Vertical tilting transport apparatus for domestic refuse

A technology for transfer device and domestic garbage, applied in the direction of garbage conveying, garbage collection, storage device, etc., can solve the problems of high building height, high consumption cost, large floor space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

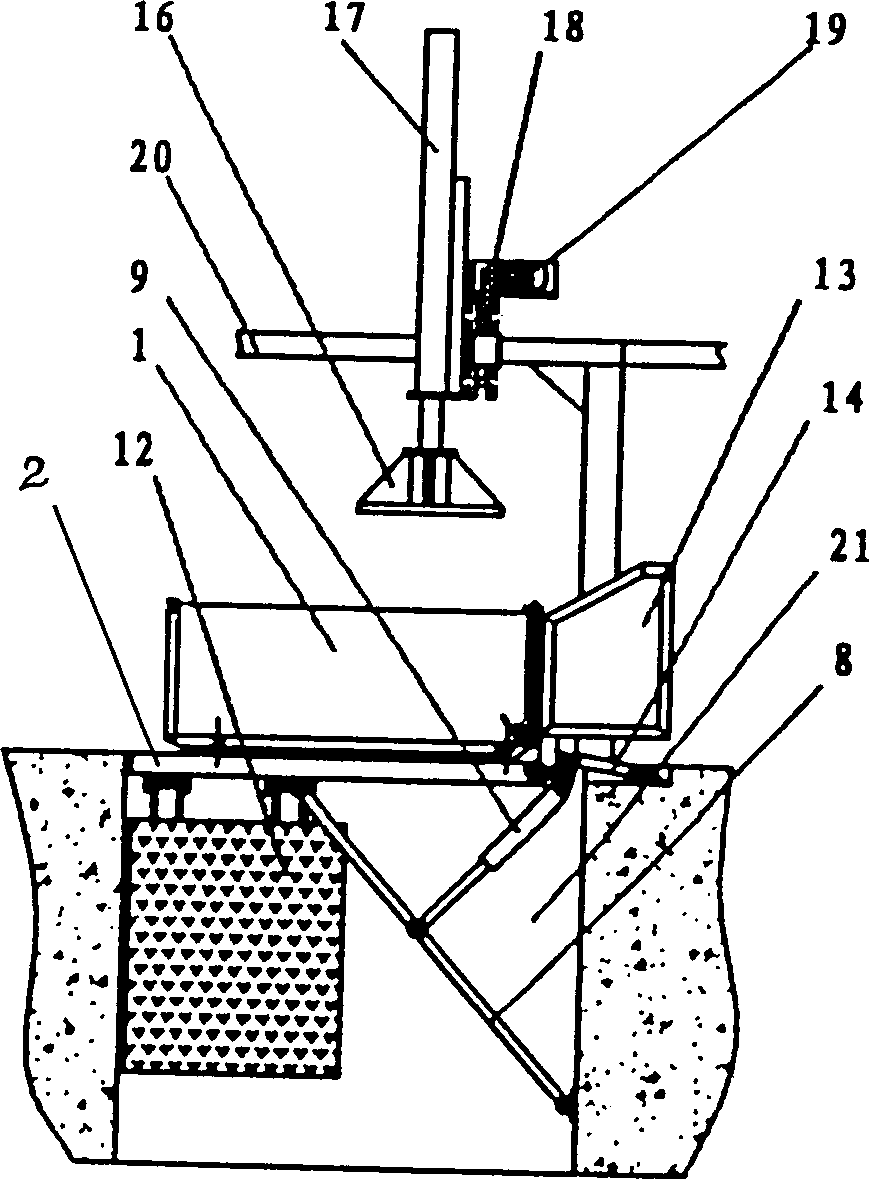

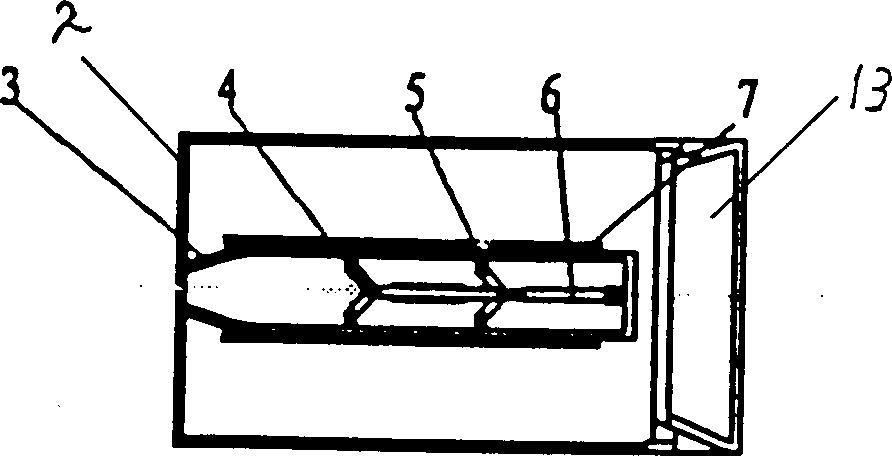

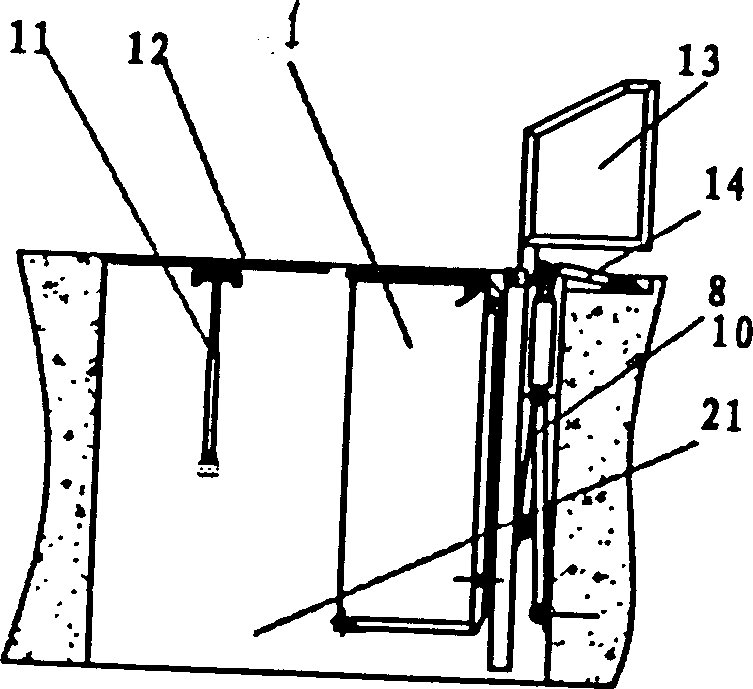

[0008] Please refer to the attached figure 1 As shown, a platform 2 is installed at the mouth of a pit 21, and the platform 2 is connected to the edge of the pit with hinges. The bottom of the platform 2 is affected by a hydraulic garbage rod 9, and can be turned up and down 90° from the pit mouth to the bottom of the pit. , the hydraulic pull rod 9 is driven by a hydraulic cylinder, the pull rod is connected with two folding arms 8, one folding arm 8 is connected with the bottom of the platform 2, and the other folding arm 8 is fixed to the pit wall. When the pull rod 9 shrinks, the folding arm 8 Retract towards the pit wall, and pull platform 2 to flip down 90°, see attached figure 2 , there are two positioning sides 3 in the center of the platform 2, and there is a locking mechanism in the middle of the two positioning sides 3, and two positioning rails 7 are installed on one side of the dustbin 1, and are slidingly embedded with the positioning sides 3 on the platform 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com