the embodiment of the present invention mainly includes a coil skeleton (referred to as "skeleton") 1 composed of enameled wire wound on the skeleton, which is fixedly installed in the installation hole 3 on the end face 2 of the skeleton, so as to facilitate the connection with the coil. Two terminals (referred to as terminals) for electrical connection between the two ends of the lead wire and the positive and negative poles of the working power supply respectively.

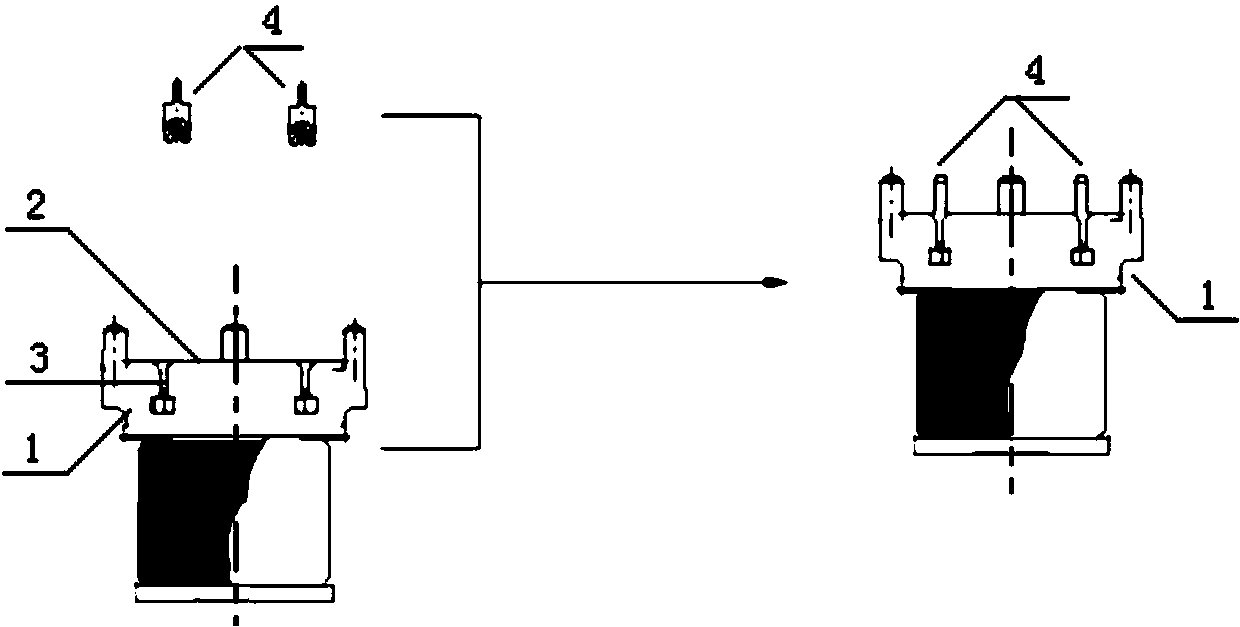

[0042] exist image 3 Among them, the process of arranging the connecting terminal on the motor bobbin of the present invention mainly includes the steps of inserting the connecting terminal 4 on the bobbin 1 and pressing and fixing the connecting terminal 4 on the end surface 3 of the bobbin.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com