Large steel tube technology and equipment

A steel pipe and equipment technology, applied in metal processing equipment, welding equipment, welding equipment, etc., can solve the problems of difficult construction safety control, increased technical difficulty, and improved steel pipe construction safety and efficiency, and achieve the improvement of the automation level of manufacturing and installation machinery , Reduce the difficulty of hoisting and transportation, and reduce the effect of engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

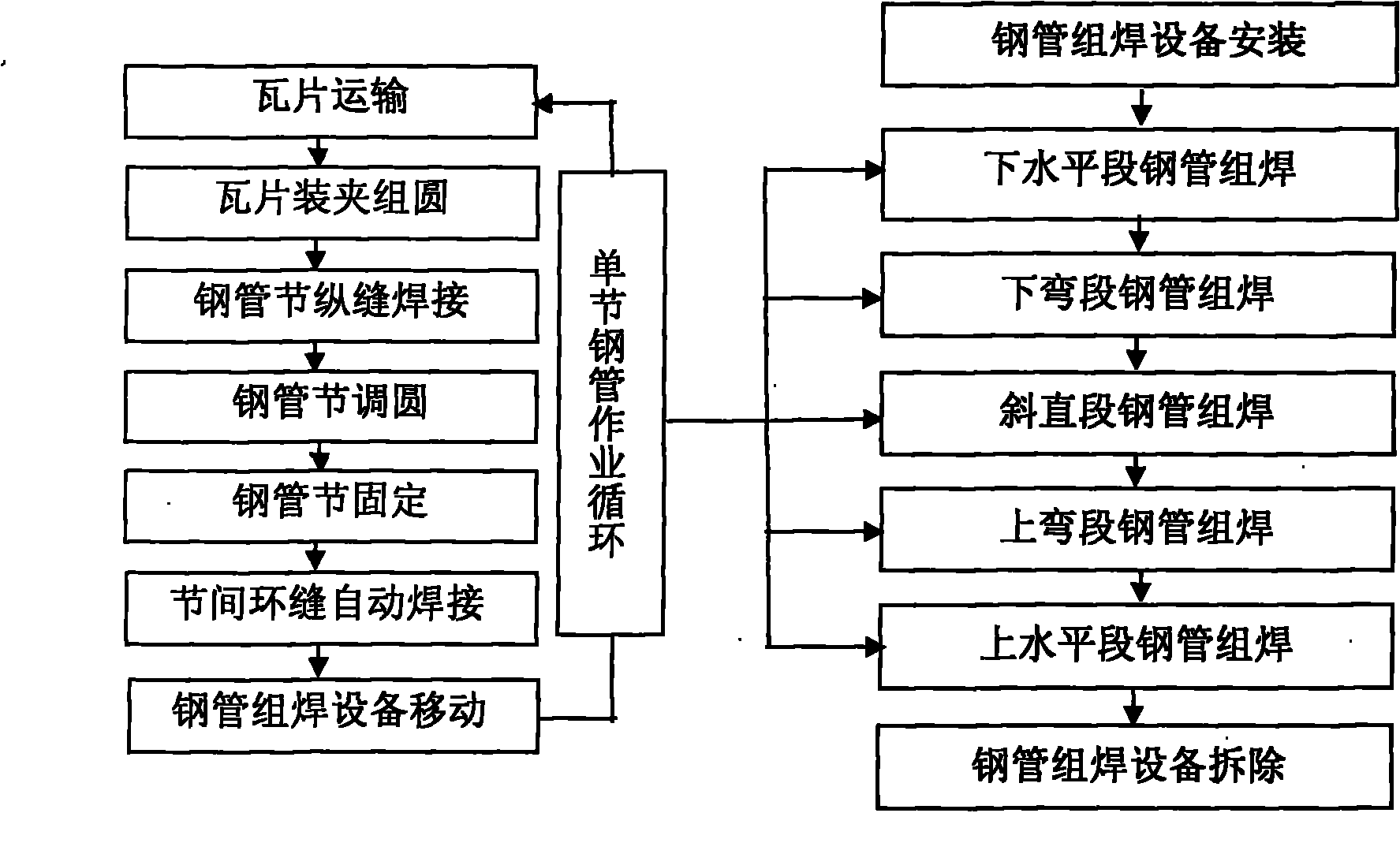

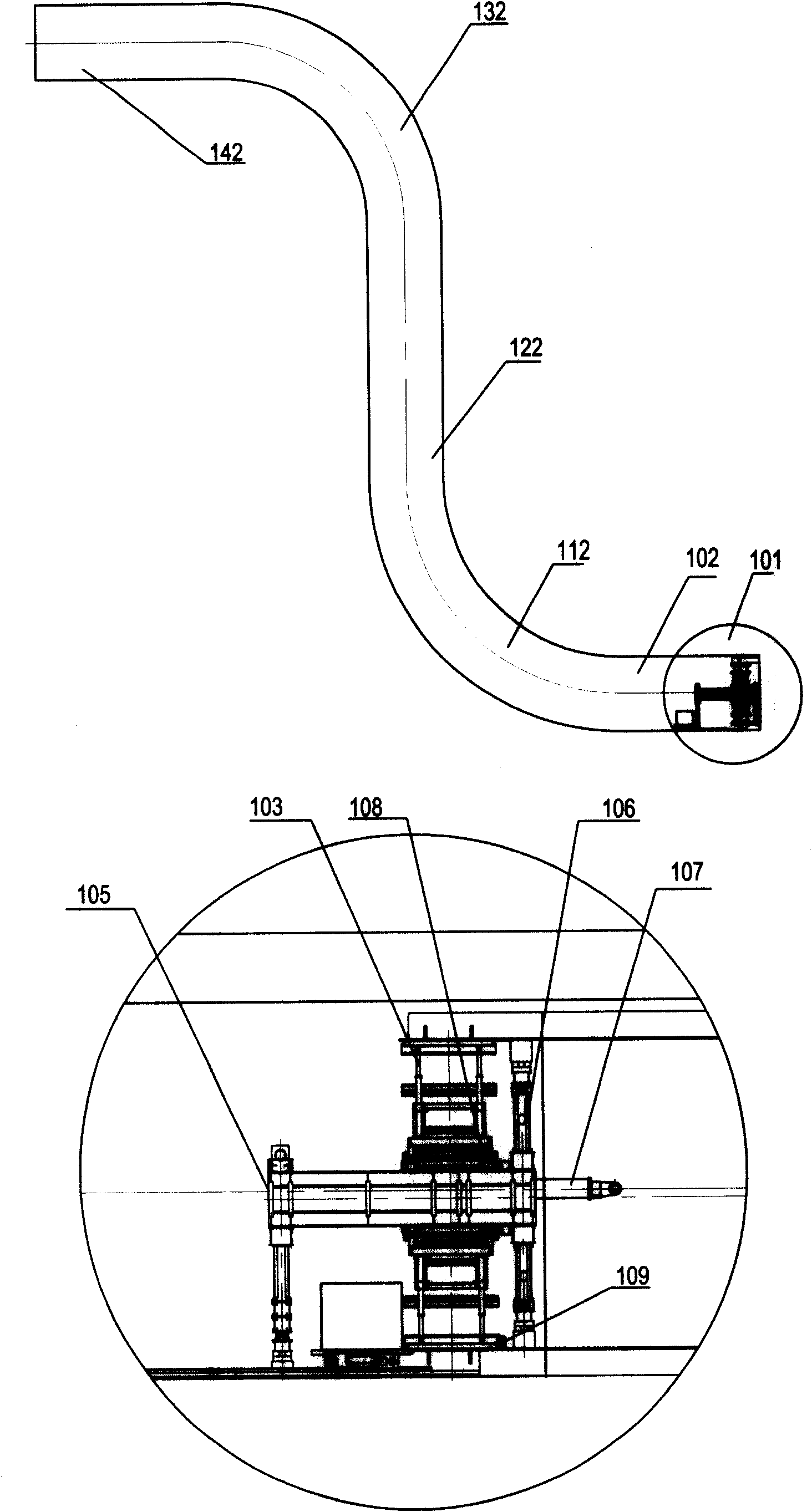

[0016] Embodiment 1: The manufacture and installation process and equipment of large-scale water delivery steel pipes in a hydropower station cavern, such as figure 2 As shown, the construction process is as follows: 1. Steel plate discharge and scribing; 2. Steel pipe sheet blanking; 3. Steel pipe sheet processing; 4. Steel pipe curled into tiles; 5. Tile inspection; 6. Steel pipe welding equipment (101) Installation and commissioning in the lower horizontal tunnel; 7. Tile transportation, including long-distance transportation to the construction tunnel, or secondary transportation to the construction tunnel of the lower horizontal tunnel after storage, and the tiles are transferred to the track trolley, using the inner track Transporting tiles; 8. The lower horizontal section of the steel pipe (102) is mechanically assembled on the welding equipment (101); 9. The longitudinal seam welding of the steel pipe section; Radius control; 11. Installation and welding of the stiffe...

