Pneumatic air exhaust system

A pneumatic and damper technology, applied in the field of exhaust, can solve the problem that the exhaust system cannot fully exhaust and exchange air in a timely manner, and achieve the effect of ensuring smooth exhaust, preventing airflow recharge, and ensuring freshness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

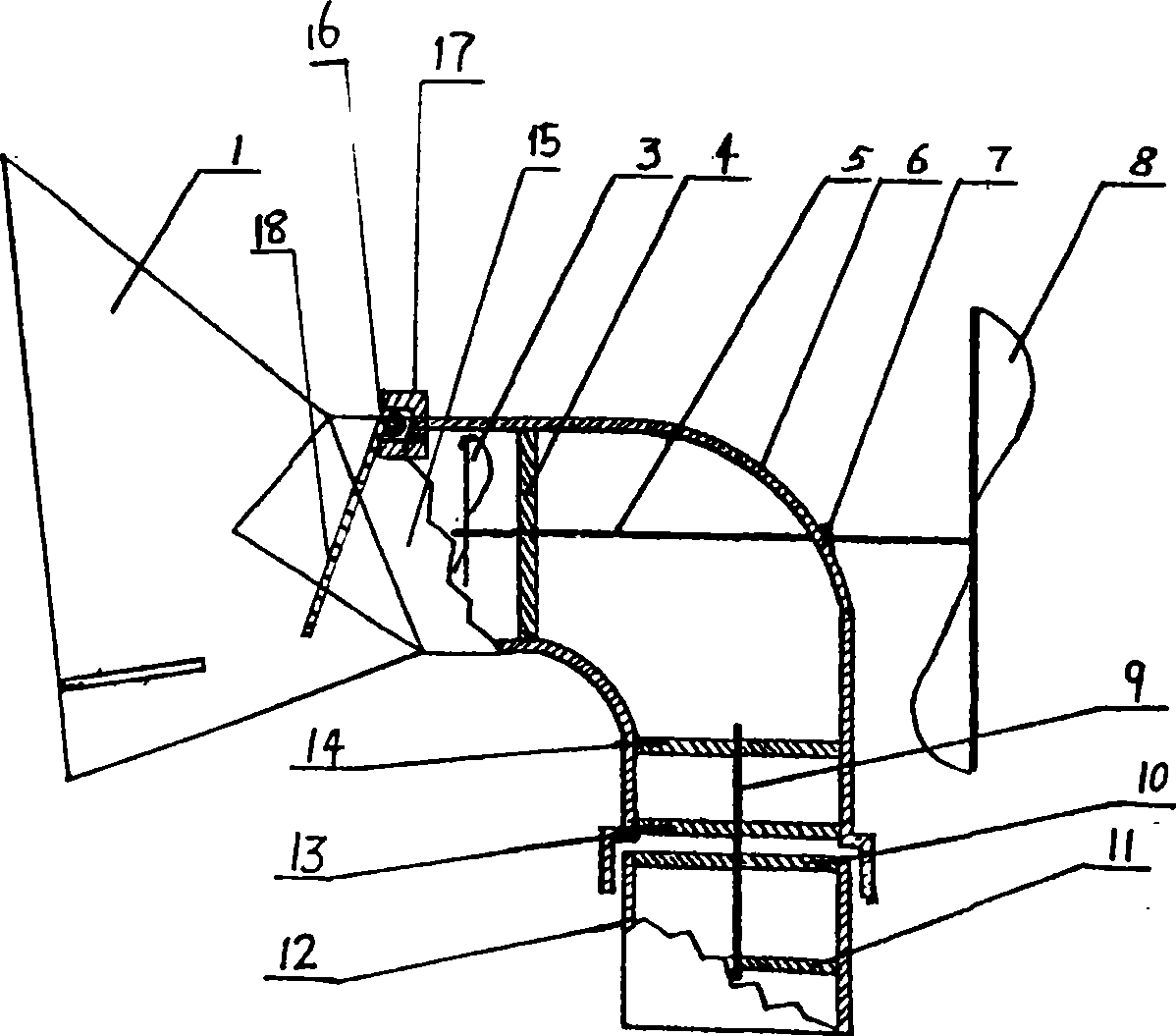

[0014] The pneumatic exhaust system includes a fixed air channel 12, a rotating air channel 6, an exhaust fan 3, a pneumatic fan 8, an empennage 1, a damper 16 and an air outlet.

[0015] The lower end of the fixed air channel 12 is connected to the indoor chamber, and its upper end is connected to a rotating air channel 6 . The connection mode is that the fixed air passage is provided with a first support 11 for the fixed air passage and a second support 10 for the fixed air passage, and the lower end of the fixed shaft 9 is fixed on the above two supports; The first support 13 of the airway and the second support 14 of the rotating airway, the upper end of the fixed shaft 9 is fitted on the above-mentioned two rotating airway supports through a bearing; or the lower end of the fixed shaft 9 is fitted on the above-mentioned two fixed airway supports through a bearing; or Both ends of the fixed shaft are matched by bearings, and the lower end of the rotating air passage is sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com