Full-automatic laser code engraving machine for tires

An engraving machine, fully automatic technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of automatic assembly line engraving, automatic positioning and clamping, etc., to reduce labor costs, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

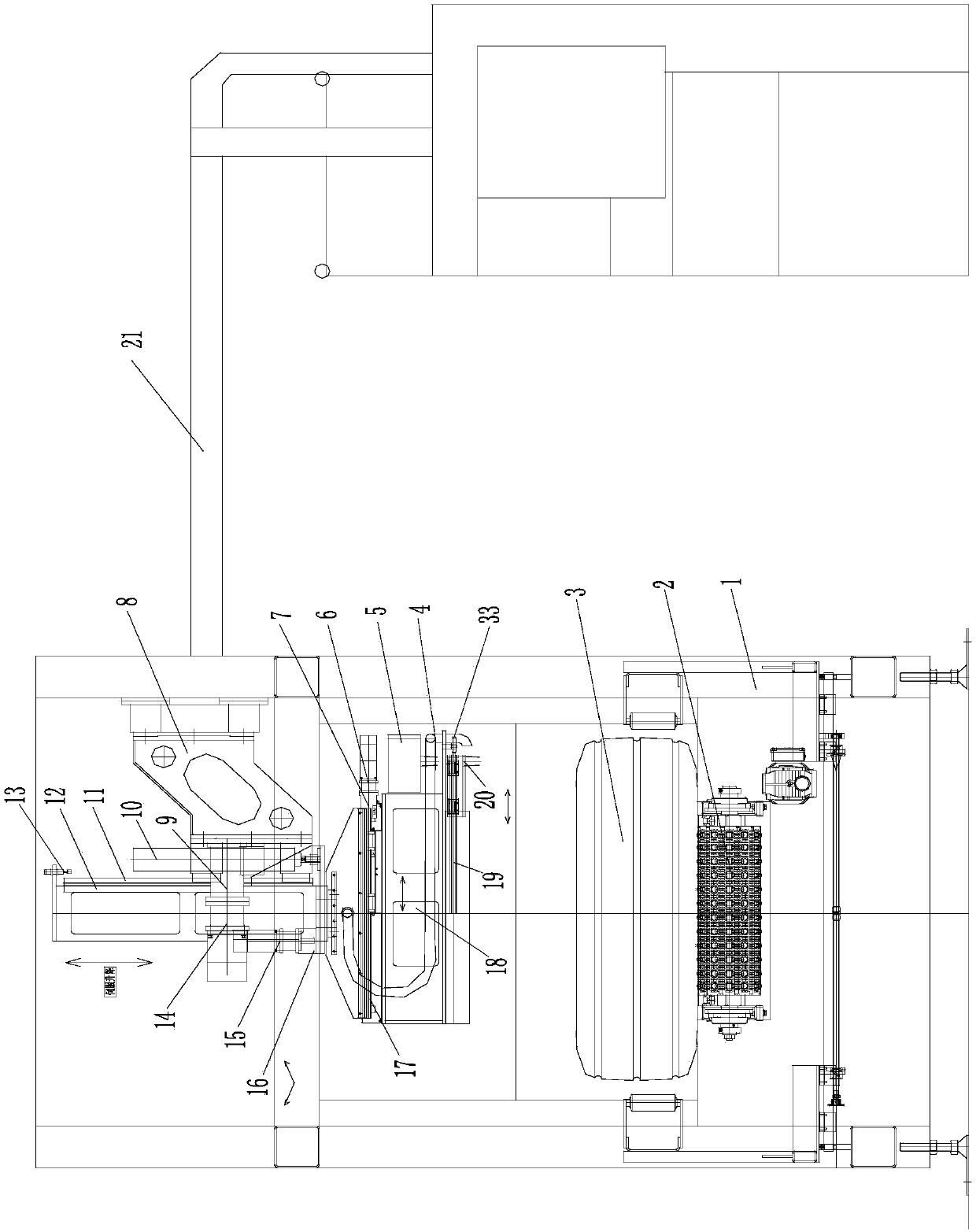

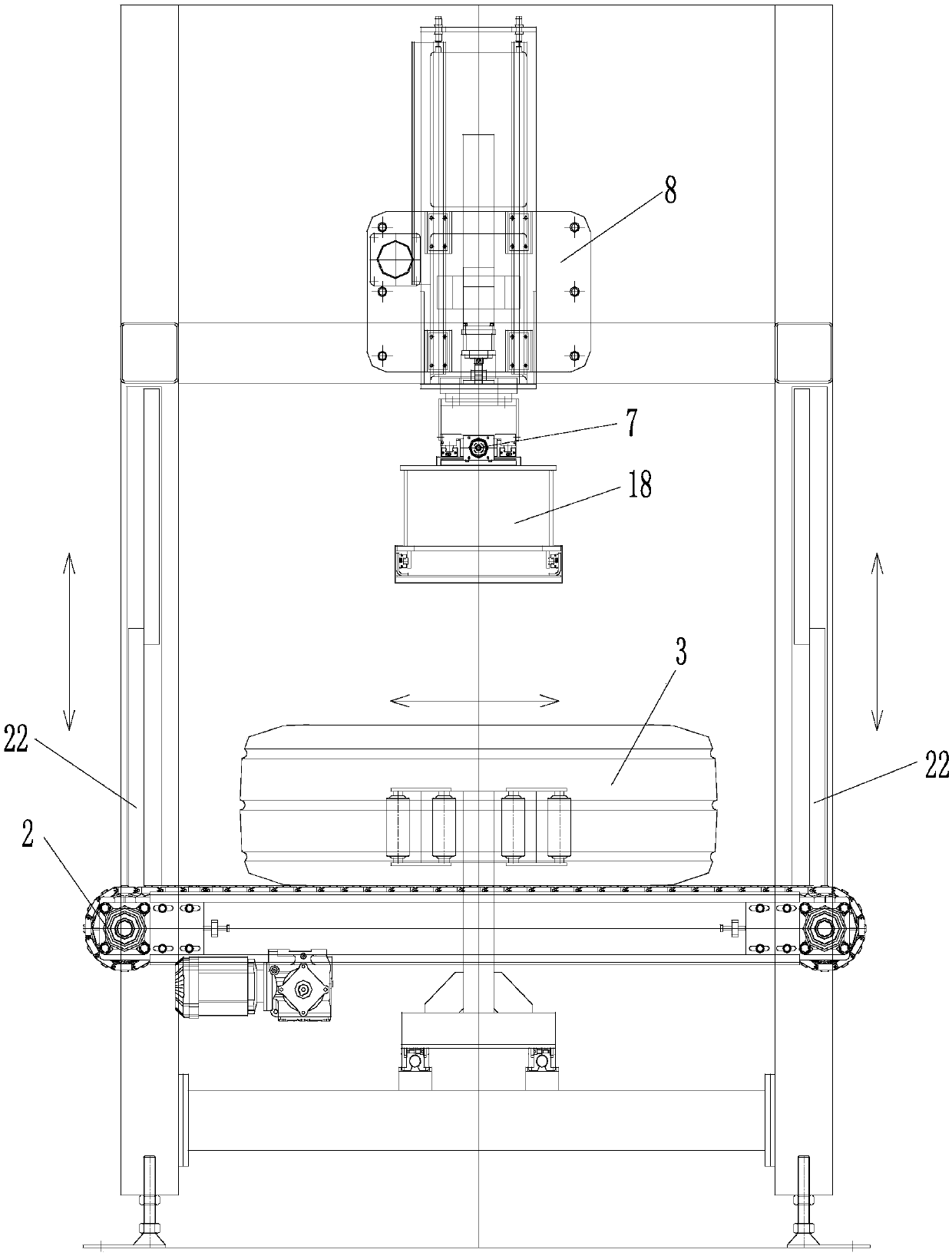

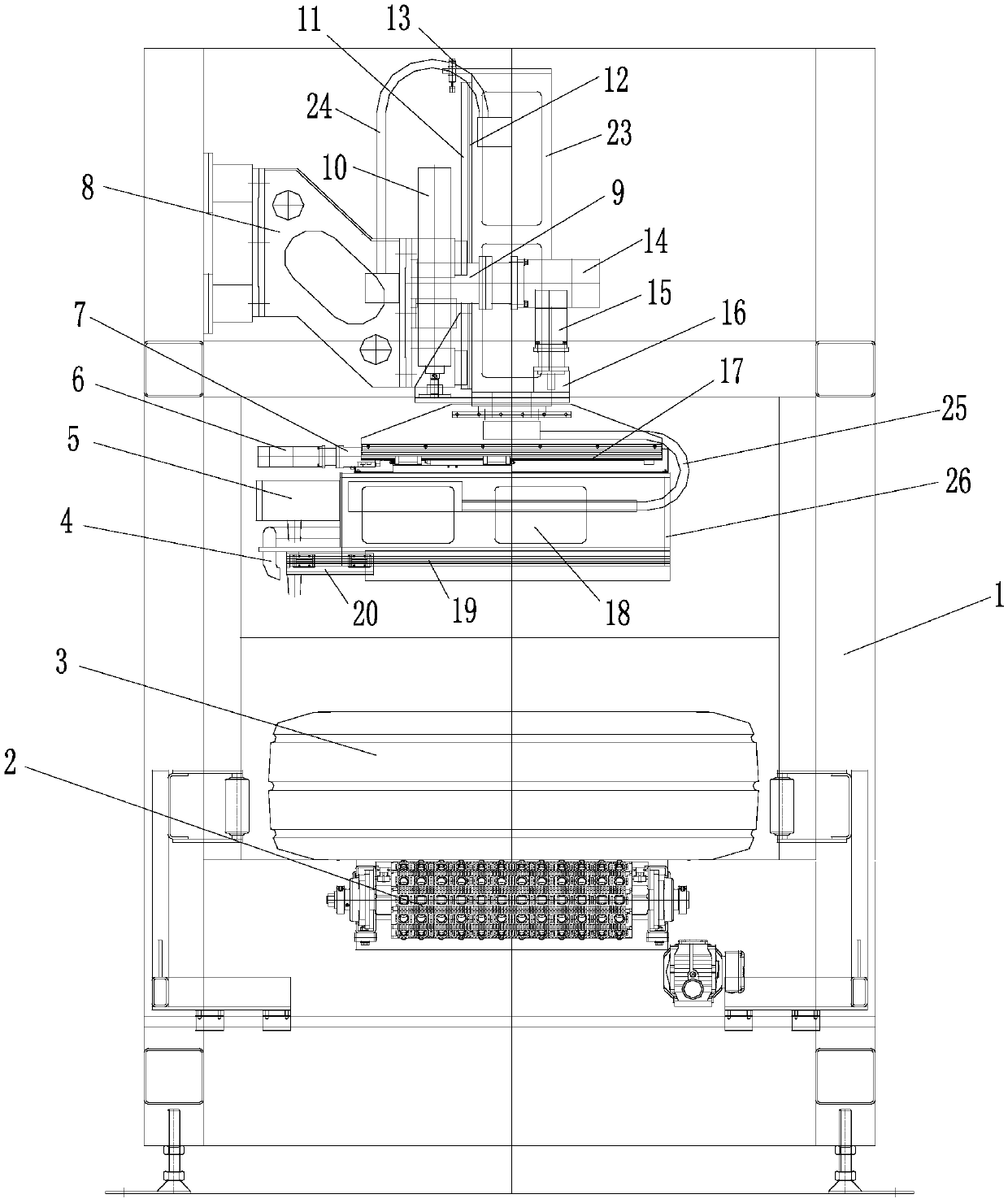

[0026] A kind of automatic tire laser engraving machine of the present embodiment, its structure is as follows Figure 1 to Figure 4 As shown, it mainly consists of frame body 1 with automatic opening and closing door 22, tire conveyor 2, automatic centering positioning and clamping mechanism, three-coordinate six-direction manipulator, laser head 5 (that is, CO2 laser engraving head), vision system, It is composed of smoke exhaust purification system and electrical software control system. One end of the frame main body 1 has a machine conveying inlet, and the other end has a machine conveying outlet, and an automatic opening and closing door 22 is respectively arranged at the machine conveying inlet and the machine conveying outlet, and the automatic opening and closing door 22 is a gate type driven by a door opening cylinder The door is connected to the control end of the electric cabinet 30 by the door switch cylinder arranged at the machine conveying entrance or the machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com