Laminator for automatically tearing film on lower cover

A laminating machine, automatic technology, applied in the direction of lamination device, lamination auxiliary operation, lamination and other directions, can solve the problems of inability to form flow operation, inability to improve the efficiency of tearing, and repetitive labor, etc. The effect of simple structure, avoidance of loss and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

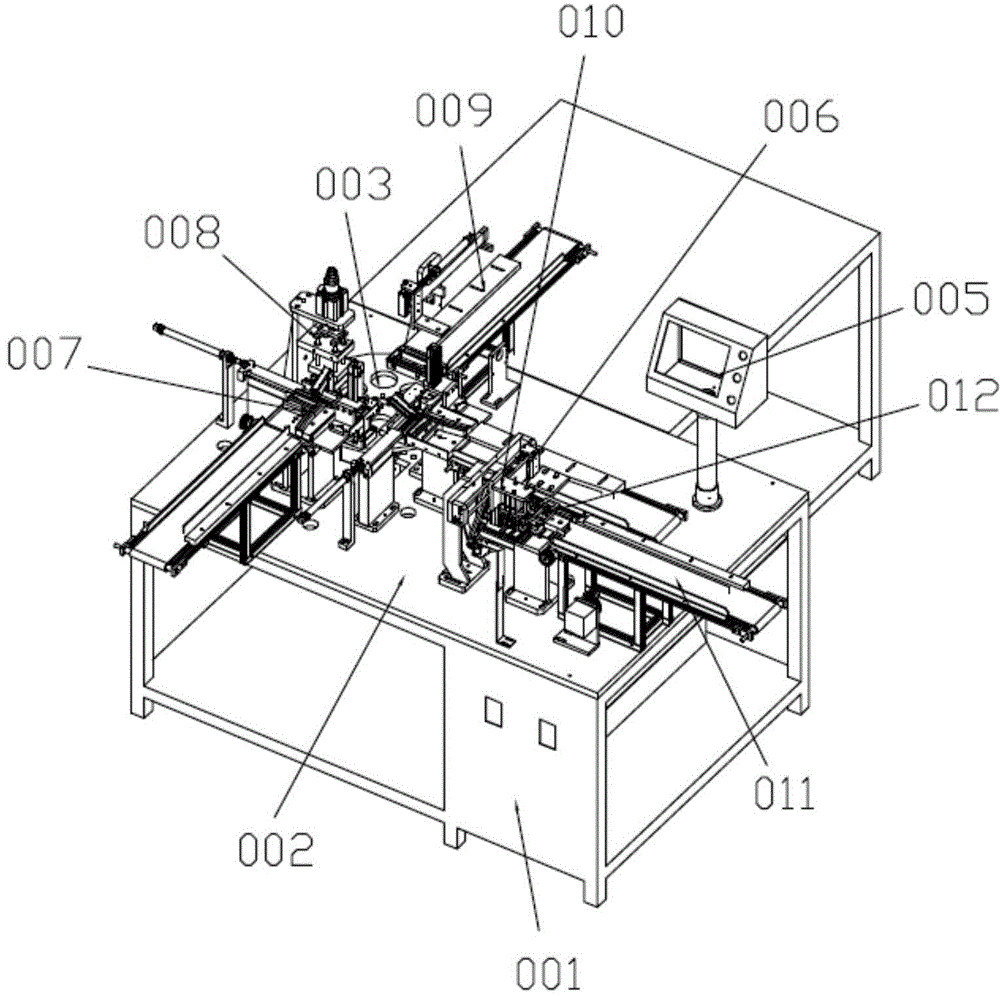

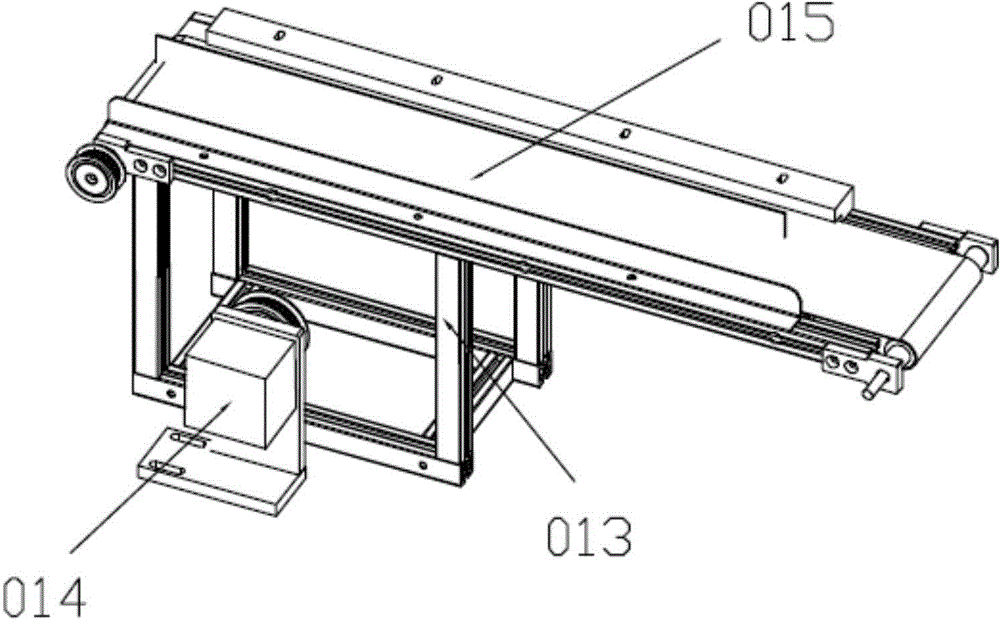

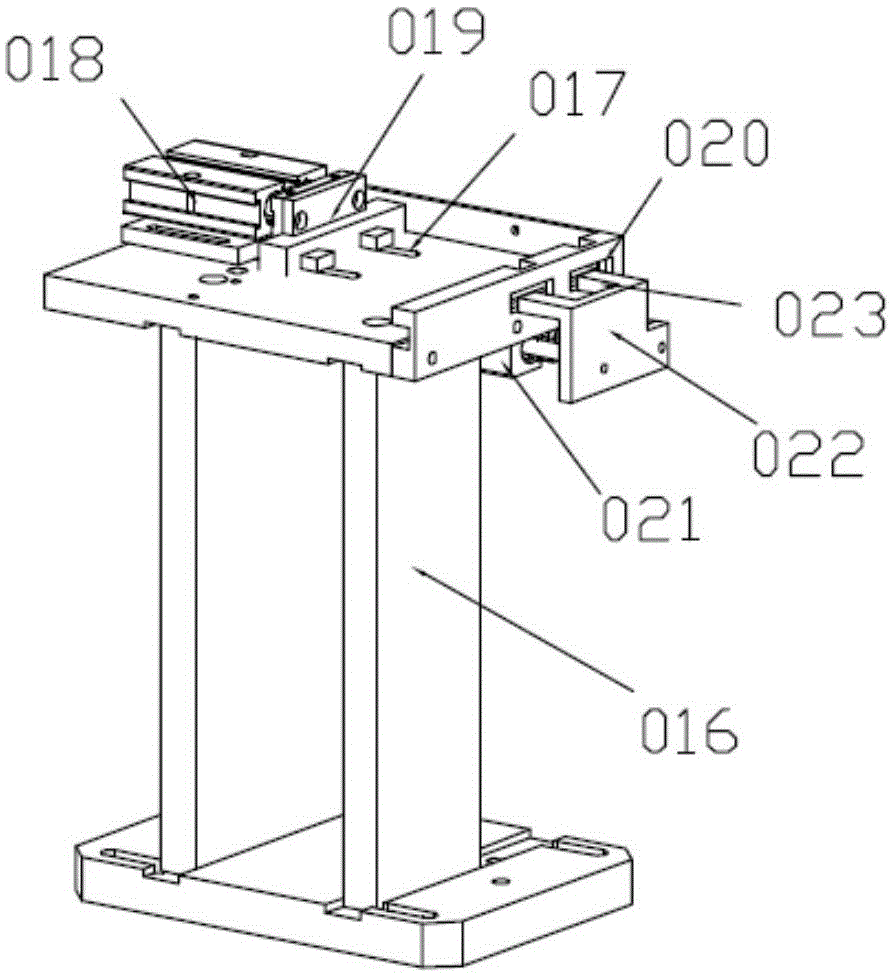

[0026] Figure 1 to Figure 10 Schematically shows a lower cover automatic tearing glue bonding machine according to the present invention.

[0027] This embodiment provides a lower cover automatic tear glue laminating machine, please refer to figure 1 , comprising: a machine base 001, a working platform 002 is provided on the upper end of the machine base 001, an indexer 003 is arranged on the working platform 002, and a jig 004 for loading materials is arranged on the indexer 003, and in the The indexer 003 is surrounded by a control device 005, an aluminum box feeding mechanism 006, a film feeding mechanism 007, a pressing mechanism 008 and a discharging mechanism 009, and a tear-off paper is provided on the side of the aluminum box feeding mechanism 006. The material shifting mechanism 010 is provided with an aluminum box automatic feeding mechanism 011 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com