Vertical fixed-point garbage compressor

A garbage compressor and garbage technology, which is applied in the direction of garbage transmission, garbage collection, loading/unloading, etc., can solve the problems of inconvenient production, installation, construction, transportation and maintenance, large volume of vertical compressors, hidden safety hazards of operators, etc. Achieve high pushing force, reasonable structure, and reduce equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with specific embodiment, preparation method of the present invention is described in further detail:

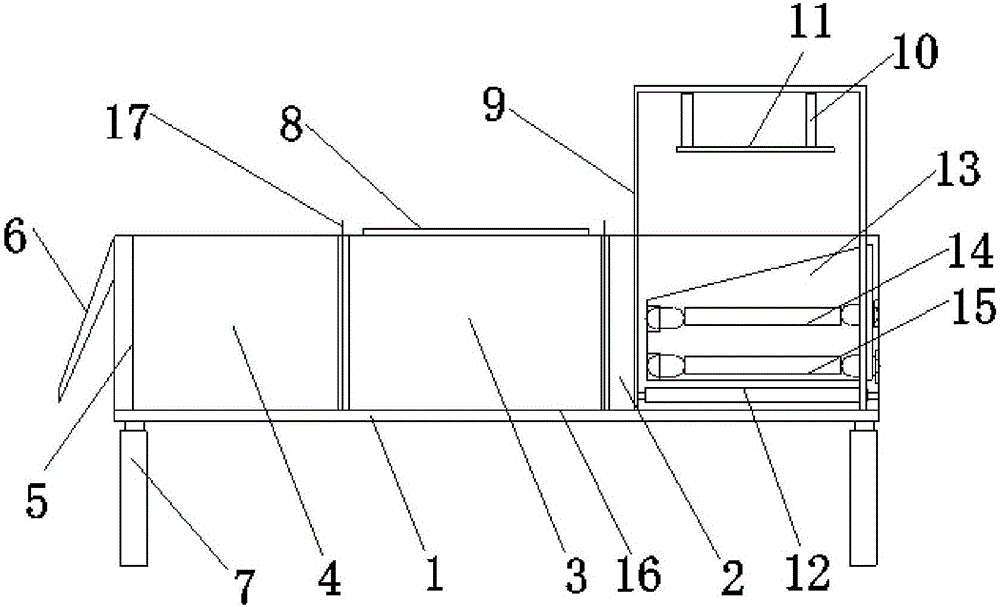

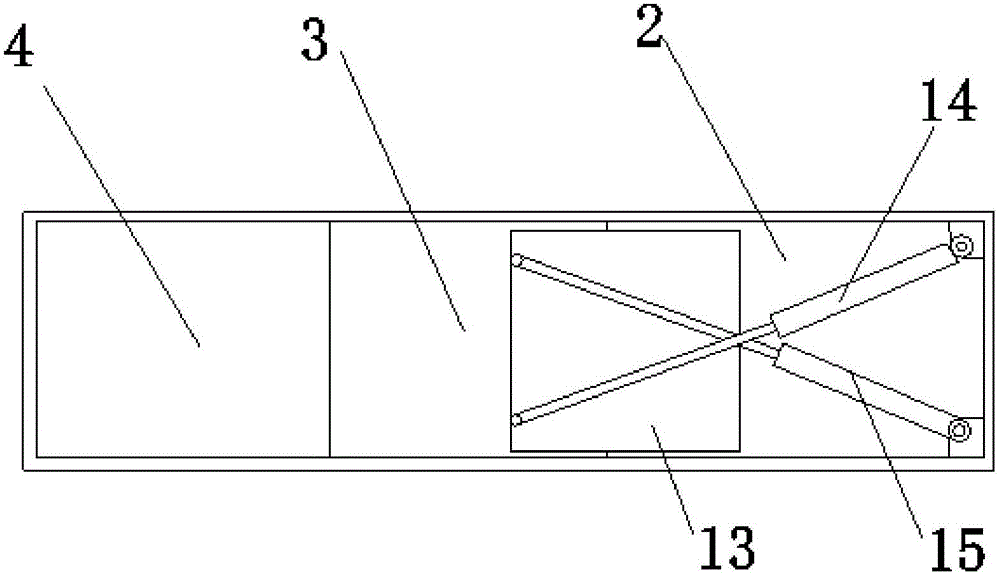

[0011] refer to figure 1 and figure 2 The shown vertical fixed-point garbage compressor includes a bracket 1, four hydraulic telescopic rods 7 are fixed on the bottom of the bracket 1, and a garbage box body is fixed above the bracket 1, and the garbage box body is sequentially divided from left to right It is a storage section 4 , a compression section 3 and an operation section 2 connected to each other, and the storage section 4 , the compression section 3 and the operation section 2 in the garbage bin are separated by an interposed partition 17 .

[0012] One side of the storage section 4 is provided with a garbage discharge port 5 and a flip baffle 6 is installed on the garbage discharge port 5; a garbage feed port 8 is provided above the compression section 3; A pushing mechanism is provided, and the pushing mechanism includes a first oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com