Pneumatic manipulator

A pneumatic manipulator and gripper technology, applied in the field of manipulators, can solve the problems affecting production efficiency and products, the location of clamping is not easy to determine, and the clamping is not easy to control, etc., to achieve high production efficiency, reliable performance, and simple debugging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

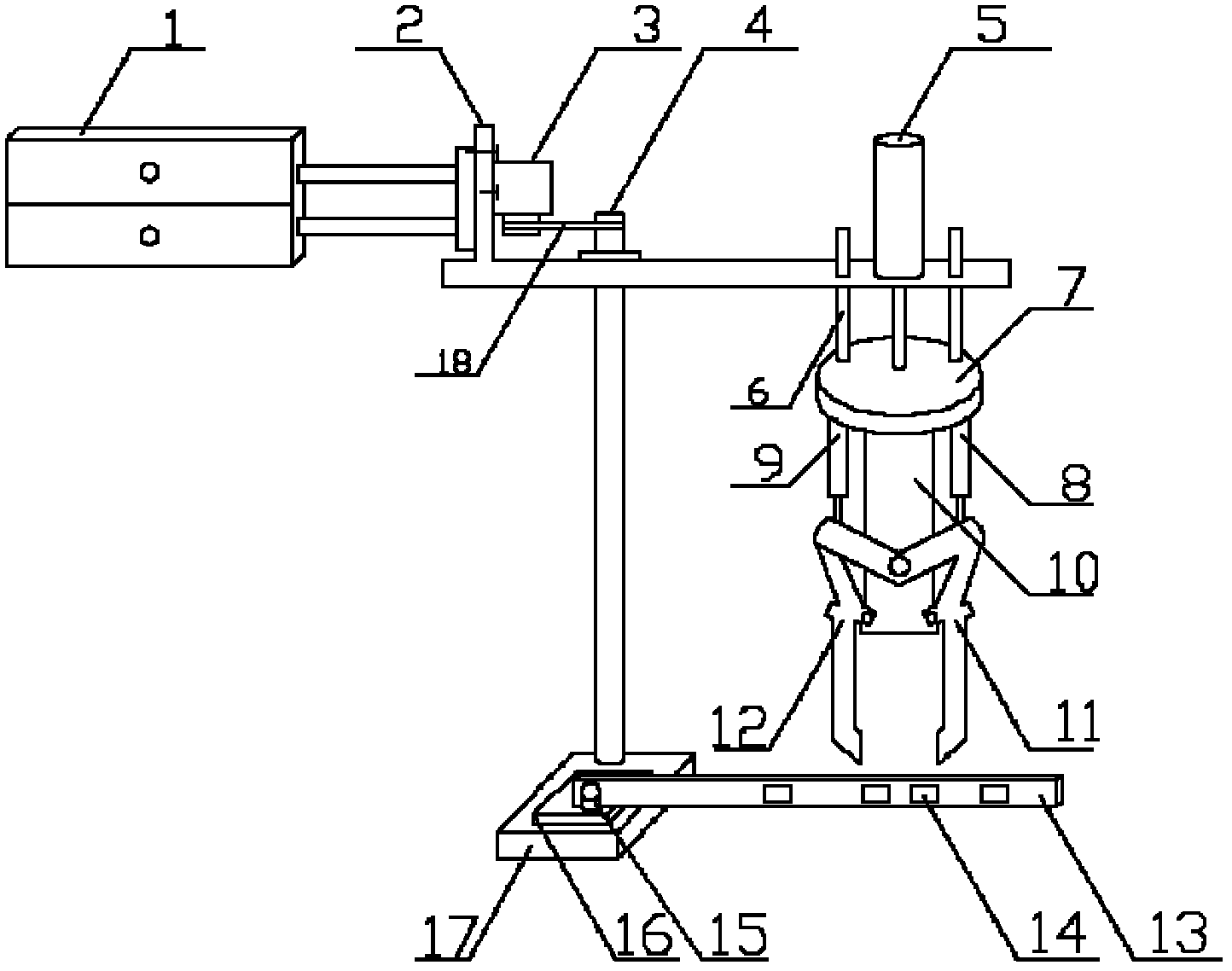

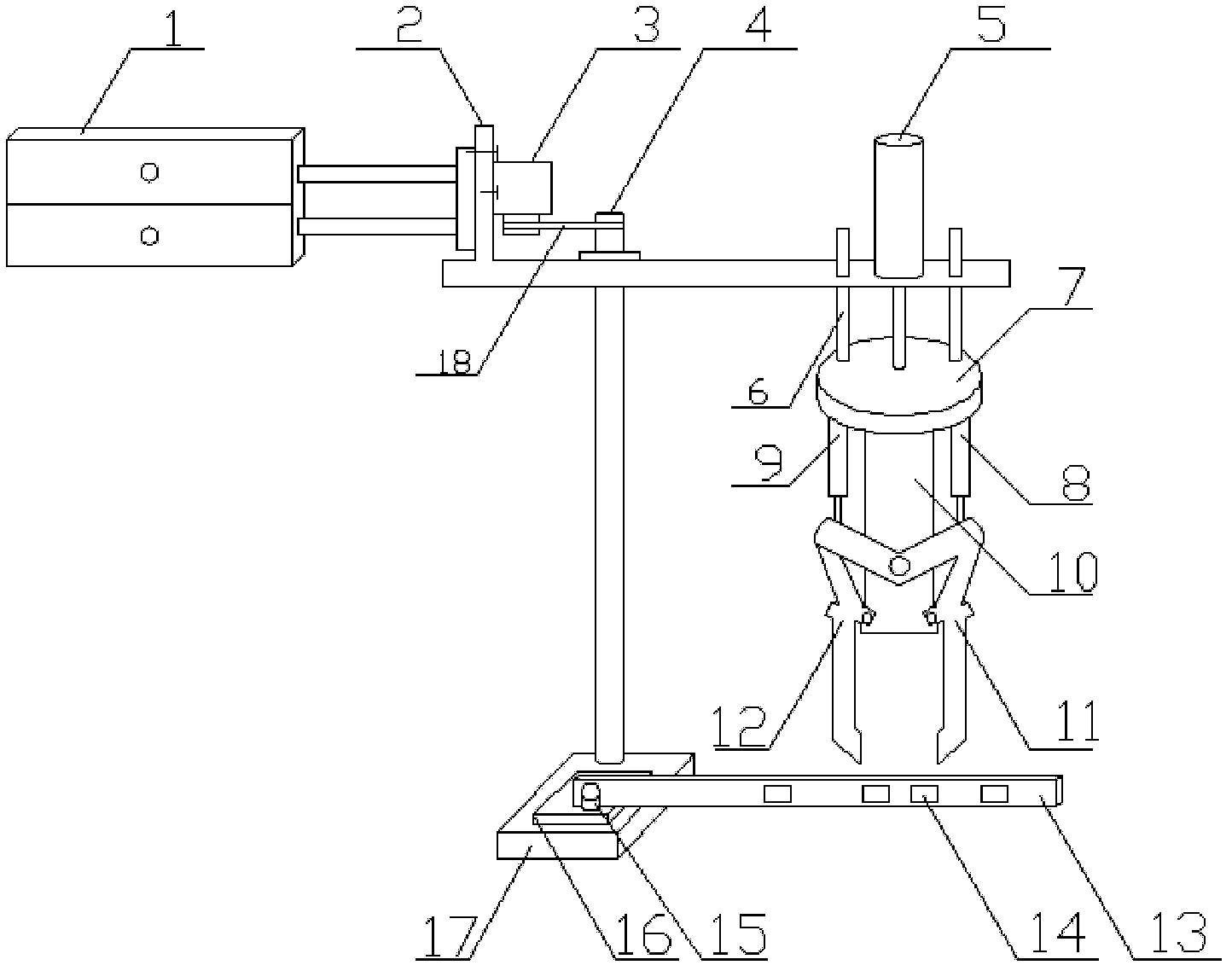

[0015] Such as figure 1 As shown, the base 17 is fixed when the present invention is in use, the base 17 is provided with a boss 16, the laser ranging sensor 15 on the boss 16 and the pressure strain gauge 14 on the beam 13 sense the workpiece on the production line, and the stepping motor 3 The rotating shaft 4 is driven by the conveyor belt 18 to rotate the fixed plate 2, the air cylinder I1 telescopically adjusts the position, the air cylinder II5 telescopically drives the fixed table 7 and the support column 6 to move, and the air cylinder III8 and the air cylinder IV9 drive the right finger connected to the support plate 10 11 and 12 left fingers to achieve tightening and relaxation.

[0016] Although the specific implementation of the present invention has been described above in conjunction with the accompanying drawings, it does not limit the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com