Numerical control laser carving machine

A CNC laser and engraving machine technology, which is applied in laser welding equipment, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems that the quality of workpiece engraving work is difficult to be guaranteed, the labor intensity of workers is high, and the degree of automation is low. The effect of ensuring product quality, reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

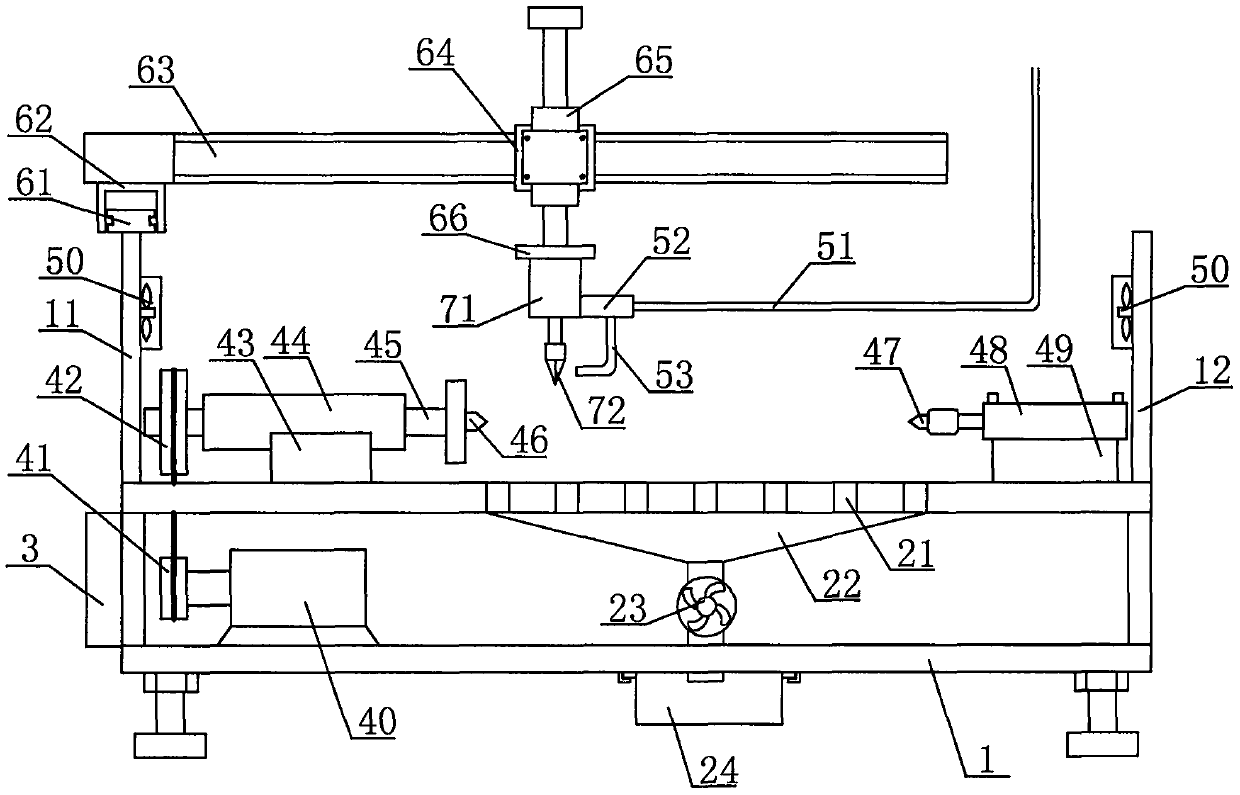

[0020] refer to figure 1 , the numerical control laser engraving machine of the present invention comprises:

[0021] 1. The support table assembly used to support the workpiece and drive the axis of the workpiece to rotate;

[0022] 2. The engraving machine head used to engrave the workpiece according to the set program;

[0023] 3. The displacement control mechanism that drives the movement of the engraving machine head;

[0024] 4. Water cooling device for cooling the engraving knife;

[0025] 5. Dust removal device for cleaning the dust generated by engraving;

[0026] 6. Numerical control device.

[0027] Specifically:

[0028] The support platform assembly includes a support platform 1, a workpiece rotating device and a workpiece fine-tuning device. The support platform 1 is a box-type structure, and a height-adjustable support foo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com