Progressive die 90-degree outward-opening adjustment and acute-angle bending structure

An acute-angle, right-angle technology, applied in the field of 90° outstretching adjustment and acute-angle bending structure, can solve the problems of complex processing, unstable production, inconvenient mold repair, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

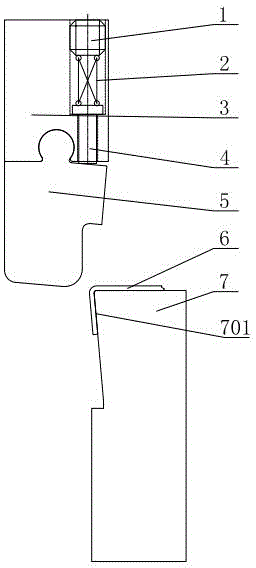

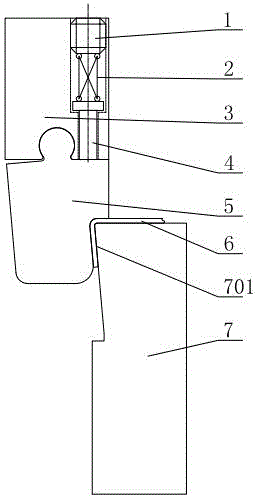

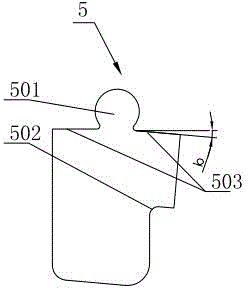

[0017] Such as figure 1 , figure 2 As shown, the continuous mold 90° external tension adjustment and acute angle bending structure of this embodiment includes a fixed insert 3, one end of the fixed insert 3 is provided with a counterbore, the lower part of the counterbore is equipped with a jacking pin 4, and the top of the counterbore is provided with a The stop screw 1, the stop screw 1 and the ejector pin 4 are connected through the spring 2; the swing punch 5 is installed under the fixed insert 3, such as image 3 , Figure 4 As shown, the structure of the swinging punch 5 is as follows: the middle part of the upper top surface of the swinging punch 5 is provided with an outwardly protruding punch 501, the upper top surfaces on both sides of the punching head 501 are slopes 503, and the lower end of the swinging punch 5 is on the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com