Prestressed high-strength concrete hollow support pile and manufacturing method thereof

A technology of high-strength concrete and concrete piles, applied to sheet pile walls, manufacturing tools, ceramic molding machines, etc., can solve the problems of piles that cannot be tightly bonded, hard-to-fix soil and waterstops, and twisted deformation of rubber waterstops , to achieve a good splicing fit, improve the overall stability, and ensure the overall stability of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing.

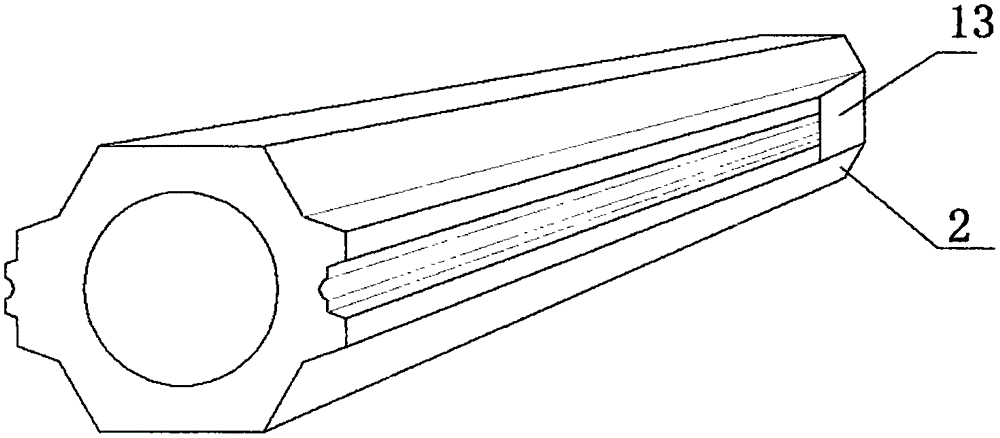

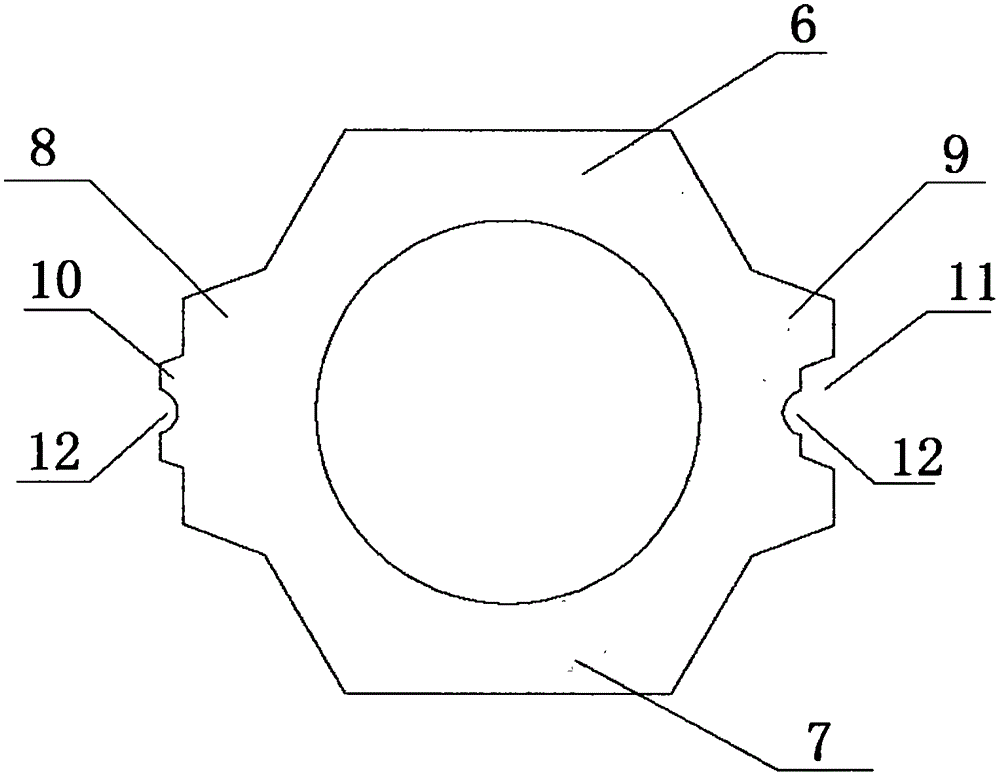

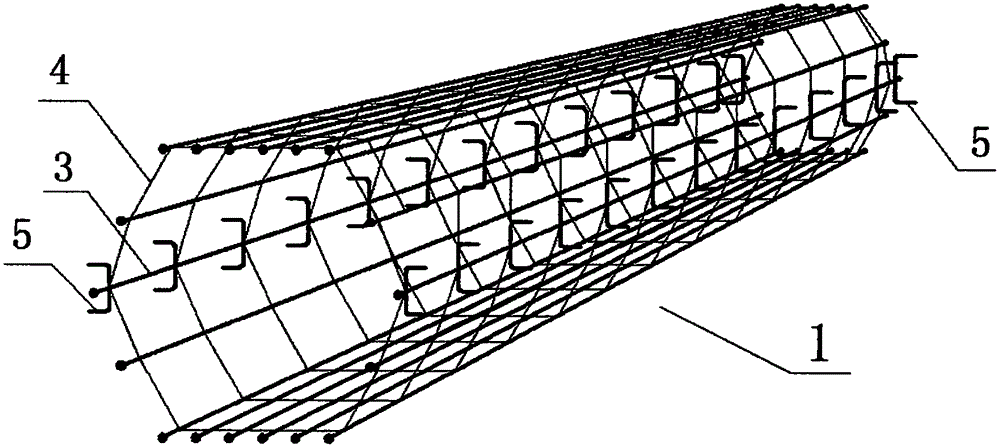

[0040] refer to Figure 1-8As shown, a kind of prestressed high-strength concrete hollow support pile provided by the present invention includes a reinforcement cage skeleton 1 and a concrete pile body 2, and the concrete pile body 2 is poured and wrapped on the reinforcement cage skeleton 1 and integrally formed with it; The cross-section of the prestressed high-strength concrete hollow support pile is polygonal hollow tubular, including the flange plate 6 on the pile body, the flange plate 7 under the pile body, the left leg of the pile body 8, the right leg of the pile body 9, the pile body body mortise 10 and pile body mortise 11; the flange plate 6 on the pile body and the flange plate 7 under the pile body are arranged symmetrically, and are all cross-welded by two or more longitudinal prestressed main reinforcements 3 and two or more ring stirrups 4 become; the flan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com