Embodiment 2

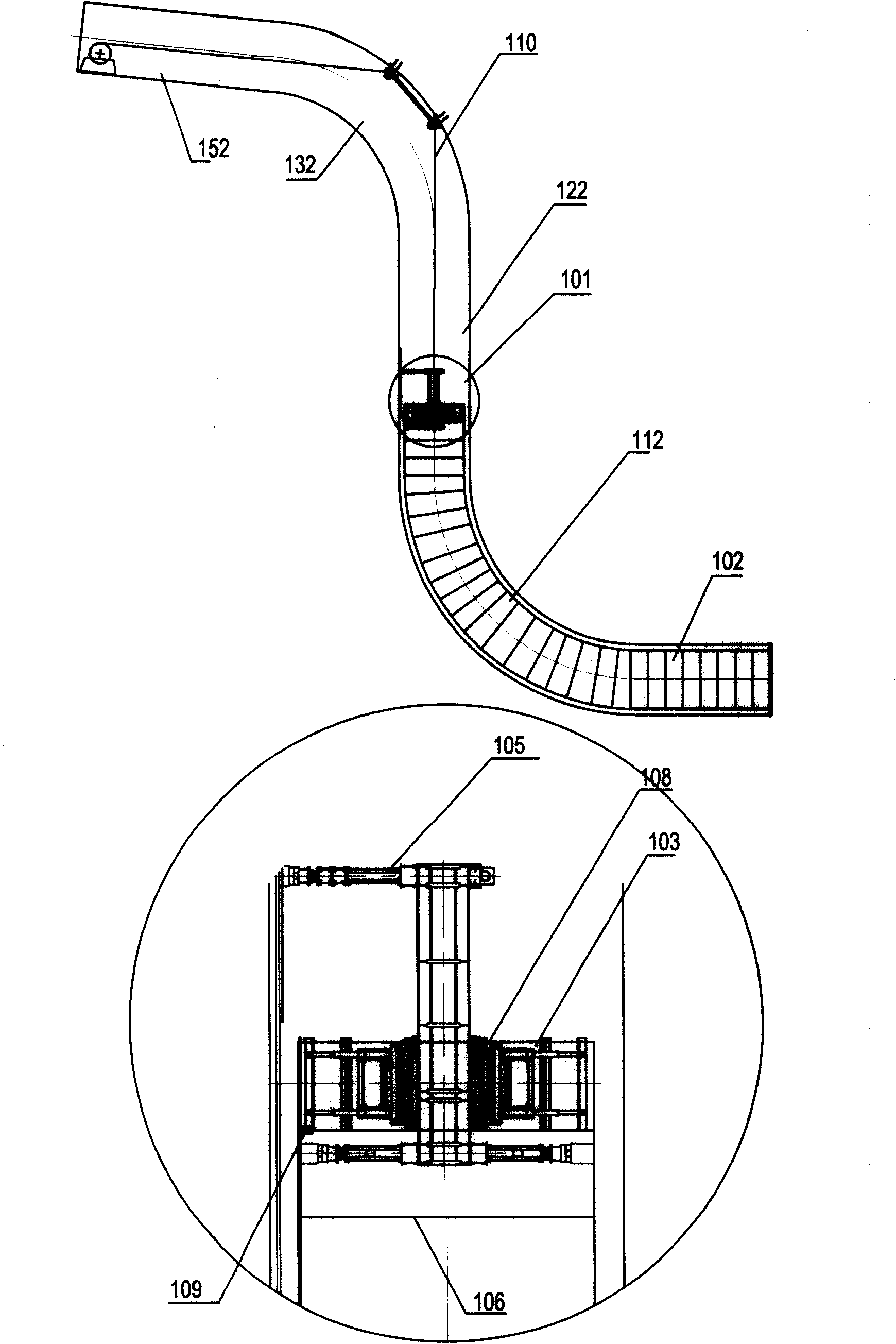

[0018] Embodiment 2: The manufacture and installation process and equipment of large-scale water delivery steel pipes in a hydropower station cavern, such as figure 2As shown, the construction process is as follows: 1. Steel plate discharge and scribing; 2. Steel pipe sheet blanking; 3. Steel pipe sheet processing; 4. Steel pipe curled into tiles; 5. Tile inspection; 6. Steel pipe welding equipment (101) Install and debug in the lower horizontal hole, and install the winch lifting mechanism (110); 7. The tiles are transported and transferred to the track trolley, and the tiles are transported by the inner track of the pipe; 8. The first steel pipe in the lower bending section (112) 9. Steel pipe joint longitudinal seam welding; 10. Steel pipe joint adjustment: use the stroke adjustment on the rotary support (103) to control the radius; 11. Steel pipe joint longitudinal seam position Stiffening ring installation and welding; 12. The position adjustment of the first steel pipe ...

Embodiment 3

[0020] Embodiment 3: The manufacture and installation process and equipment of water delivery steel pipes in a large dam of a hydropower station, such as Figure 4 As shown, the construction process is as follows: 1. Steel plate discharge and scribing; 2. Steel pipe sheet blanking; 3. Steel pipe sheet processing; 4. Steel pipe curled into arc tiles; 5. Stiffening ring manufacturing, installation and welding; 6. The tiles are inspected and delivered; 7. The steel pipe assembly and welding equipment (101) is installed and debugged in the lower horizontal section (102); 8. The tiles are transported to the working range of the crane or cable lifting equipment and hoisted to the assembly and welding equipment; 9. The steel pipe of the lower horizontal section (102) is rounded on the assembly welding equipment (101); 10, steel pipe section longitudinal seam welding; 11, steel pipe section adjustment garden; 12, steel pipe section longitudinal seam stiffening ring installation and wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com